Disposable Foam Plate Production Line/Vacuum Forming Lunch Box Making Machine/Fast Food Foam Plate Production Machine

-

Supplier: Longkou Haiyuan Plastic Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Ms Amy Zou -

Price: $3000.00 /set -

Min. Order: 1 set

| Product Type: | Fast food box | type: | Vacuum forming machine |

| Applicable industries: | Manufacturing plants, food and beverage plants | Health status: | New |

| Production speed (times/hour): | 1200 | Video factory inspection: | if |

| manufactures: | Foam lunch boxes, food containers, foam boards and glass | power supply: | 380 volts |

| Mechanical test report: | if | Maximum forming height (mm): | 100 mm |

| Applicable Materials: | PS Polystyrene | Voltage: | 380V or customized |

| Machine Type: | Plastic Vacuum Forming Machine | Dimensions (L*W*H): | 30*6*3m |

| Plastic Type: | PS, EPS, polystyrene | Marketing Type: | New Year 2022 |

| Forming width (mm): | 1100 mm | port: | Qingdao Port |

| Molding machine capacity: | 600,000 pieces of foam disposable plates/lunch boxes | Sheet thickness: | 0.8--5 mm |

| Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump | Name: | Lunch Box Vacuum Forming Machine |

| Exhibition Hall Location: | Egypt | Automatic: | Yes |

| Weight (T): | 20 T | Keywords: | Disposable foam plate making machine |

| Payment Terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Forming Type: | Plastic Vacuum Forming Machine |

| Origin: | Shandong Province, China | Heating power (kW): | 55 kW |

| Molding length (mm): | 1400 mm | The whole production line includes three machines: | Sheet Extruder + Molding Machine + Recycling Machine |

| Key selling points: | Automatic | Packaging Details: | 1. Foam food container making machine requires three 40ft HQ 2. PS foam food box making machine production line about 30 tons 3. Disposable foam board making machine at Qingdao port 4. Standard packaging for export foam tray machine |

| Core component warranty: | 1 year | Package Preview: | |

| usage: | Making sheets and food boxes/foam boards/food containers/water-absorbing trays | Supply Ability: | Annual production of 50 foam lunch box forming machines |

