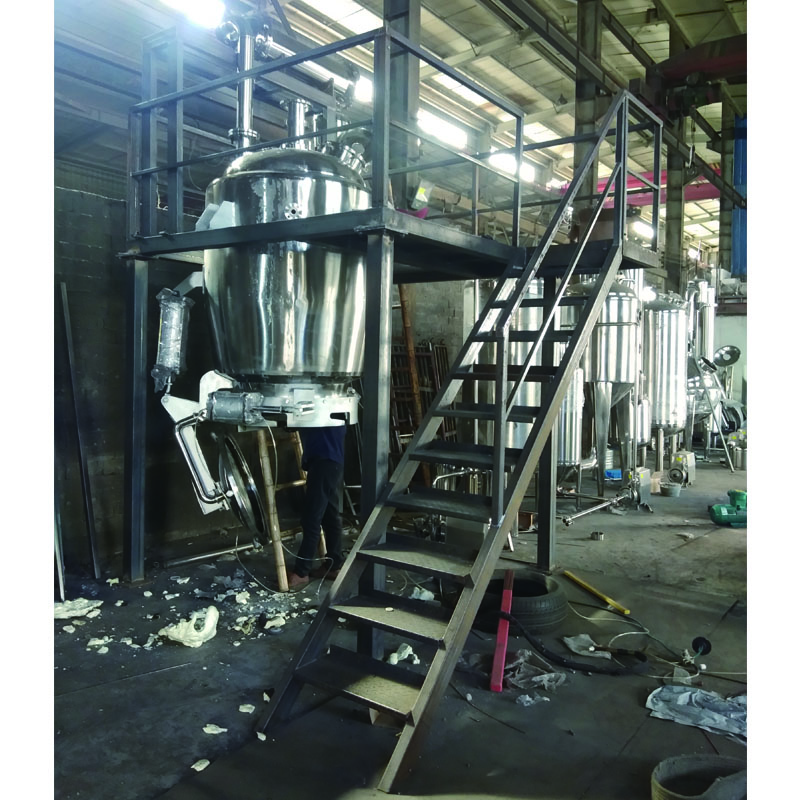

Extraction and Concentration production line

-

Supplier: Wuxi Nanwei Machinery Technology Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Taylor Yuan -

Price: $14000.00 /set -

Min. Order: 1 set

| Supply capacity: | 40 sets per month | port: | Ningbo or Shanghai |

| Warranty: | 1 year | payment terms: | L/C,Western Union,T/T |

| Mechanical test report: | if | Main selling point: | competitive price |

| Key words: | Reflux extraction device | Weight (kg): | 980 |

| place of origin; place of origin: | Zhejiang, China | Core Components Warranty: | 1 year |

| Packaging Details: | Sturdy seaworthy wooden case (extraction concentrate line) | product name: | Extraction and concentration production line |

| Showroom location: | Canada, India, Indonesia, Australia, Germany, Turkey, Uzbekistan, Italy, United Kingdom, Thailand, Vietnam | Material: | SS304/316L |

| application: | liquid | Core components: | pressure vessel |

| process: | continuously | Heat source: | steam/hot oil/hot water |

| Applicable industries: | farm | Video external inspection: | if |

| capacity: | 50-6000L | Health status: | new |

| Marketing Type: | New Products 2020 | model: | Extraction and concentration production line |

| Extraction type: | Vacuum pressure extraction |

Evaporator aromatic oil extraction and concentration unit

application

The extraction and concentration equipment is mainly used for the extraction, concentration and ointment reception in the fields of Chinese herbal medicine, animals and plants, as well as alcohol recovery and volatile oil extraction.

Advantage

1) The quality of the distilled medicine is greatly improved. The distillation cycle is short and the temperature is automatically controlled, which greatly improves the quality of the distillation material.

2) Highly automated. Temperature, pressure, flow, liquid level and concentration can be set and automatically controlled. Simple operation and stable performance. All instruments, meters, actuators and PLCs are of well-known foreign brands. Therefore, they are very reliable.

3) The inlet and outlet are completed at one time in the heating concentrator. So clumping and solidification are less likely to occur. The specific gravity of the concentrate can be 1.1-1.3. For special materials (prone to agglomerate and solidify), the natural circulation can be changed to forced circulation to meet customer requirements.

4) Using new technology and new materials, the performance of the unit is excellent. The parts in the instruments, equipment and pipelines that are in contact with the liquid medicine and solvent are all made of high-quality stainless steel.

5) There is no dead space inside. The mirror is polished. It's easy to clean. The bottom cover is sealed with air pressure to improve reliability. The still has two filter layers to prevent clogging. The distillation tank and separator are equipped with a dual-purpose defoamer.

6) The condenser adopts seamless thin tube with good heat transfer performance. The heater and industrial computer are attached to the system, making it a domestic leader in terms of performance and adaptability, reliability and stability of operation.

technical parameter

Extraction tank volume (m³) |

1 |

2 |

3 |

4 |

5 |

6 |

Concentrator evaporation (kg/h) |

50 |

100 |

200 |

300 |

500 |

600 |

Working pressure (Mpa) |

0.08~0.2 |

|||||

Use vacuum (Mpa) |

0.05~0.08 |

|||||

Extraction and concentration temperature (°c) |

70~100 |

|||||

Extraction and concentration time (hours/batch) |

4~5 |

|||||

Evaporator aromatic oil extraction and concentration unit

Evaporator aromatic oil extraction and concentration unit

Evaporator aromatic oil extraction and concentration unit

Our factory:

-

Widely used ultrasonic disperser ultrasonic crusher ultrasonic homogenizer

-

Inventory hydrocarbon extraction system machinery and equipment

-

Closed Ring Puller Set 1lb 5 Lb

-

12x4" Flat Platform Jacketed Shredder Pan

-

Stevia sugar factory sugar extraction machine in stevia sugar production line

-

Mini 1lb closed loop stainless steel extractor ring machine

-

SS304 Closed Loop Extractor 1L-20L Subcritical Extractor Closed Loop Extractor/CO2 Extractors

-

1000L stainless steel equipment for extracting coffee plants

-

304 stainless steel closed ring extrusion machine

-

5lb 10lb closed loop suction system 5lb sight glass for closed loop system

Other Products

-

$2700.00 / set

$2700.00 / set