Heat exchanger for food safety food grade milk dishes

-

Supplier: Anhui Yingchuang Laser Technology Co., Ltd. -

Region: Anhui, China -

Contact: Ms Mary Yang -

Price: $50.00 / >=20 pieces -

Min. Order: 20 pieces

| strength: | required | Core Components Warranty: | 1 year |

| weight: | 45kg | greatest pressure: | 2MPa (20 bar) |

| Heat transfer area: | 5.8 square meters | Mechanical test report: | Not available |

| Packaging Details: | 50 pieces in a wooden box (custom packaging accepted) | Material: | 304 stainless steel plate |

| Showroom location: | not any | Processing: | heat exchanger |

| Warranty: | 1 year | Maximum operating temperature: | 600 degrees Celsius |

| Applicable industries: | Manufacturing plants, food and beverage plants, energy and mining, heat exchange | model: | YC-122401-304 |

| Dimensions (L*W*H): | custom made | payment terms: | letter of credit, wire transfer |

| Packaging Preview: | size: | 1200x2400x(1.0 x 2)mm | |

| Health status: | new | place of origin; place of origin: | Anhui, China |

| Processing Type: | milk | port: | Shanghai or Ningbo |

| Supply capacity: | 100 pieces per week | Video external inspection: | if |

| Marketing Type: | customizable | product name: | Safe Food Grade Milk Plate Heat Exchanger |

| Core components: | heat exchange plate | brand: | not any |

| Voltage: | 220v/380v/custom |

Safe Food Grade Milk Plate Heat Exchanger

describeMilk Plate Heat Exchanger

| Numbering. | Dimensions (LxWxL) (mm) | Material: Stainless steel) | Maximum operating temperature (°C) | Maximum pressure (MPa) | Heat transfer area (M² / PC) | Weight (KG/PC) |

| YC-152501-304 | 1500x2500 (1.0x2) | 304 | 600 | 2 | 7.5 |

60 |

| YC-151501-304 | 1500x1500 (1.0x2) | 304 | 600 | 2 | 4.5 | 36 |

| YC-122401-304 | 1200x2400 (1.0x2) | 304 | 600 | 2 | 5.8 | 46 |

| YC-062001-304 | 600x2000 (1.0x2) | 304 | 600 | 2 | 2.4 | 19 |

| YC-152501-316L | 1500x2500 (1.0x2) | 316L | 600 | 2 | 7.5 | 60 |

| YC-151501-316L | 1500x1500 (1.0x2) | 316L | 600 | 2 | 4.5 | 36 |

| YC-122401-316L | 1200x2400 (1.0x2) | 316L | 600 | 2 | 5.8 | 46 |

| YC-062001-316L | 600x2000 (1.0x2) | 316L | 600 | 2 | 2.4 | 19 |

| YC-122401-2205 | 1200x2400 (1.0x2) | 2205 | 600 | 2 | 5.8 | 46 |

| YC-062001-2205 | 600x2000 (1.0x2) | 2205 | 600 | 2 | 2.4 | 19 |

Accept any other special shape and size design custom

Milk Plate Heat Exchangeris a highly versatile plate heat exchanger that can be welded, formed or installed to meet your exact needs. It can be applied in irregular shapes,

In high pressure, high temperature or corrosive environments.

Thermal efficiency typeMilk Plate Heat Exchanger

1. Immersion heating and cooling

2. Can be heated, cooled or insulated outside the container

3. Built-in heating or cooling, such as internal heating fluidized bed

4. Special heat exchanger

5. Evaporator, condenser

6. Clamp heating, cooling and temperature holding

7. Polymerizer cooling, heating baffle

8. Refrigerator

9. Plate heat recovery group

10. Roller insulation

11. Equipment slot jacket

12. Conical head jacket

13. Dye heater

14. Flue gas heat recovery board group

15. Falling film cold water (salt water) unit

16. Built-in concentrator or reboiler

17. Large built-in baffle set for cooling vegetable oil

feature

1. Available in most materials such as stainless steel 304, 316L, 2205 and titanium

2. High operating pressure

3. High working temperature

4. No need for gaskets

5. Corrosion resistance

6. Easily shape to fit the shape you need

7. Easy to provide incision

8. Heat transfer type of thermal efficiency

9. Immersion heating and cooling.

10. Clip-on heating, cooling and temperature holding

11. Integral jacket for heating and cooling

12. Custom heat exchanger design

13. Evaporator

14. Condenser

15. Easy-to-clean, beautiful finishes are available

16. Low pressure drop design

17. Available in pharmaceutical and food grade designs

18. Provides a more active heat transfer surface

typeMilk Plate Heat Exchanger

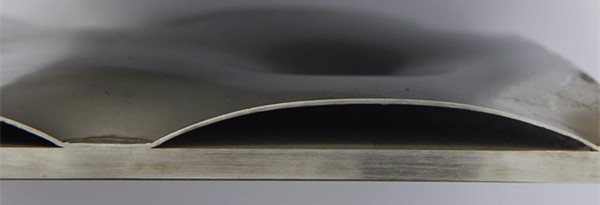

Double relief

Double-sided pressure forming, typically used for most applications

It is suitable for heating and cooling process, generally the thickness of both sides is the same.