| Warranty: | 1 year | Brand Name: | Haiyuan Brand |

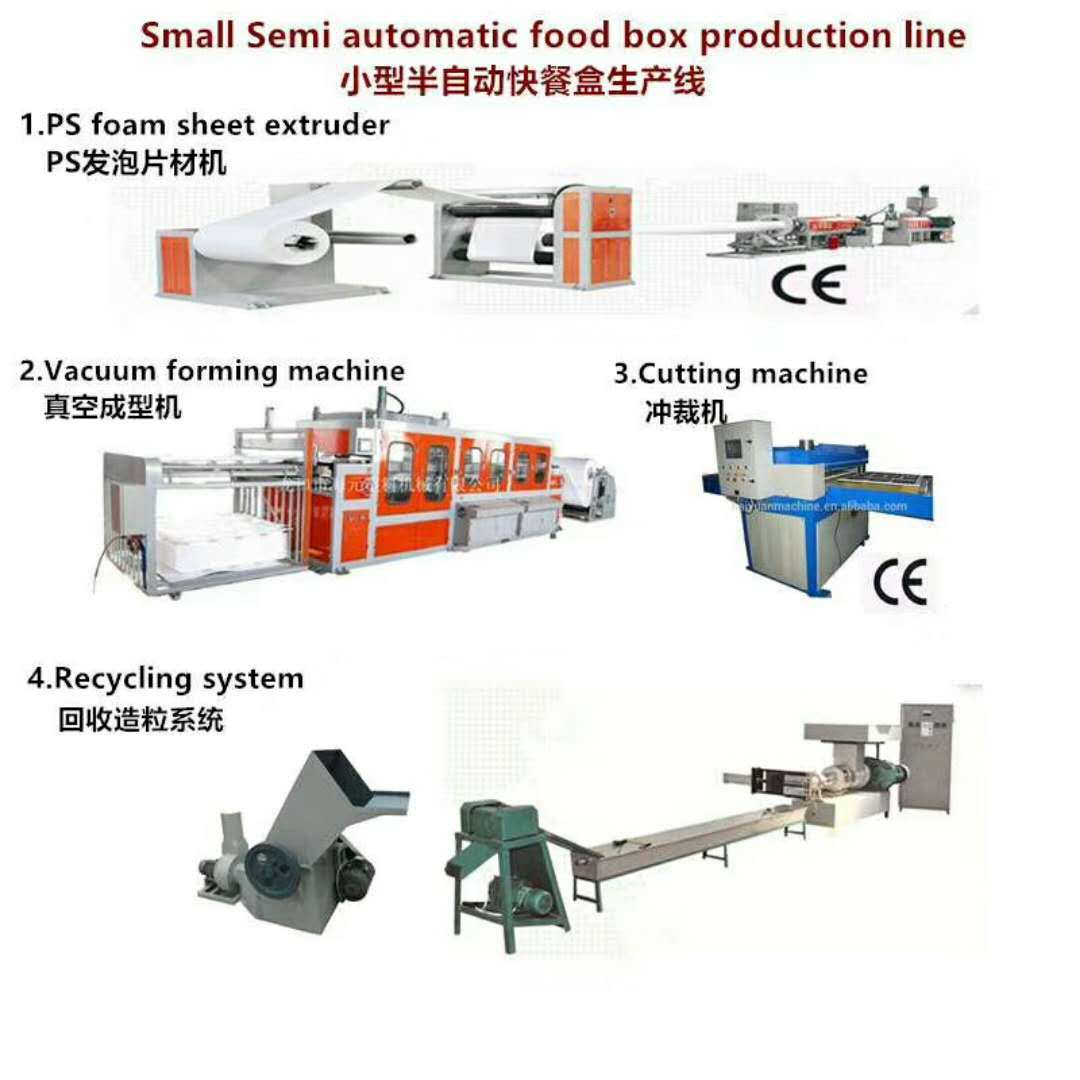

2.PS foam food container production line, PS foam sheet production line

3.PS foam food box making machine, foam food tray machine, foam food tray machine

4. Takeaway food box making machine, foam food container machine, foam food box making machine

5.PS foam absorbent tray making machine, food container vacuum forming machine

6. Foam egg tray making machine, foam hamburger box making machine, pizza box making machine

7.PS foam ceiling machine

* PS foam sheet extruder + * Vacuum forming machine + * Recycling machine

1.PS foam sheet extrusion production line

The PS foam sheet extrusion production line adopts the gentian type double-stage series high foaming technology. The raw material is general polystyrene particles. The foaming agent is injected under high pressure during the extrusion process. After extrusion, foaming cooling, shaping, and traction, it is rolled into a finished PS foam sheet roll.

In our factory, we not only produce extruders, but also PS foam sheet rolls, we can produce sheet rolls of different thickness, different hardness, different colors, if you have no experience, please don't worry, we can help you! ! When you visit our factory, you can see the machine in operation

