100% original cnc blade high quality alloy blade

-

Supplier: Zigong Dingli Alloy Material Co., Ltd. -

Region: Sichuan, China -

Contact: Ms Hua Li -

Price: $1.50 / 1 - 99 pieces

$0.70 / >=100 pieces -

Min. Order: 1 piece

| usage: | External turning tool | Supply capacity: | 100000 pieces per month |

| port: | Shenzhen, Guangzhou, Ningbo, Chongqing, etc. | Package preview: | |

| pay: | TT\ Paypal\Escrow\L\Visa etc. | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram, VISA |

| model: | DL-5 | coating: | chemical vapor deposition, physical vapor deposition |

| MOQ: | 10 | color: | yellow, purple, black |

| Origin: | Sichuan, China | pack: | 10pcs/plastic box |

| Material: | 100% virgin tungsten carbide | Customization support: | OEM production |

| Artifacts: | steel, stainless steel, cast iron | grade: | TBC2005, TBC2025, TBG2215, TBG2225 |

| application: | CNC machine tool | hardness: | HRA89~HRA93.5 |

| type: | Turning Inserts | Packaging Details: | Wooden case/carton/iron case and other plastic bags or boxes. |

| product name: | Carbide Lathe Tool | brand: | Dingli |

Carbide InsertsReplaceable and typically used for machining steel, cast iron, superalloys and non-ferrous materials. Carbide inserts allow for faster machining and leave a better finish on metal parts. Carbide inserts can withstand higher temperatures than HSS tools.

- Carbide grades:

|

grade |

ISO code |

chemical composition (%) |

Granularity um |

physical and mechanical properties (≥) |

||||

|

bathroom |

limited company |

others |

Density g/cm3 |

Hardness (HRA) |

TRS Newton/mm2 |

|||

|

D10UF |

K05-K15 |

93 |

6 |

1 |

0.6 |

14.70 |

93.0 |

2600 |

|

D30UF |

K20-K30 |

89 |

10 |

1 |

0.6 |

14.50 |

92.0 |

3800 |

|

D30SF |

K20-K30 |

89 |

10 |

1 |

0.5 |

14.40 |

92.5 |

4000 |

|

D40SF |

K40 |

87 |

12 |

1 |

0.4 |

14.30 |

92.5 |

4200 |

|

DB10X |

K20-K30 |

89 |

10 |

1 |

0.6 |

14.50 |

91.5 |

3800 |

|

DP12X |

K30-K40 |

87 |

12 |

1 |

0.6 |

14.15 |

91.0 |

3300 |

|

DP13X |

K40 |

86 |

13 |

1 |

0.8 |

14.10 |

90.5 |

4400 |

|

YG6 |

K05-K10 |

93 |

6 |

0 |

1.2 |

14.95 |

91.0 |

2600 |

|

YG6X |

K10 |

93 |

6 |

0 |

1.0 |

14.95 |

92.0 |

2500 |

|

YG8 |

K20-K30 |

92 |

8 |

0 |

1.2 |

14.70 |

90.0 |

2800 |

|

YG10X |

K30-K40 |

89 |

10 |

1 |

0.8 |

14.50 |

91.0 |

3500 |

|

YG15 |

K40 |

85 |

15 |

0 |

1.2 |

14:00 |

87.5 |

4500 |

|

YG25 |

-- |

75 |

25 |

0 |

1.2 |

13.15 |

82.5 |

4800 |

Zigong Dingli Alloy Co., Ltd. is located in the new industrial parkZigong, Sichuan, China's famous cemented carbide production base. thisfactoryMainly engaged in the production and development of various cemented carbide products, such asRod tubes, tungsten carbide rods and flat bars.In China, our goal is to become a manufacturing center base for extruded bars, carbide boring bars, standard tools, non-standard tools and hard machining tools, and to establish a good and healthy corporate image in the industry.

The main production equipment

Currently the company can. In general, our products can be used in the manufacture of moulds, electronic products, automobile engines and accessories, military equipment, petroleum machinery, machinery manufacturing, etc. We have stable clients such asUSA, Russia, Indonesia, Korea, Japan, Australiaetc.

Testing Machine:

Our company was established in July 2011. The quality and reputation of the company's products have reached the upper-middle level in China, second only to several most competitive cemented carbide companies. We continuously improve technology and introduce advanced equipment, which has greatly improved the professionalism and production scale.

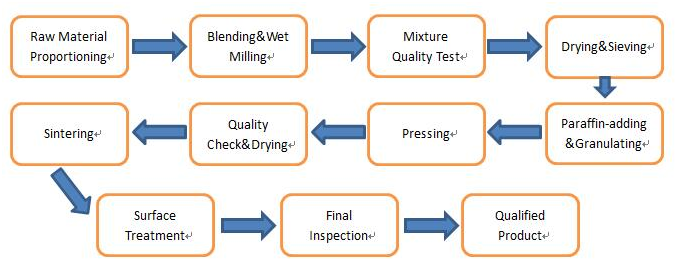

Production flow chart:

Package

1>Put the goods packed in plastic bags or plastic boxes into wooden boxes/cartons/iron boxes, etc.

2>Other packing will be accepted according to your needs.

FAQ

Q1: How long is your lead time?

A1: It depends on the specific situation. However, it may take 10 to 15 days on average.

Q2: Do you provide samples?

A2: Yes, we do provide samples. However, buyers need to pay for shipping. Also, whether the samples are free or not depends on the quantity you buy.

Q3: How do you pack the products?

A3: Generally, we use wood, plastic or carton. We also put some soft material inside to prevent possible damage to the product.

Q4: How much advance payment do I need to pay?

A4: If the product you purchased is in stock, you need to pay the full amount; if the product is out of stock, you need to pay about 50% of the full payment, and then we will start the production process. However, you still need to pay the remaining cost before we deliver the product.

Q5: What kind of payment methods do you accept?

A5: In addition to the payment methods shown above, you can also discuss with us which payment method you would like to adopt.

If you have any other questions, please contact us.

-

High Quality and Good Price 100% Original JDMT070208R JDMT070204R Carbide Inserts High Feed Milling Cutter JDMT

-

BOMI BMA-24 Wholesale Custom High Speed Steel Aircraft Extension Rod Extra Long Drill Bit Set

-

CNC cutting blade blade seat NCIH DGFH SPB SMGB 26-2 3 4 5 32-2 3 4 5 6 single head double head

-

ZCC.CT CNC turning tool carbide blade APMT160408PDER YBG202/YBG205/YBG302/YBD152 CNC lathe steel cutting tool

-

ZCC-CT milling insert zcc tool zcc ct carbide insert tool CCMT09T304-HM YBD152

-

Fengyi customized for colinet external API support insertion tubing thread insertion tool

-

KNUX rotary insert

-

Grooving blade PENTA 24N oblique blade series five-pointed star overlord groove cutting lathe tool carbide blade s

-

Manufacturer Tungsten Carbide Insert Spacer Carbide Turning Tool Holder

-

High-quality CNC machine tool holder outer circle turning tool

Other Products

-

$21.00 - $23.00 / piece

$21.00 - $23.00 / piece -

$23.00 / piece

$23.00 / piece -

$0.50 - $10.00 / piece

$0.50 - $10.00 / piece -

$10.00 / piece

$10.00 / piece -

$1.50 / piece

$1.50 / piece -

$1.20 - $1.50 / piece

$1.20 - $1.50 / piece -

$100.00 - $104.50 / piece

$100.00 - $104.50 / piece -

$3.92 / piece

$3.92 / piece -

$1.20 / piece

$1.20 / piece -

$3.00 / piece

$3.00 / piece