CE energy saving fused glass machine price

-

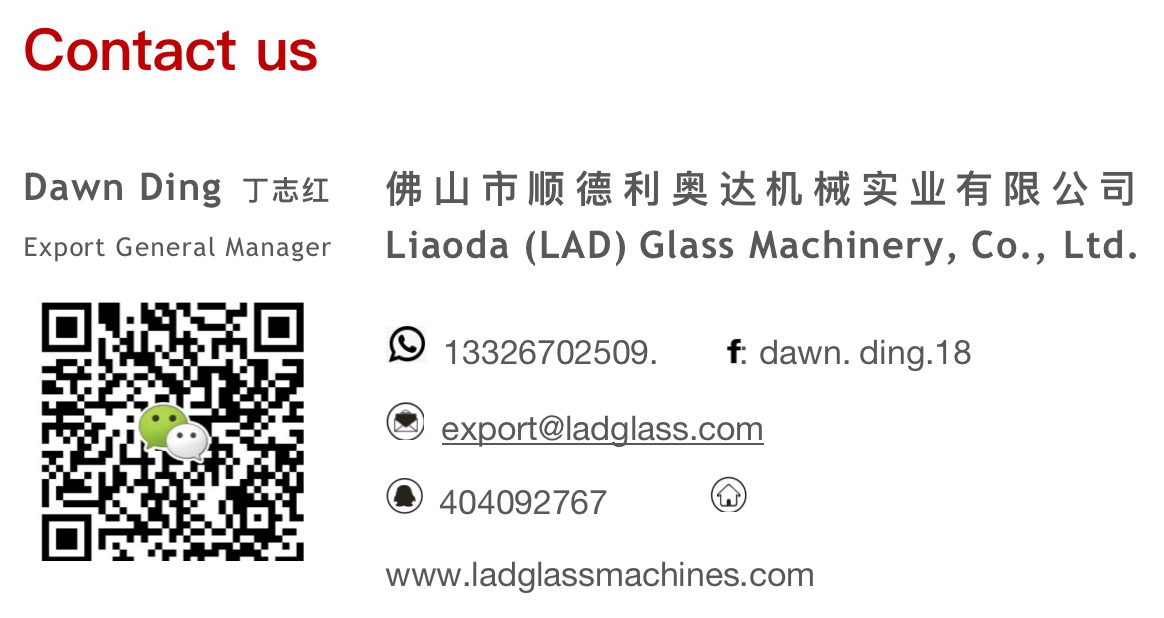

Supplier: Liaoda (LAD) Glass Machinery Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Dawn Ding -

Price: $60000.00 /set -

Min. Order: 1 set

| Production capacity: | 5mm thick glass 15-18 batches/hour | place of origin; place of origin: | Guangdong, China |

| Supply capacity: | 30 sets per year | Showroom location: | Egypt, Turkey, Saudi Arabia |

| Warranty: | 1 year | strength: | 600kW |

| glass thickness: | 4-19mm | Packaging Details: | Plastic Bubble Sheets for FCL Shipping |

| brand: | YD | Core Components Warranty: | 1 year |

| weight: | 28 kg | Applicable industries: | Hotels, building materials stores, manufacturing plants, restaurants |

| Dimensions (L*W*H): | 16.8x10x2.8m | Core components: | Motor, PLC |

| Voltage: | 220/380/415/480V, 50/60HZ | After-sales service provided: | 1 year warranty |

| Marketing Type: | normal product | Video external inspection: | if |

| Main selling point: | easy to operate | Certification: | GB15763-2005 |

| Type of machine: | Glass tempering furnace | payment terms: | L/C,Western Union,T/T |

| After Warranty Service: | On-site maintenance and repair services | Health status: | new |

| port: | Shunde, Guangdong | Mechanical test report: | if |

German Beckhoff control system high quality tempered glass machine price

household appliances Architecture/Construction furniture

glass type

- Clear float glass or flat glass

- Large pieces of colored float glass or flat glass

- Single-sided printed glass

- In-Line Low-E Glass

- Offline low-e glass (convection machine)