PS foam sheet extrusion production line parameters | ||||||||||

scope | unit | HY-75/90 | HY-105/120 | HY-110/130 | HY-135/150 | |||||

capacity | kg/hour | 80-100 | 200-240 | 230-260 | 280-360 | |||||

Plate thickness | Millimeters | 1-4 | 1-4 | 1.5-5 | 2-5 | |||||

Sheet width | Millimeters | 640-1080 | 640-1080 | 800-1080 | 900-1080 | |||||

Foaming rate | 10-22 | |||||||||

Cooling method | Air cooling, water cooling | |||||||||

Cutting method | Single | |||||||||

Butane gas pressure | MPa | 0.9-1.2 | ||||||||

Installed power | kilowatt | 160 | 200 | 260 | 320 | |||||

Installation Decisions | rice | 24*6*3 | 30*6*3 | 32*6*3 | 35*8*63 | |||||

power supply | Three-phase 380v50Hz Three-phase 220v60Hz | |||||||||

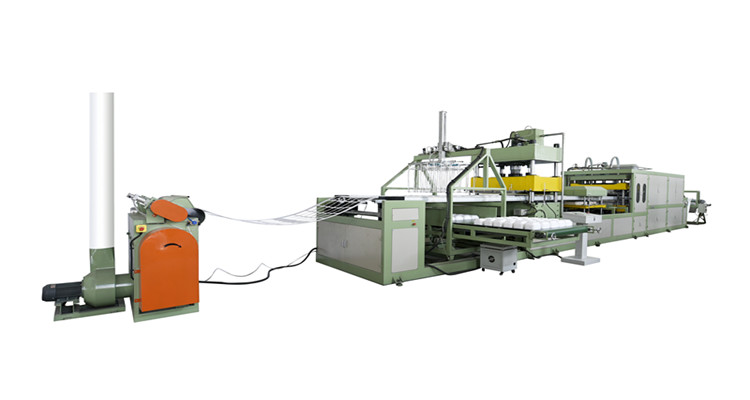

2. Disposable foam plate making machine/lunch box vacuum forming production line/PS foam plate fast food plate making machine

Disposable foam plate making machine/lunch box vacuum forming production line/PS foam plate fast food plate making machine feature

1) Takeaway food container making machine Vacuum forming, cutting and stacking integrated

2) Foam plate machine,Foam board foam cup machineIt can produce PS foam food boxes, disposable foam boards, take-away food containers, foam egg trays, hamburger boxes, foam food boxes, foam food plates, foam bowls, fruit trays, foam absorbent trays, foam ceilings, etc., which are widely used in the packaging of hot and frozen foods in supermarkets, shops and other places.

3) Foam box forming machine, foam food tray machine heating zone adopts far-infrared ceramic heater and heating tube, so that the machine can get the most stable temperature.

4) The PS foam lunch box machine uses a temperature digital system, which allows workers to quickly understand the temperature of each heating zone.

5) Foam Food Box Flat Glass Making MachineAdopt PLC controller and touch screen to control the working programmer. PLC can store more than 10 sets of mold information. When changing the mold, there is no need to set the data again, which is easy to operate.

Disposable foam plate making machine/lunch box vacuum forming production line/PS foam plate fast food plate making machine PageParameters | ||||||||

scope | unit | HY-1100/1100 | HY-1100/1250 | HY-1100/1400 | ||||

Molding area | Millimeters | 1100*1100 | 1100*1250 | 1100*1400 | ||||

Cut-off height | Millimeters | 160 | ||||||

Production efficiency | Ions | 3-4 | ||||||

capacity | Pieces/day | 400,000 pieces | 500,000 pieces | 600,000 pieces | ||||

Installation Dimensions | rice | 19*6*3 | 21*6*3 | 24*6*3 | ||||

Mounting Powder | kilowatt | 150 | 160 | 180 | ||||

power supply | Three-phase 380v50Hz 220v60Hz | |||||||

3. Crushing and recycling granulator

-

Low Price New Plastic Vacuum Forming Machine to Make Disposable Plates/Foam Tableware/Food Containers

-

Used cup machine for vacuum plastic forming

-

Acrylic Forming/Making/Vacuum Tub Forming Machine

-

Durable desktop acrylic pvc plastic vacuum forming machine

-

PS Expanded Styrofoam Pan Container Pan Tray Food Box Small Production Machine, Ellie Whats 008613780912769

-

FUSHI brand PS EPS thermocol foam board container tray mould machine

-

small mini desktop acrylic pvc plastic vacuum forming machine/thermal vacuum forming machine

-

best price vacuum forming machine

-

BSX2030 Super Discount High Modular Acrylic ABS PP Thermoforming Deep Vacuum Forming Machine

-

Acrylic thermoforming machine Signage sign vacuum forming machine plastic sheet vacuum former with CE

Other Products

-

$3000.00 / set

$3000.00 / set -

$10000.00 / set

$10000.00 / set -

$3600.00 / set

$3600.00 / set -

$60.00 / set

$60.00 / set -

$33000.00 / set

$33000.00 / set