Laminating Machine Automatic PUR Hot Glue MDF Board Lamination PET Film Woodworking Machine

-

Supplier: Jinan Kamac International Trade Co., Ltd. -

Region: Shandong, China -

Contact: Mr ANGELA ZHANG -

Price: $50000.00 / 1 - 4 units

$48000.00 / >=5 units -

Min. Order: 1 unit

| Packaging Details: | Film Packaging Fixing To Container Laminator Automatic PUR Hot Glue MDF Board Lamination PET Film Woodworking Machine | product name: | Laminator Automatic PUR Hot Glue MDF Board Laminated PET Film |

| Health status: | new | brand: | Carmack |

| usage: | Glass magnesium board, calcium silicate board, gypsum, fireproof board | Function: | Pressing and calendering |

| strength: | 80 | Substrate: | PVC film |

| Package preview: | Showroom location: | USA, Germany, Japan, Australia | |

| Main selling points: | high accuracy | Weight (kg): | 6000 |

| port: | any port in China | Voltage: | 220V/380V |

| Dimensions (L*W*H): | 18X1.6X1.9M | Core components: | PLC, motor, water pump |

| Mechanical test report: | if | Core component warranty: | 5 years |

| Video shipment inspection: | if | Applicable industries: | Construction material store, manufacturing plant, construction work, others |

