Biomass wood charcoal manufacturing carbonization machine plant

-

Supplier: Beston (Henan) Machinery Co., Ltd. -

Region: Henan, China -

Contact: Mr Kevin Zhu -

Price: $98000.00 /set -

Min. Order: 1 set

| After-sales Service Provided: | Field installation, commissioning and training; | Place of Origin: | Henan China (Mainland); |

| Advantage: | Continuous Working Environment Friendly; | Applicable Industries: | Manufacturing Plant,Biomass carbonization; |

| Weight: | 3500kg; | Name: | Biomass wood charcoal manufacturing carbonization machine plant; |

| Rotary speed of furnace: | 17 turn/min; | Effective Volume: | 12600*2540*400 mm; |

| Structure: | Horizontal & Rotary; | Supply Ability: | 5 Set/Sets per Month; |

| Brand Name: | Beston; | Voltage: | 380V; |

| Payment Terms: | L/C,T/T,Western Union,MoneyGram,Trade Assurance; | Condition: | New; |

| Capacity: | 2Ton-3 Ton KG/H; | Certification: | ISO CE; |

| Power(W): | 45-100 KW/H; | Packaging Detail: | 1.Equipment body: plastic film. 2.Accessories: standard export wooden cases. 3.We can do as your requirement.; |

| Warranty: | 1 Year; | Fuel: | Charcoal, Wood, diesel; |

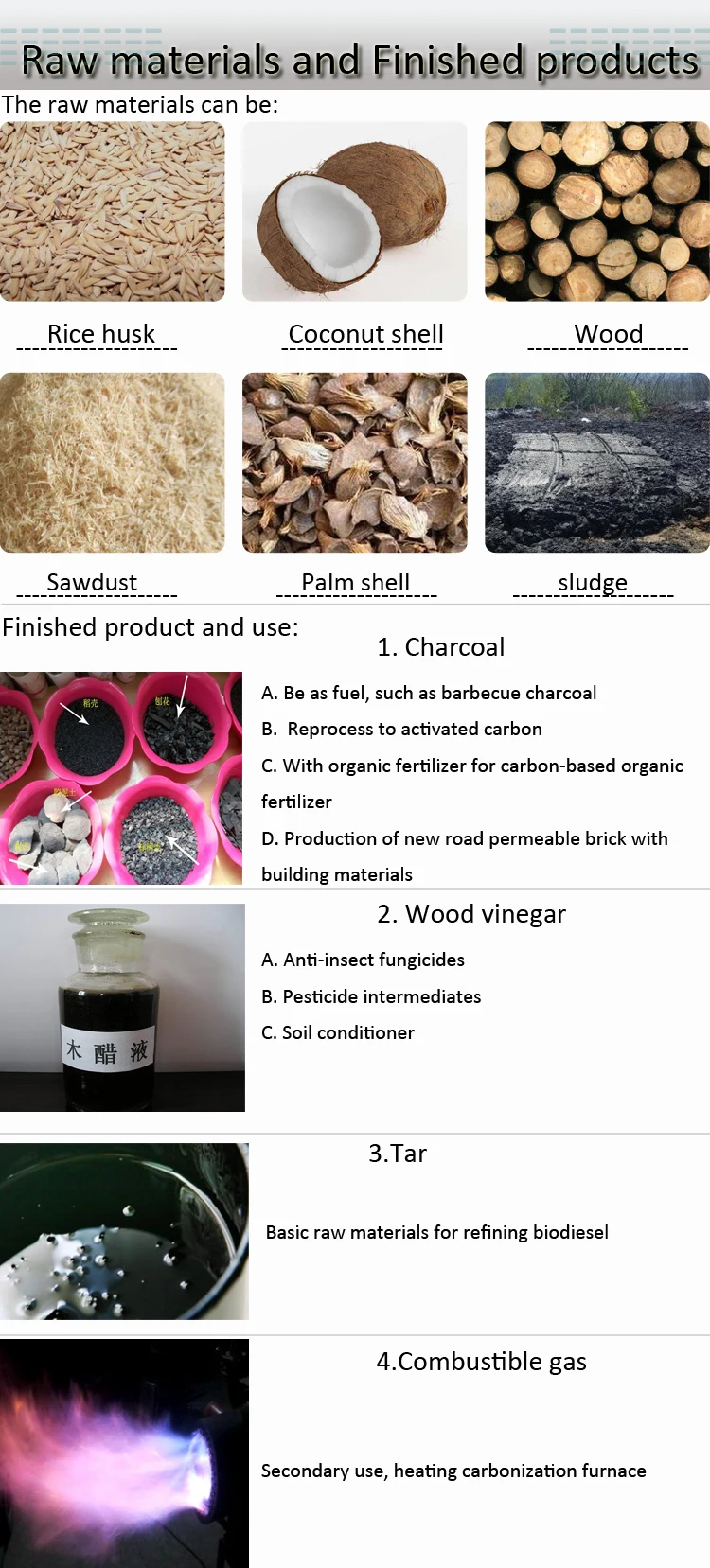

| Color: | Customer's Request; | Raw material: | Sawdust ,Coconut shell .Wood ,Rice husk and other biomass material; |

