EPE foam sheet machine/PE foam network pipe extrusion line,Ellie Whats 008613780912769

-

Supplier: Longkou Haiyuan Plastic Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Ms Amy Zou -

Price: $10000.00 /set -

Min. Order: 1 set

| raw material: | LDPE pellets | Main selling points: | high productivity |

| Video shipment inspection: | if | After-sales service provided: | On-site service by overseas engineers, video technical support, free spare parts, on-site installation and commissioning training, on-site maintenance and repair services, online support |

| Core components: | Bearings, motors, pumps, gears, PLCs, others, pressure vessels, engines, gearboxes, screws | Ellie's whatsApp: | 008613780912769 |

| product: | PE sheet film | Showroom location: | Egypt |

| Name: | extruder | application: | sheet |

| Packaging Details: | EPE foam sheet manufacturing machine/PE foam network pipe extrusion line standard export packaging EPE foam sheet production machine/PE foam network pipe extrusion line wooden box | Supply capacity: | 100 sets per year |

| Origin: | Shandong China | Marketing Type: | Hot Products of 2021 |

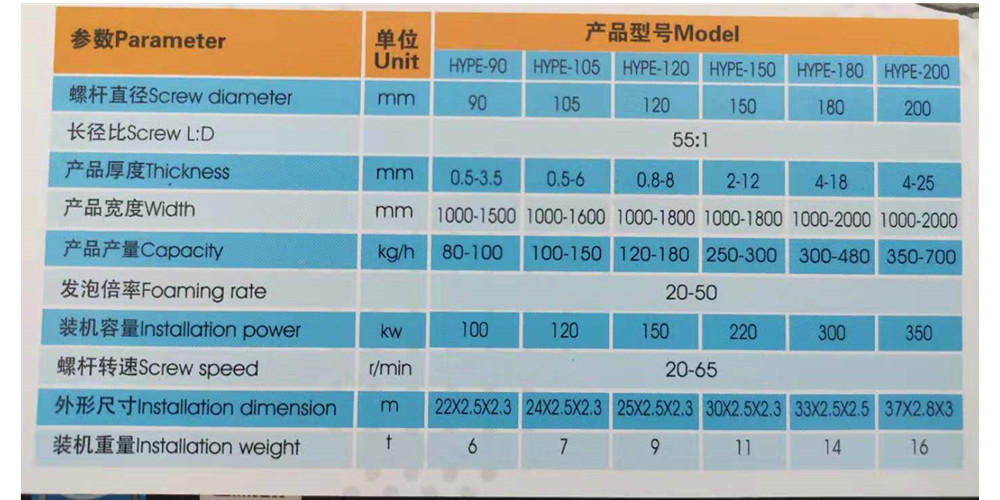

| Screw aspect ratio: | 55:1 | Mechanical test report: | if |

| weight: | 16 tons | Automatic level: | fully automatic |

| Package preview: | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | |

| Health status: | new | Screw diameter (mm): | 200mm |

| Local service location: | Egypt | Customs code: | 8477800000 |

| brand: | Haiyuan | Core component warranty: | 1 year |

| Warranty: | one year, one year | port: | Qingdao |

| Power (kW): | 100 | Screw speed (rpm): | 100 rpm |

| Plastic processing: | polyethylene | color: | customizable |

| Screw material: | 38CrMoALA | Screw design: | single screw |

| After warranty service: | Video technical support, online support, spare parts, on-site maintenance and repair services | Voltage: | custom made |

| Applicable industries: | manufacturing plant | Dimensions (L*W*H): | 37x2.8x3 meters |

Features of EPE foam sheet production line:

1. Damping, antistatic, dustproof

2. Packaging materials: electronic equipment, ceramics, glass products, furniture

3. Thermal insulation materials: agriculture, construction

Introduction of EPE foam sheet production line:

PE foam sheet extruder produces fine closed-cell polyethylene foam sheet, through our uniquely designed screw and barrel system, using butane foaming agent, talcum powder or talc powder masterbatch and anti-shrinkage agent (GMS Surfactant for short) through accumulated experience and advanced technology.

1. PE foam and related products are made of PE resin, which is expanded and formed by heating and extrusion. And easy to decompose, friendly to the environment.

2. The main function is cushioning protection and warmth retention.

3. Modern mass-produced products, especially the most widely used in the export packaging industry, including the electronics industry (such as PC computers, notebook computers, electronic chips and parts, inverters, TV sets, air conditioners, refrigerators), furniture, glassware, clothing, metal parts, etc.

4. Anyone who wants to export modern packaging must use PE foam for the following reasons: Many countries prohibit the use of bubble film, EPS and plastic film for packaging. Paper packaging is too expensive.

5. There are many types of PE foam products: sheets for direct winding and bag making; PE sheets can be covered with plastic film, kraft paper, and aluminum foil. It can be laminated (by electricity or LPG flame) into thick blocks. They are then cut into different containers or frames. PE fruit nets are directly used for wrapping fruits and small objects.

If special molds are added, different door hinges and furniture packaging profiles can be produced.

Specification

-

mini plastic extruder laboratory micro single screw extruder extrusora

-

20~110mm PE pipe production line plastic pipe making machine

-

Custom Elastic Band Making Machine

-

High precision 0.02mm finishing winding 3D filament making machine hot sale in 2020

-

Certified line extruder SJ30/25

-

HDPE plastic pipe making machine/plastic water pipe production line/plastic energy pipe making machine

-

PET Plastic Belt Production LinePET Packing Belt Equipment Belt Making Machine

-

Wood Plastic WPC Door Frame Forming Machine Production Line

-

150mm screw pp pe waste plastic recycling extrusion granulation pelletizing machine production line

-

WPC profile extruder for the manufacture of WPC floor and wall panels from recycled PP/PE plastic and wood waste

Other Products

-

$3000.00 / set

$3000.00 / set -

$3000.00 / set

$3000.00 / set -

$3600.00 / set

$3600.00 / set -

$60.00 / set

$60.00 / set -

$33000.00 / set

$33000.00 / set