Walmart thank you plastic pe ldpe hdpe automatic double line degradable shopping bag bag making machine

-

Supplier: Shantou Longhua Packing Machinery Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Alice Xie -

Price: $6500.00 /set -

Min. Order: 1 set

| OEM service: | supply | Supply capacity: | 400 sets per year |

| Conveyor assembly: | Conveyor assembly | feature: | Inverter and back screen photonic sensor |

| State of health: | new | Core component warranty: | 1 year |

| Function: | T-shirt bag making machine | Warranty: | one year |

| Maximum speed: | 320 pieces/min | application: | Cold Cut Bottom Seal Bag - Shirt Bag |

| brand: | Longhua Machinery | Package preview: | |

| Material: | plastic | Video shipment inspection: | if |

| servo motor: | Japan | port: | Shantou |

| weight: | 750 kg | Package width: | 120-880mm |

| Mechanical test report: | not available | Showroom location: | not any |

| Dimensions (L*W*H): | 3.0x1.5x1.4m | Applicable industries: | Manufacturing plants, food and beverage plants, retail |

| model: | SDB-BG | After-sales service: | 1 year warranty |

| Type of machine: | Making Machine | Voltage: | Three-phase 380V |

| place of origin; place of origin: | Guangdong, China | Marketing Type: | New Products 2020 |

| options: | Air shaft, magnetic powder tension, EPC, punch | payment terms: | L/C, T/T |

| Core components: | Motors, pressure vessels, PLCs, servo motors and drives | Packaging Details: | Wooden pallets, wooden boxes. |

| Computerized: | yes | product name: | One Layer Two Lines Heat Sealing Hot Cut T-shirt Bag Making Machine |