| payment terms: | L/C, D/P, T/T | Supply capacity: | 2000 units per year |

| Marketing Type: | Hot Products of 2022 | Origin: | Shandong China |

| Warranty: | 5 years | Key words: | Woodworking laminating machine |

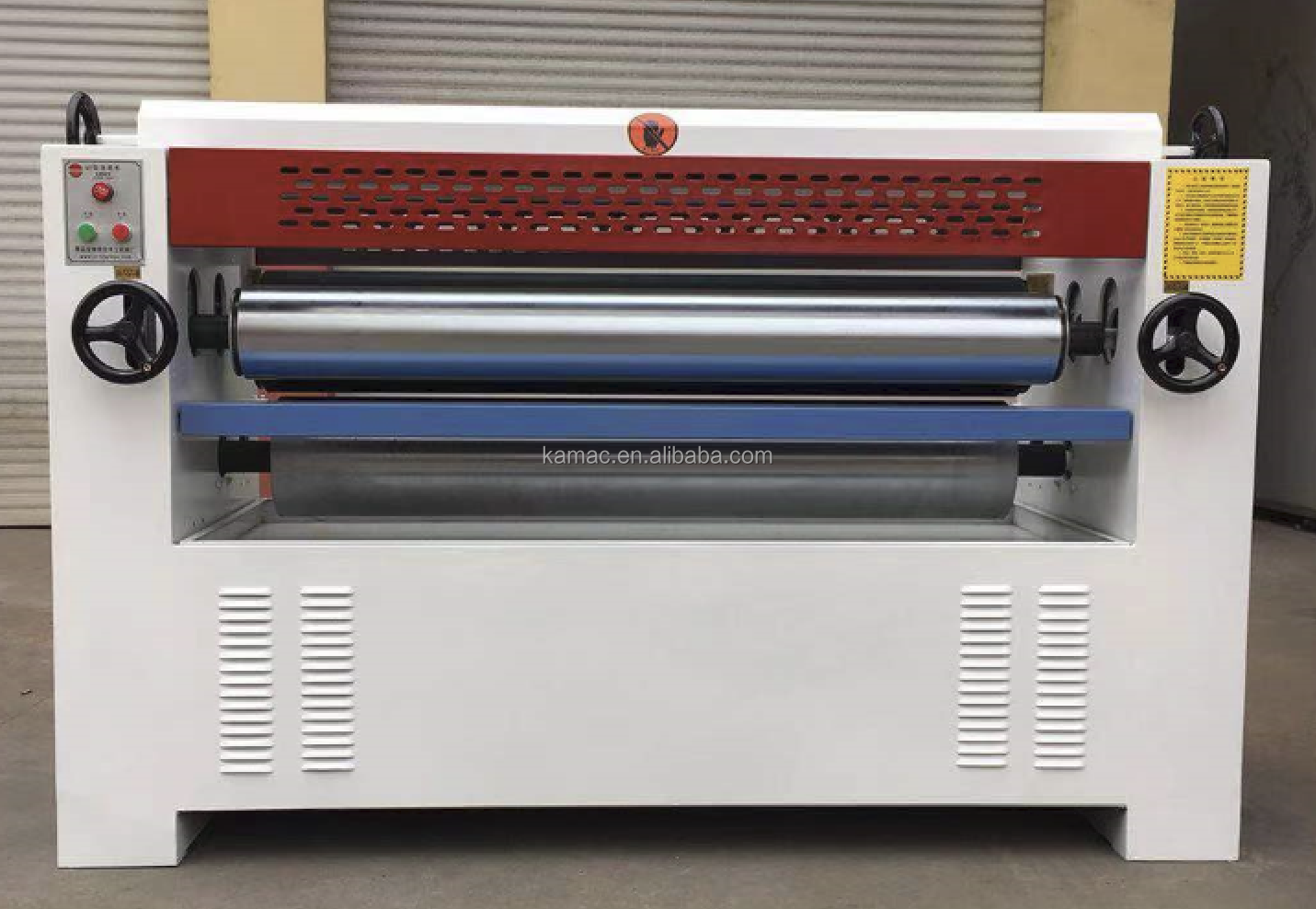

Polyurethane Laminated Fabric Laminating Machine

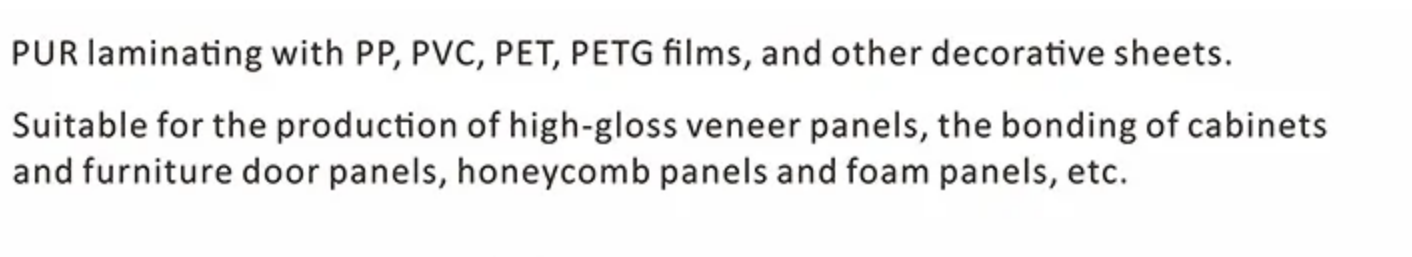

Equipment basic materials; wood, metal, glass, calcium silicate board, glass magnesium board, gypsum board, cement board, ABS, PVC, PC and other metal materials such as bonding application characteristics.

