New semi-continuous waste tire plastic cracking plant in the United States

-

Supplier: Shangqiu Ruike Mechanical Equipment Co., Ltd. -

Region: Henan, China -

Contact: Ms Nancy Sun -

Price: $38000.00 /set -

Min. Order: 1 set

| Packaging Details: | 1*40FR+1*40HQ for 8-12Tons capacity equipment 3Tons equipment on skid, need 1*40 top open container | Reactor Life: | 5~8 years |

| Pyrolysis time: | 9-14 hours | Machine name: | Waste tire plastic cracking plant |

| After-sales service provided: | On-site installation, commissioning and training | port: | Lianyungang, Qingdao, Shanghai, Tianjin |

| Finished goods: | Tire oil, carbon black, wires, exhaust gas | strength: | 18-25KW/H |

| place of origin; place of origin: | Henan, China | Raw materials: | Waste tires, waste rubber, waste plastics |

| brand: | Rick | Heating system: | Wood, coal, natural gas, fuel oil |

| Packaging Preview: | Warranty: | 1 year | |

| Health status: | new | Working pressure: | normal |

| Supply capacity: | 20 sets per month | payment terms: | L/C,D/A,D/P,Western Union,MoneyGram |

| cooling method: | water cooling | Reactor Thickness: | 12/14/16/18mm |

| Equipment capacity: | 12 tons/day |

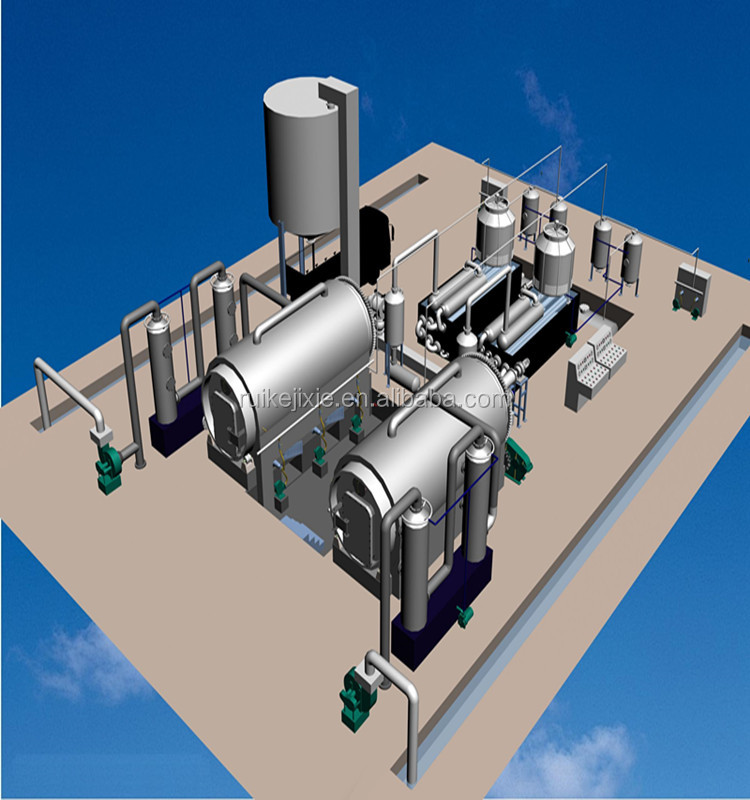

New semi-continuous waste tire plastic cracking plant in the United States

Shangqiu Ruike Machinery Equipment Co., Ltd. is located in Shangqiu Industrial Park, Henan Province, China. The entire company covers an area of about 20,000 square meters. There are more than 30 experienced installation engineers, led by a group of technical engineers. There are nearly 10 sales units selling grease, grease making machines, waste tire plastic cracking machines, and waste oil distillation machines. We have exported our machines to USA, UK, Uzbekistan, Malaysia, Indonesia, India and other countries.

Pyrolysis layout

| Model | Reactor size | capacity | strength | Covered area |

| RK-PP3 | 2100*2300*16mm | 3 tons | 16.5KW | 12*5 |

| RK-PP5 | 2200*6000*16mm | 5 tons | 18.5KW | 15*10 |

| RK-PP8 | 2600*6000*16mm | 8 tons | 22.5KW | 15*10 |

| RK-PP10 | 2600*6600*16mm | 10 tons | 25.5KW | 20*10 |

| RK-PP12 | 2800*6600*16mm | 12 tons | 30KW | 20*10 |

| RK-PP15 | 2800*7500*18mm | 15 tons | 35.5KW | 25*15 |

Project Report

Machinable raw materials:

Waste tires, waste rubber, waste plastics (PP, PE, PS, HDPE), sludge,

Fuel as heating material:

Wood, coal, briquette, natural gas, diesel, fuel oil, heavy oil

Final product output (from scrap tires)

Fuel: 40%-45%

Carbon black: 30%-35%

Exhaust gas: 3%-5%

Wire: 10%-15%

Coverage area:

Machine area: 300 square meters

Including (office, warehouse, etc.): 600 square meters

Operators per shift:

3-4 people

Income and profit analysis: (using 10 tons of waste tires as raw materials)

income:

| thing | quantity | cost/ton | total |

| waste tires | 10 tons | 100 dollars | 1,000 |

| coal | 0.8 tons | 100 dollars | $80 |

| Electricity | 20KW | 0.2$*16 | $64 |

| staff member | 4 | $30 | $120 |

| total | $1264 |

result:

| tire oil | 0.4%*10 | $600 | $2400 |

| carbon black | 0.35*10 | 50 U.S. dollars | $175 |

| metallic line | 0.15*10 | 100 dollars | $150 |

| total | $2725 | ||

| daily profit | $1461/day profit |

The main material used in the reactor: Q345R

Processing time (take 10 tons as an example)

| feeding time | Auto feeder 40 minutes / manual 2-3 hours |

| Pyrolysis time | 10-12 hours |

| cooldown | 1-2 hours with the reactor lid open |

| discharge time | Carbon Ejector 40 minutes |

| manufacturing time | 10-15 days |

| installation time | 20-30 days |

| Warranty time | 2 years |

-

Newly designed waste oil-to-diesel refinery

-

Fully Automatic Plastic Recycling Pyrolysis Diesel Tire Fuel Plant

-

Beston Group does not need to install a small pyrolysis machine for batch pyrolysis of 1-3T/D plastic tire oil sludge

-

Waste Tire Pyrolysis Diesel Plant Machine Manufacturer 5 Ton

-

Automatic control machine for biomass waste plastic tire pyrolysis machine

-

profitable small pyrolysis machine mini pryolysis plant

-

Small batch waste tire/plastic/MSW pyrolysis plant to convert solid waste into fuel oil pyrolysis machine 1-2 tons

-

New Design to Recycle Scrap Tires into Diesel with 50ppm Sulfur

-

Small integrated scrap aluminum and plastic pyrolysis plant provides fuel for machines

-

CE certified 15-50 tons automatic plastic pyrolysis plant continuous waste tire pyrolysis system

Other Products

-

$55000.00 / set

$55000.00 / set -

$38000.00 / set

$38000.00 / set -

$20500.00 / set

$20500.00 / set