50-220L steel drum/barrel making machine

-

Supplier: Taian Topsun Import And Export Co., Ltd. -

Region: Shandong, China -

Contact: Mr Qicai Song -

Price: $3000.00 /set -

Min. Order: 1 set

| weight: | 5000 kg | Materials used for packaging: | Metal |

| Warranty: | 1 year | place of origin; place of origin: | China |

| Supply capacity: | 30 sets per month | Dimensions (L*W*H): | L1340*W1580*H1950mm |

| output: | 3-4 drums/minute | Driver type: | electrical |

| After-sales service provided: | Online support, video technical support, on-site installation and commissioning training, on-site maintenance services, on-site service by overseas engineers | product name: | China 55 gallon steel drum manufacturer |

| Voltage: | 220V/380V | Packaging Details: | 50-220L steel drum/barrel making machine standard seaworthy packaging |

| Health status: | new | Certification: | CE certification |

| brand: | 55 gallon steel drum | type: | Packaging line |

| application: | Mechanical hardware | type of packaging: | bucket |

| payment terms: | L/C, T/T, Western Union | port: | Main ports in China for 50-220L steel drum barrel making machine |

| Automatic level: | semi-automatic | Key words: | 50-220L steel drum barrel making machine |

China 55 gallon steel drum manufacturer rolling machine

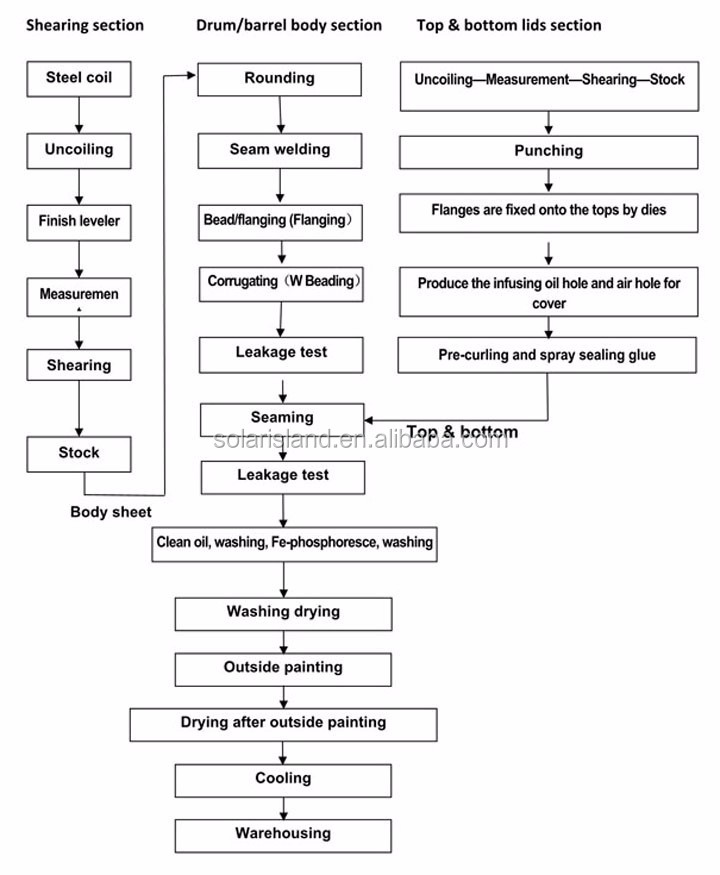

A. Rounding machine:

The spheroidizing machine is a three-roller type, driven by a motor, with an adjustable radius, equipped with a special guide plate to minimize the edges at both ends of the steel plate. Unit power: 2.2KW;

Auto Welding Machine 55 Gallon Steel Drum Manufacturers in China:

B. Automatic welding machine:

Connect the circular cylinder body along the direction of the cylinder body, weld by seam welding machine, and operate manually. Power: 150KVA;

Extrusion Flange And Crimping Machine 55 Gallon Steel Drum Manufacturer In China:

This machine puts the barrel body into the forming template, moves back and forth to directly form the flanging, and simultaneously presses the ribs. High flanging precision, higher work efficiency, suitable for cold-rolled steel sheet, PLC control, hydraulic drive. Unit power: 22KW.

China Corrugated 55 Gallon Steel Drum Manufacturer

This machine puts the barrel body into the forming template, moves back and forth, and directly forms the flange; at the same time, it performs ribbing. High flanging precision, higher work efficiency, suitable for cold-rolled steel sheet, PLC control, hydraulic drive. Unit power: 22KW.

Sealer:

Manually put the top and bottom of the barrel on the loading rack, and the barrel body is automatically loaded and pressed together. Double motors, two spindles running, which is a new structure in this field, drive the sewing machine.

The rollers of the sewing machine are driven by hydraulic pressure, easy to adjust, controlled by PLC, and the power of the single machine is 41KW.