The material can be stainless steel, Hastelloy, carbon steel, etc. Different materials and thicknesses can meet different working pressures.

single relief

Only single-sided pressure forming, usually used for single-sided flat occasions, such as tank walls and transport beds, generally the thickness of the two panels is different.

The material can be stainless steel, Hastelloy, carbon steel, etc. Different materials and thicknesses can meet different working pressures.

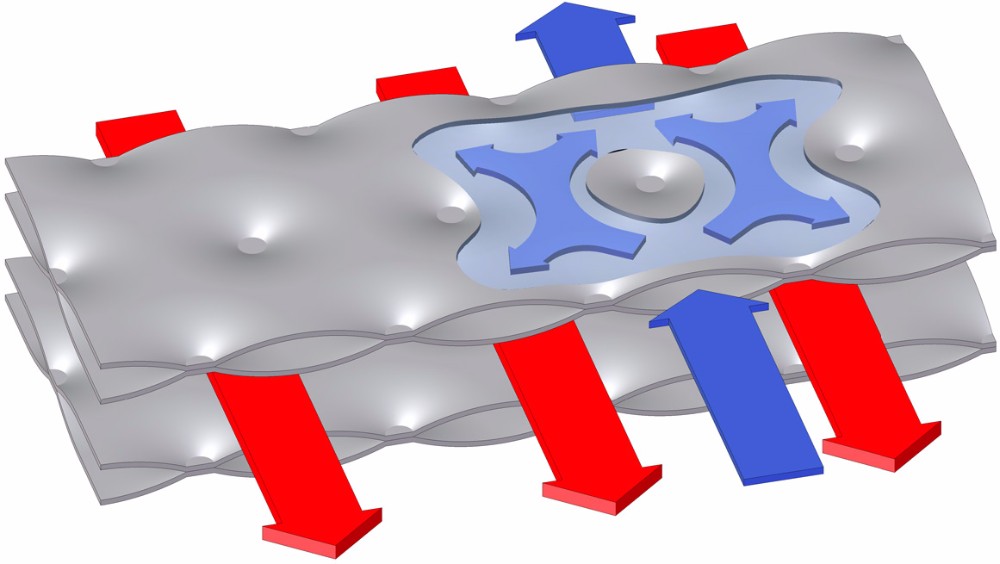

Milk Plate Heat Exchanger is a simple, effective and economical solution for maintaining temperature.Double embossed heat exchange plates are easy to install on existing tanks and equipment and are a cost-effective method of insulation.

feature

1. Easy to install on the outer walls of tanks and equipment

2. Can meet special shape and size design

3. The manufacture can meet the existing import and export pipelines, control systems and supporting structures

4. Materials are available in stainless steel and carbon steel

5. The inherent advantage of double embossing is turbulence. This design ensures that low flow velocity can also achieve high turbulence, and the heat transfer efficiency is greatly improved

6. Experiments show that the heat transfer performance of the double embossed heat transfer plate is 15% higher than that of the single embossed heat transfer plate

Most heat transfer media can be used forMilk Plate Heat Exchanger

1. Steam

2. Hot water

3. Cooling water

4. Conductive oil

5. Heat transfer fluid

6. Glycol solution

Factory view

-

Dairy SS304 500L 1000L Milk Pasteurization Plate Heat Exchanger 1000L

-

VT04 VT10 VT20 VT40 Milk pasteurization machine SS316 plate heat exchanger

-

Heat pipe heat exchanger

-

ASME industrial titanium tube heat exchanger shell tube/heat exchanger steel tube shell/aquarium chiller evaporator

-

ASME shell and tube heat exchangers, titanate pressure vessels, columns, steel reactors and complete pre-assembled units

-

Glass condenser

-

hot sale copper radiator 360 radiator small heat exchanger

-

Manufacturer 120 Copper Tube Heat Exchanger Copper Radiator

-

120/240/360/480 Copper and Brass Liquid Heat Exchangers

-

Beverage Factory Hot Sale Price Detachable Flange Plate Heat Exchanger