| Package type: | vest bag | Main selling points: | high productivity |

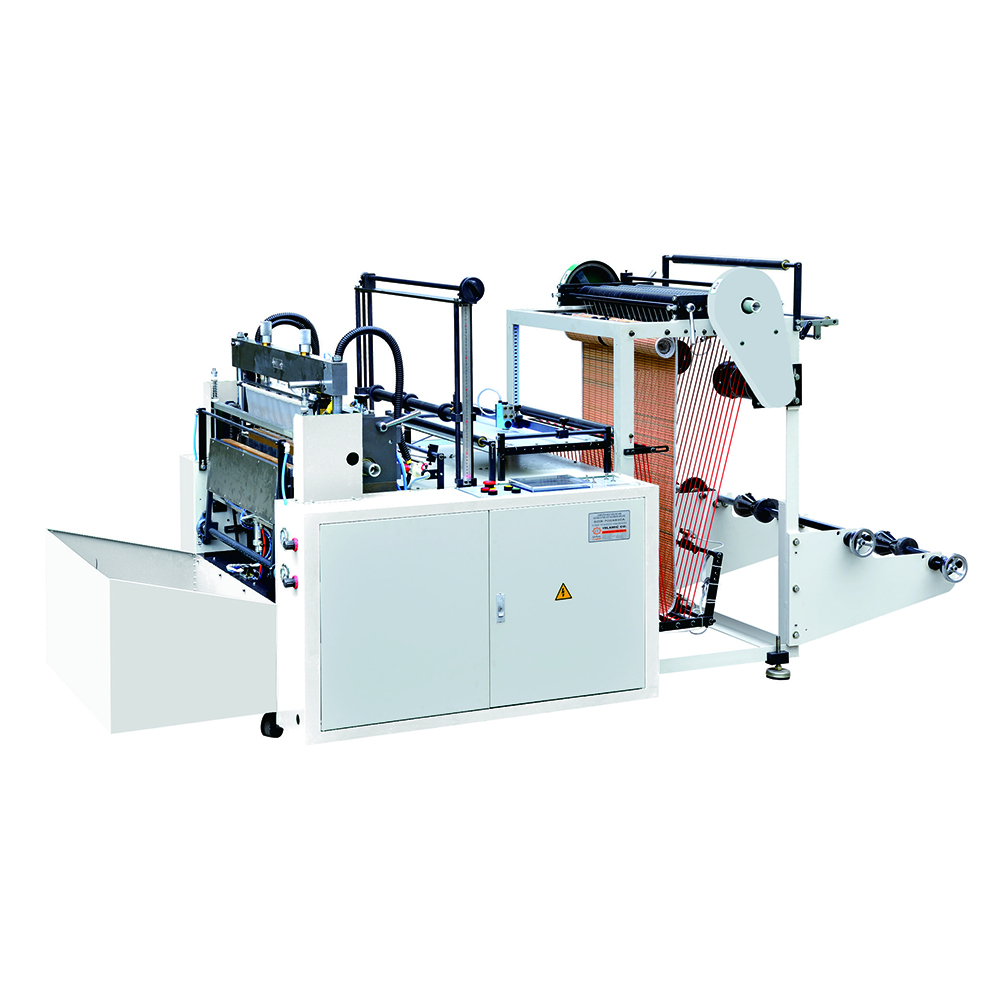

One-layer two-line heat-sealing hot-cut vest bag bag making machine SDB-BG

1. Used to make 1-layer 2-line heat-sealed hot-cut HDPE/LDPE vest bag.

2. This machine adopts Ormon PLC and touch screen, with clear display and convenient operation.

3. The rear feeding adopts AC motor with 2 wires and photoelectric automatic control, which can automatically adapt to the production speed.

4. Newly designed seal structure, turn the seal upside down for easy cleaning. This new structure is safer and more reliable.

5. It has the functions of paper jam detection, feeding error detection, printing mark detection, automatic stop and alarm.

options:

1. Gas well

2. Magnetic particle tension

3. EPC Contracting

4. Hole punch

|

Specification |

SDB-B-500G |

SDB-B-700G |

SDB-B-900G |

|

bag width |

120-480mm |

130-680mm | 150-880mm |

|

bag length |

250-800mm | 300-800mm | 300-1000mm |

|

machine speed |

50-160 pcs/min | 50-150 pcs/min | 50-140 pcs/min |

|

bag thickness |

0.025-0.12mm | 0.025-0.12mm | 0.025-0.12mm |

| Feeding speed | 50m/min | 50m/min | 50m/min |

| required power | 6.5kw | 8 kW | 10 kW |

| northwest |

750 kg |

900 kg |

1050 kg |

| Machine size |

3.0x1.1x1.4 meters |

3.0x1.3x1.4m |

3.0x1.3x1.4m |

|

main feature |

brand |

nation |

|

touch screen |

surface |

Japan |

|

Programmable Controllers |

Omron | Japan |

|

servo motor |

Panasonic/Yaskawa | Japan |

|

engine

|

seam | Germany |

| dawn | Taiwan | |

|

inverter |

Fuji/Mitsubishi | Japan |

|

marker sensor |

sick | Germany |

| data logic | Italy | |

|

solid state radar |

Qantas | United States |

|

Pneumatic Components |

Festo | Germany |

| SMC | Japan |

-

Semi-automatic plastic film vest shopping bag forming machine vest bag plastic bag production line

-

High Quality Plastic Fully Automatic Irregular Shaped PP Bag Making Machine Die Cutting Custom Shape Polyester Film Bag Machine

-

High Speed Food Paper Bag Making Machine Price List

-

Wholesale Eco-Friendly Polypropylene PP Spunbond Non Woven Fabric Bag Making Machine

-

Second-hand eight-side-seal bag-making machine Shanghai Kunrun brand 600-type 8-side-seal bag-making machine

-

2022 New Double Layer T-shirt Shopping Bag Making Machine With Four Lines Biodegradable PE Plastic

-

Four line bottom sealing bag cutting machine

-

Heat Sealing Cold Cutting Plastic Garbage Bag Making Machine

-

T-shirt plastic bag punching machine

-

High-speed (400-600 pcs/min) automatic four-row plastic shopping bag vest bag making machine