Leakage test machine:

Horizontal test, air pressure 0.03Mpa. Manually spray soapy water and manually test for leaks. There are two types of leak testing machines, one is PLC controlled, hydraulically driven, and the other is simple, normally controlled, pneumatic testing machine

Steel drum production line cleaning line

(1) Rain channel: see the washing equipment process flow table for details;

(2) Washing and transportation

Type: The conveying roller advances and rotates on its own

Speed: 0.5-4m/min.

Motor: electric, stepless speed regulation;

Material: chain --- 304 stainless steel or other;

Axle --- 2Cr13 stainless steel;

China 55 gallon steel drum manufacturers coating equipment:

(1) Paint booth

(2) Coating type: barrel vertical;

(3) Paint color and ribbon:

A. Color: The lid, bottom, and both ends of the barrel are the same color; the middle of the drum body is the same color.

B. Ribbon: The connection surface of the two colors is clean, the mixing surface is less than ±1mm, and the paint fog is allowed, but it cannot be seen beyond 1000mm.

(4) PLC control box: 1 set; (control painting and transportation)

Steel drum production line drying line

Heating method: oil heating;

Heat engine unit: 2 sets (the main components are made in Italy);

Fuel consumption: 80L/h (2 units) Max;

Working temperature: room temperature to 200°C, and can be adjusted continuously;

Temperature control accuracy: ±5°C (action accuracy);

Heating time: ≤20min. (at room temperature 20°C)

Insulation performance: when the channel is 200°C, the surface temperature rise is less than 10°C (locally less than 15°C);

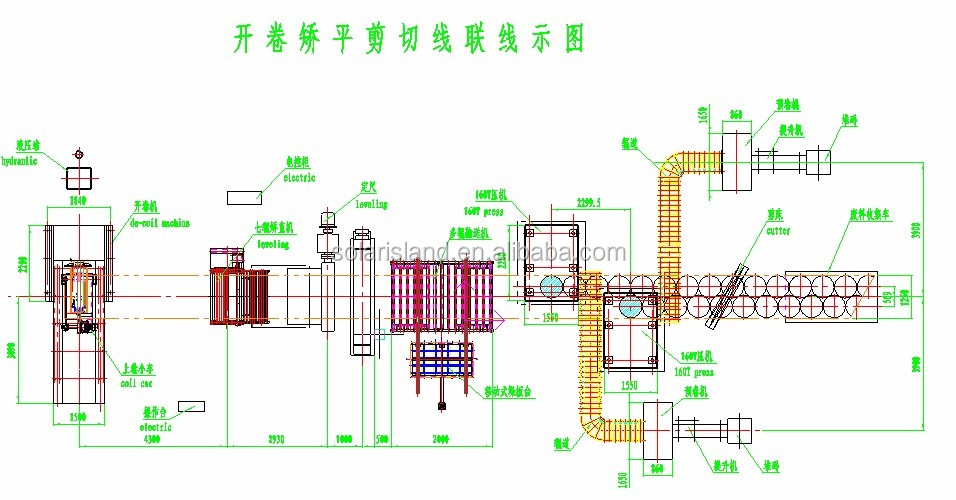

Steel drum end cover chassis production line

A. Cutting steel plate size: width 600-1320mm; thickness 0.6-1.4mm;

B. Production capacity: cutting 11 times/minute; maximum. Cutting speed 40-50m/min;

C. The total weight of the equipment: about 55 tons;

D. The total power of the equipment: 45KW;

E. Production level: cutting accuracy

Length: Tolerance 0.5mm; Diagonal: Tolerance 1mm

Steel drum production line

Q: How do you guarantee the quality?

A: We have a strong design and technical team, our team ensures each stage of the production process, and our QC also checks each procedure. We can design and manufacture according to your requirements.

Q: How can I get an accurate quotation?

A: Please provide us the details of the workpiece, such as drawings or daily output

Q: How much is the shipping cost from China to your country?

A: We can send the machine to your port by sea. Customer appoints forwarder or negotiable shipping method.

Q: Payment terms, MOQ, warranty, FOB...

A: Payment terms: 30% down payment on order

Delivery time: 3 months after receiving the formal order

Warranty: 12 months after delivery. We provide online services 24 hours a day, Skype, Email, etc., you can contact us at any time.

-

Metal can end making machine/can end production line

-

High-speed automatic carton cartoon box folding gluing machine corrugated carton carton gluing machine

-

Fully automatic high-speed vertical carton packaging food pizza bottle soap gloves plastic carton box packing machine

-

Carton Liner Bag in Box Line for Packaging Margarine Butter Semi-Liquids

-

Fully-automatic Bag in Box Filling Packaging Line

-

A full set of automatic filling and sealing pure drinking sachet water packaging line

-

Y-Pack buy kn94 n95 facial mask carton packaging machinery automatic cartoning machine cartoning machine

-

Fully automatic single-sided e-groove corrugated cardboard carton carton product making machine

-

Best Selling Automatic Premade Bags Automatic Filling Sealing Packaging Machine

-

Fully Automatic Hot Selling Robot Carton Pallet Bag Palletizer, Shrink Bottle Palletizer