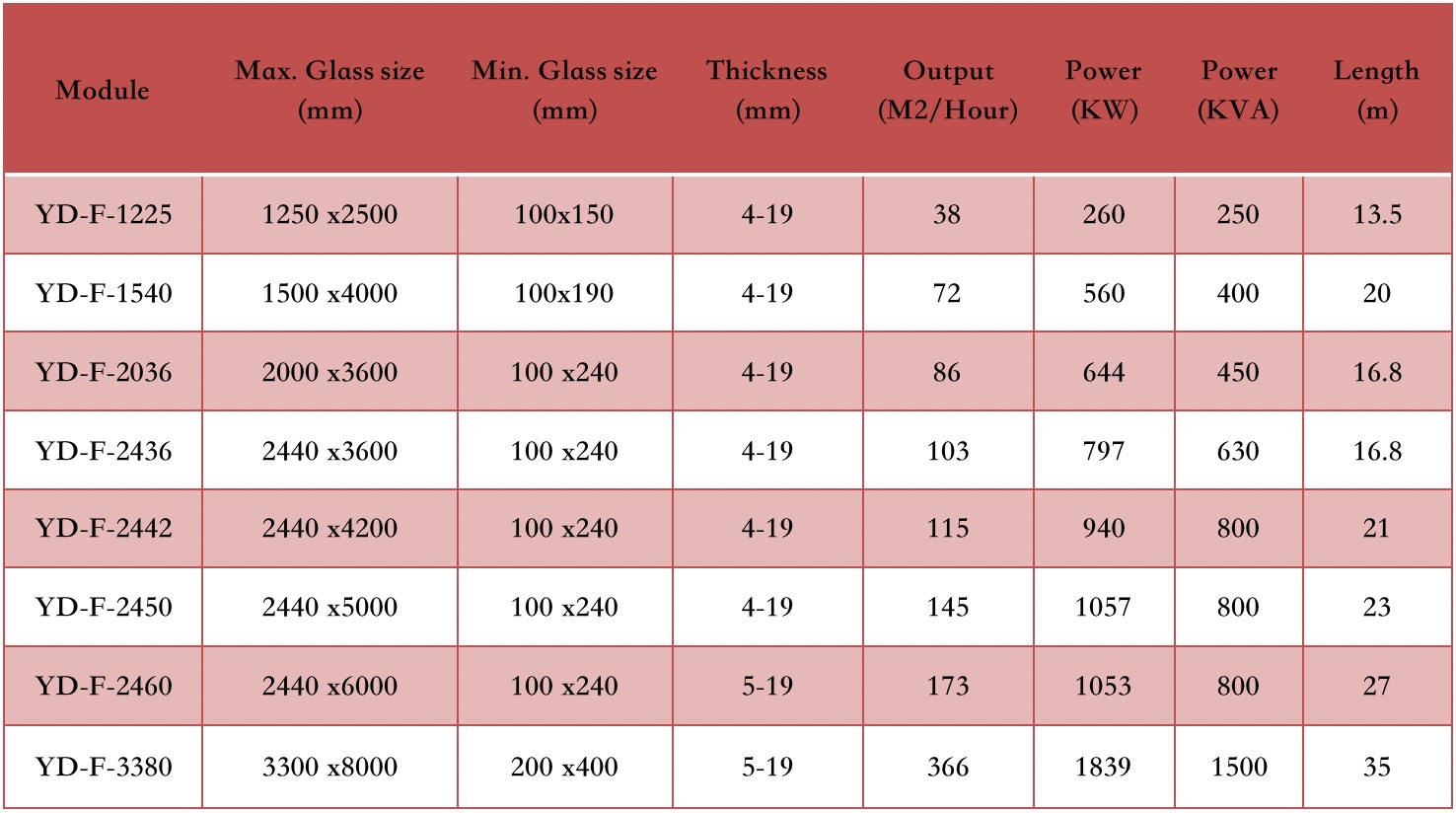

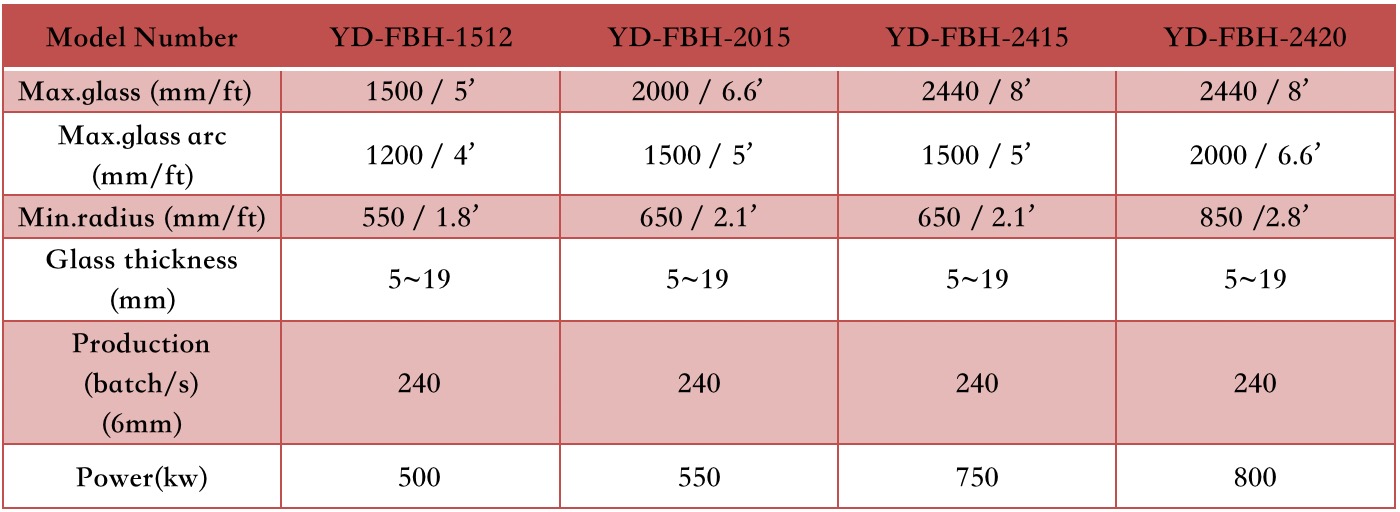

Technical Data/Flat Glass Tempering

Machine size can be designed on request!

Technical Data/Bent Glass Tempering

Tempered glass quality standard

- Products meet China's national quality standards

- Glass stress balance, particle uniformity

- All finished glass is of the same quality

- Heat resistance: in line with international standards

advantage

1. Optimum glass flatness

The descending distance of the upper and lower quenching can be controlled separately by the computer, which is convenient to adjust and control the flatness of the glass

2. Remove stress traces on tempered glass

Reasonable air hole layout and roller swing eliminate tempering stress points.

3. Advanced heating system

The specially designed heating system and intelligent power regulation make the temperature control more accurate.

4. Simple operation

The machine has a very intelligent control system. All parameters of different thicknesses and sizes can be saved on the industrial computer as recipes. The operator only needs to select one before tempering.

5. High quality parts

The machine adopts high-quality ceramic rollers, blowers, controllers, inverters, heating wires, modules, thermocouples and other electrical components with excellent performance.

