PET Plastic Belt Production LinePET Packing Belt Equipment Belt Making Machine

-

Supplier: Suzhou Poks Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Lucy Fan -

Price: $10000.00 /set -

Min. Order: 1 set

| Automatic level: | Automatic pet belt production line | Certification: | ISO, European Union |

| Pet carrier production line length: | 35 meters | Application fields: | Pet belt production line |

| Warranty: | 1 year | Plastic processing: | pets, pets |

| brand: | bosu | Product Category: | PET/PP packing tape extrusion line packing tape making machine |

| Screw speed (rpm): | 57 turns | Belt width of pet sling production line: | 9-25mm |

| port: | Shanghai brings production line for pets | Health status: | new |

| Inverter: | ABB brand | Screw material: | 38CrMoALA |

| Mechanical test report: | if | Screw design: | single screw |

| application: | Pet belt production line | Showroom location: | Egypt, Italy, Peru, Indonesia, Pakistan, India, Mexico, Russia, Morocco |

| Power (kW): | Post-90s | payment terms: | L/C, Western Union, T/T |

| Voltage: | 380V | Dimensions (L*W*H): | by capacity |

| Packaging Details: | Seaworty packing for PET plastic belt Production Line | weight: | 8000 kg |

| Marketing Type: | New Products 2020 | Pet carrier production line capacity: | 50-200kg/hour |

| Core component warranty: | 1 year | Contactor: | Siemens |

| Core components: | Bearings, motors, pumps, PLCs, others, pressure vessels, gearboxes, screws | Screw diameter (mm): | 90 mm |

| Main selling points: | automatic | Supply capacity: | one per month |

| Origin: | Jiangsu, China | Applicable industries: | Building material stores, manufacturing plants, machinery repair shops, food and beverage plants, farms, home use |

| Video shipment inspection: | if |

PET Plastic Belt Production LinePET Packing Belt Equipment Belt Making Machine

Features and advantages of pet carrier production line:

High tensile strength, limited elongation, good impact resistance, economical, easy to operate and safe. It is an ideal substitute for traditional steel strips.

Packaging of paper, wood, cotton, fiber, metal, aluminum-plastic profile products and various pallets.

featurePet belt production line :

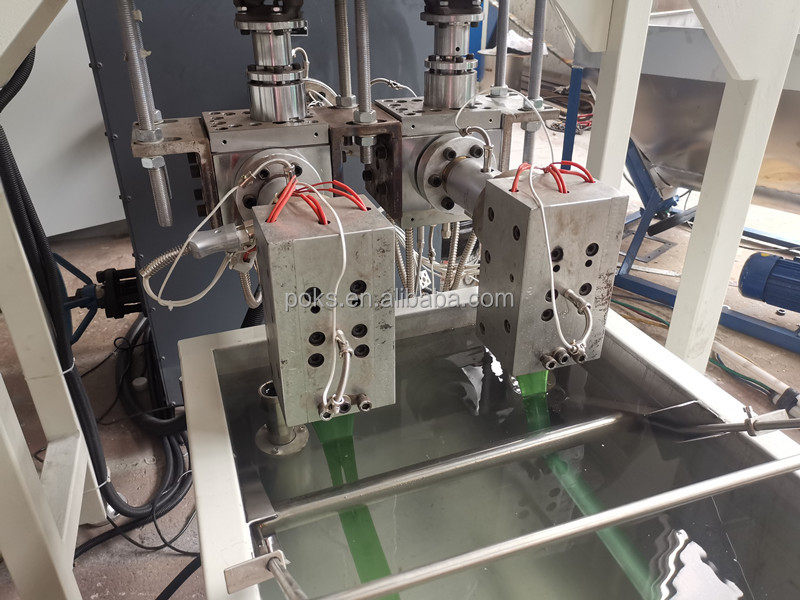

1. Special twin-screw extrusion technology and single-screw extrusion technology can be selected according to customer needs

2. Processing 100% recycled PET flakes (after Grace-M PET washing and recycling line)

3. PC automatic control of the whole line for uniform plasticization and stable extrusion

4. According to different requirements, replace the A coating material to make the strap have better special functions. For example, the belt used to pack cotton can improve the breaking strength and joint strength when welding the belt

5. Two piston melt filters with exhaust design and backwash

6. Number of straps: 1, 2, 4, 6

-

mini plastic extruder laboratory micro single screw extruder extrusora

-

20~110mm PE pipe production line plastic pipe making machine

-

Custom Elastic Band Making Machine

-

High precision 0.02mm finishing winding 3D filament making machine hot sale in 2020

-

Certified line extruder SJ30/25

-

EPE foam sheet machine/PE foam network pipe extrusion line,Ellie Whats 008613780912769

-

HDPE plastic pipe making machine/plastic water pipe production line/plastic energy pipe making machine

-

Wood Plastic WPC Door Frame Forming Machine Production Line

-

150mm screw pp pe waste plastic recycling extrusion granulation pelletizing machine production line

-

WPC profile extruder for the manufacture of WPC floor and wall panels from recycled PP/PE plastic and wood waste