| Dimension(L*W*H): | 12600*2540*400 mm; | Port: | Lianyungang; |

| Operating Pressure: | Constant Pressure; | Service: | 24 hours online; |

Biomass wood charcoal manufacturing carbonization machine plant

Beston Biomass carbonization plant is a system that can process the sawdust ,cocount ,wood ,rice husk and other biomass material /waste sludge into some profitable products like charcoal,wood vinegar,tar,combustible gas ,and can make profit for you.

Model | BST-05 | BST-10 | BST-20 | BST-30 |

Raw materials | Sawdust ,Coconut shell,Wood ,Rice husk and other materials /waste sludge | |||

Structure | Horizontal | |||

Capacity | 300-800 KG | 1-2 TON | 2-3 TON | 3-5 TON |

Rotary speed of furnace | 17 turn/min | |||

Power | 45 KW/H | 60 KW/H | 75 KW/H | 100 KW/H |

Host size | 8060*1600* 2900mm | 10600*2100*3350mm | 12600*2540* 4000mm | 13100*2990* 4300mm |

1. Reactor: stainless steel 310s, thermostability.

2. Large processing capacity, fully continuious, strong sense of science and technology.

3.De-dusting system, smoke emission meet EU standard.

4. Automatic sealed discharging system, no dust flying.

5. Combustible gas recycled, save fuel.

Packaging:

1.Equipment body: plastic film.

2.Accessories: standard export wooden cases.

3.We can do as your requirement.

Beston (Henan) Machinery Co., Ltd was founded in 1998, which is an innovative and high -tech enterprise, incorporating research, manufacture, sales, service, import and export. Specializing in the production of recycling production line, solid waste separation, indluding waste tyer, rubber and plastic pyrolysis plant, Oil distillation plant, Carbon black deep processing plant. Through sophisticated organic polymer pyrolysisi technology and environmental and production equipment. Since the factory was founded, it equips with advanced producution technology, frist -class quality products and personalized service philosophy, after 18 years of unremitting efforts, we have developed into the industry leader. we are committed to environmnetal protection industries, products certified by CE, ISO, etc.

.

Q1.What are the requirements for feed size and moisture?

The normal feed size is below 2 cm and the current maximum feed size is 5 cm (peach nucleus). In general, a crusher is required for more than 2 cm.The normal feed moisture of the carbonizer is less than 15%.

Q2.Material carbonization temperature:

Temperature control by fan.Biomass is generally 380 degrees Celsius - 450 degrees Celsius,The carbonization temperature of the sludge is higher than 500-650 degrees,The carbonization temperature of the garbage is about 600--850 degrees

Q3. About dust removal and exhaust emissions:

All gases are led by the fan. (The fan is frequency-converted, and the air volume can be adjusted by the PLC according to the actual amount of gas generated to achieve the best effect.) After the dust collector is used, the smoke tower is sprayed 5-8 steps and then drained. The specific exhaust gas treatment situation gives different configurations to meet customer requirements based on customer requirements.

Q4.Questions about the rate of charcoal:

Answer: Take the coconut shell shredded by sawdust and rice husk as an example:

For every ton of water containing less than 10%, the finished carbon 280KG----310KG can be obtained. After removing water, it is basically maintained at 3:1.

Q5.Equipment safety measures:

1. When the equipment is working, the equipment is micro-negative pressure (the pressure gauge shows 8mm negligible). The main furnace end is equipped with explosion-proof holes (to prevent excessive pressure inside the equipment)

2. PLC electric cabinet has alarm device, there will be alarm display and alarm for partial failure of electric appliance

3. Explosion-proof water seal at the gas pipeline (to prevent abnormal gas pressure in the equipment)

4. All pipeline gas directions are led by the fan (the fan is frequency conversion), and the pipeline will be displayed on the PLC when it is blocked.

24-hour online ,if you have other questions about this pyrolysis plant and our company ,

please contact us !

-

Low Price Carbonization Furnace Charcoal Making Machine

-

charcoal forming machine charcoal forming machine charcoal forming machine

-

Charcoal production equipment cost investment small economical small carbonization furnace smokeless carbonization furnace

-

Multifunctional carbonization furnace charcoal machine

-

Coco coconut shell charcoal carbonization furnace machine

-

Factory direct supply charcoal kiln wood chip carbonization machine carbonization furnace

-

China large capacity industrial smokeless wood chip carbonization furnace kiln

-

Large Capacity Log Biochar BBQ Charcoal Making Machine Price

-

Biomass carbonizer rotary kiln

-

Activated Carbon Manufacturing Factory Charcoal Making Machine Activated Carbonization Furnace For Sale