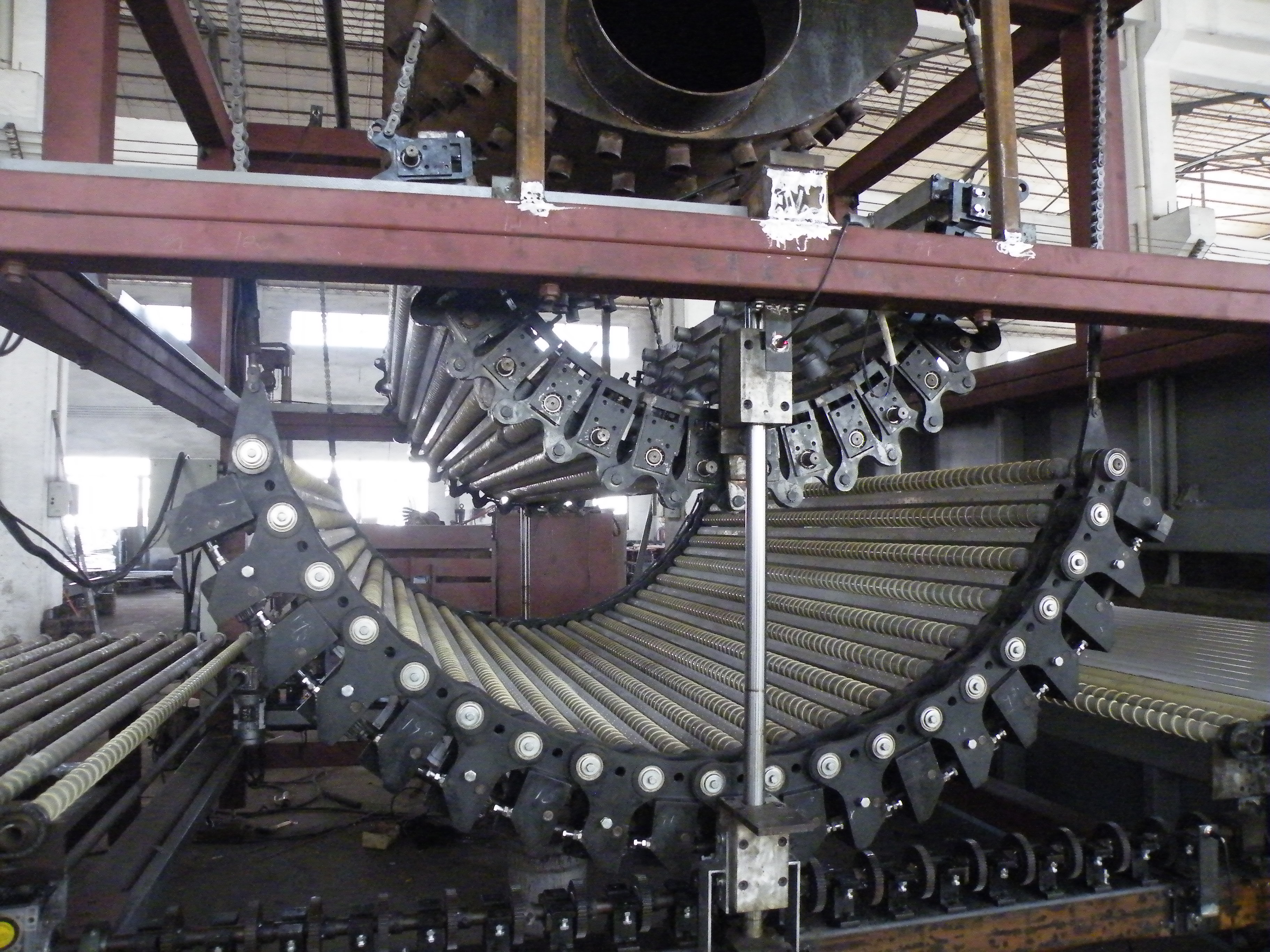

Machine in workshop production (before painting)

|

question |

Answer |

|

How to install the machine? |

We will disassemble the machine into small sections for loading into containers. We will send engineers to your factory for installation; Or, if we are unable to send an engineer due to Covid-19 or other issues, we will guide your engineer how to install it. Or we bring in engineers from other countries to assist with machine installation. |

|

Is the machine difficult to operate? |

Receipts for different glass will be set on the control system. Receipts of different thicknesses and glass process types can be selected, and fine-tuned according to glass size and quality. |

|

How to send? Can a shipment be arranged? |

We can recommend our freight forwarder to you. You can contact them to arrange shipping. |

|

Our voltage is 400V/440V/600V, can you do it? |

Yes, we can manufacture machines according to customer's requirements |

|

Can you provide me if I need to order more spare parts? |

Yes, we can provide spare parts. Some spare parts can be prepared with the machine later to save on shipping costs. |

|

How do I get an assistant if the machine doesn't work? |

You can contact our sales manager for service. We will reply as soon as possible, most of the time within 12 hours. |

|

What are the payment terms? |

30% of the total amount as down payment 67% of total payment before delivery Balance after debugging |

|

How long is the delivery time? |

75-90 days |

|

Warranty |

1 year |

|

What is weight and how much CBM does a machine have? |

depending on machine size |

|

What is the import duty on the machine? |

Please check the HS code from your government website for tax rates. HS Code: 8475291900 |

|

How many sets can one container hold? |

depending on machine size |

-

2436 Full Convection Flat Glass Tempering Furnace

-

aluminum cutting machine for window making aluminum cutting for door and window making machine

-

Portable Glass Edger

-

Glass Air Table

-

Glass Air Cushion Table

-

China fast light glass edging machine

-

Portable glass beveling edge grinding edge processing machinery linear glass mirror edge polishing machine

-

Turnkey project of frit glass melting furnace production line

-

Glass Processing Equipment Linear Glass Bevel Polishing Machine

-

Factory Promotion 2022!!! Glass washing heating drying machine for the production of 1600 mm insulating glass

Other Products

-

$9400.00 / set

$9400.00 / set -

$7000.00 / set

$7000.00 / set