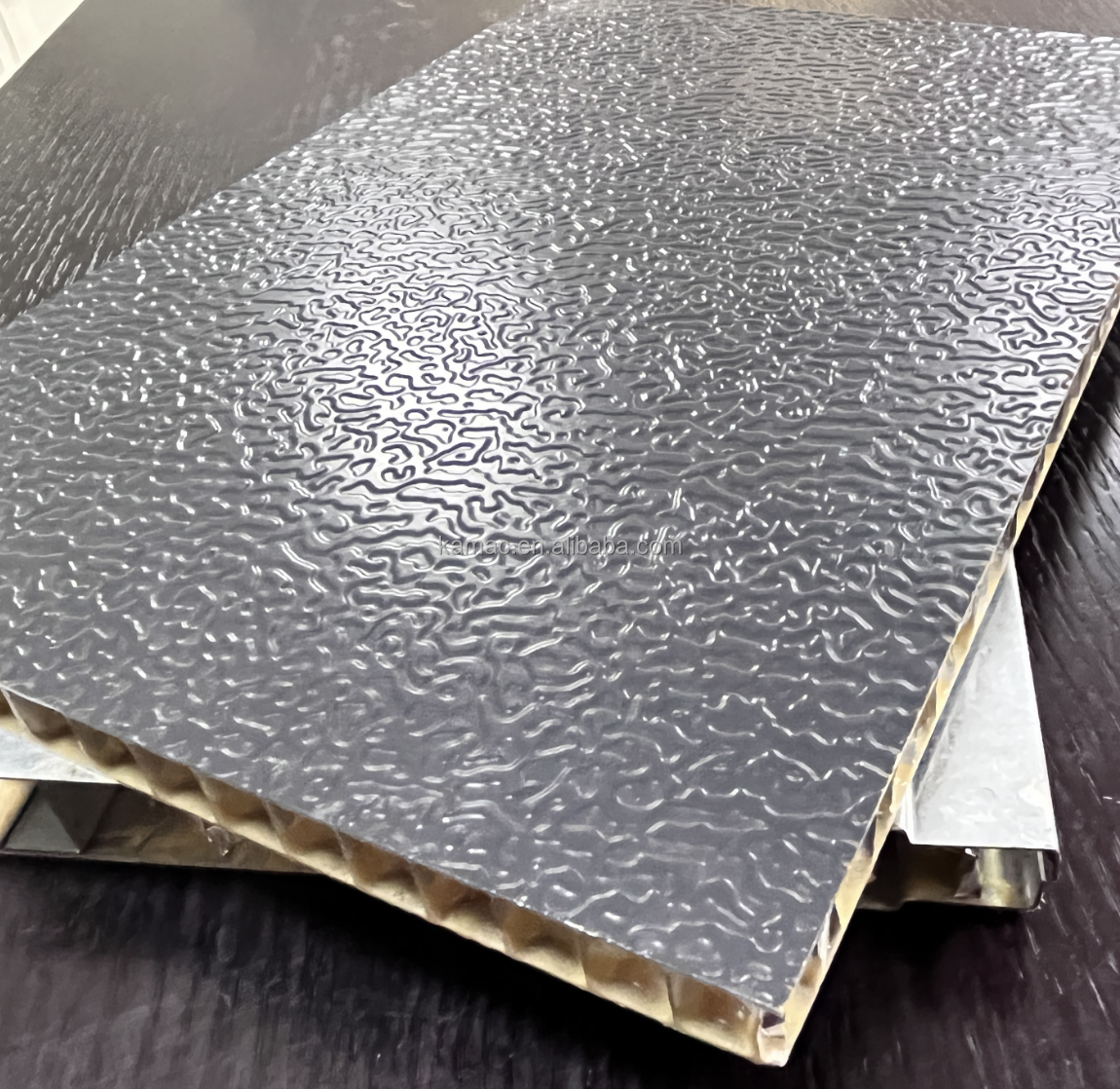

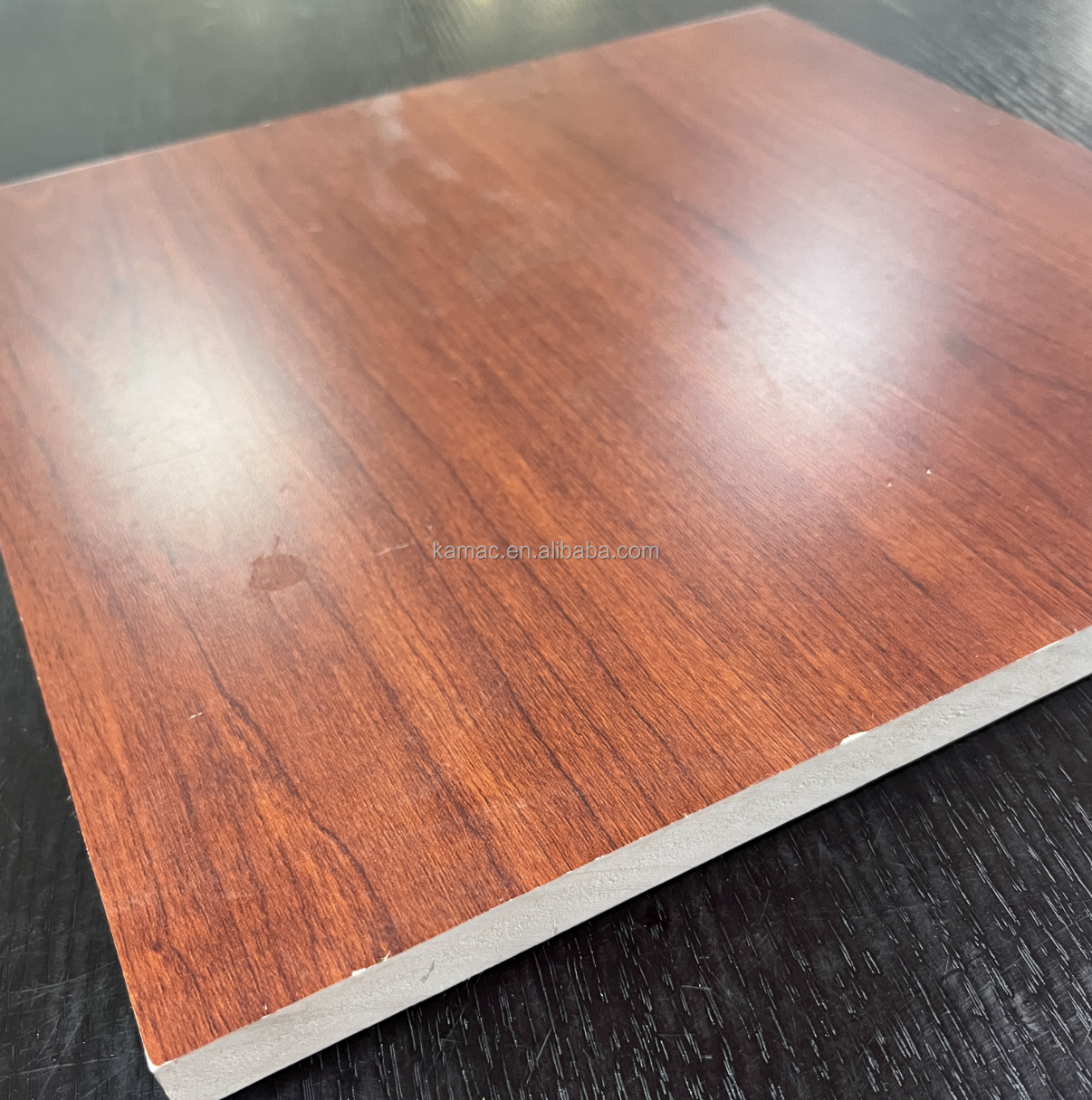

Product display:

This is the most suitable flat lamination machine for PUR hotmelt adhesives, suitable for all kinds of materials on the market. PUR hot melt adhesives provide a fast chemical reaction and excellent adhesion.

1) including: indexing table, cleaning unit, preheating tunnel and connecting drive roller conveyor.

2) oiled on one side, while using oil to heat the metering roller and the rubberizing roller. Precise heating capability creates a stable and uniform temperature, combined with the melting unit to provide the best production output capability.

3) Semi-automatic foil laying station on calender roll, suitable for lamination of various foil/film materials. Simple, flexible and effective with minimal material waste.

4) Two sets of cold pressure rollers provide enough pressure for various lamination combinations. Adjustable pressure, connectable expansion shaft and strong baked film lamination.

5) Existing drive roller conveyors may have protective film laminated rollers.

| Function parameter | |

| model | HY-PUR-1400A |

| Product size(mm) | 14000*5000*3000MM |

| Substrate | MDF, particle board, plywood, PVC board, aluminum veneer |

| surface material | PVC, PET, acrylic board, HPL board, aluminum board, CPL, etc. |

| glue | PUR hot melt adhesive, PVAC cold adhesive; |

| finished product | Furniture panels, door panels, Kichent cabinets; |

| Technical Parameters | |

| design | Independent research and development |

| running speed | 15M/min |

| heating power | 32 kW |

| suppression system | pneumatic |

| Heating system | oil heating system |

| Electrical parts | Schneider |

| color | yellow and white |

| certified | CE and ISO:9001 |

| payment terms |

TT (Bank Transfer), LC (Letter of Credit at Sight), Western Union, Money Grams, trade assurance |

| Supply capacity | 100 sets per month |

| delivery time | 4 weeks for standard products, 6-12 weeks for customized products |

| packaging details | Plastic protective film and wooden box |

--Professional sales team, composed of diligent, energetic and innovative international talents.

--Excellent logistics service ensures timely delivery of goods to all over the world by sea, air, road and railway.

——A well-coordinated and professionally managed operating system.

--Professional team of after-sales experts ensures that all of our products are well maintained and perform.

KAMAC is known for a highly collaborative culture that values the contributions of our diverse teams both within the company and in the wider community. Our style is open, service focused and friendly. We believe that our commitment to client service, commerce and teamwork benefits our clients and enhances effective business relationships.

-

PVC door/window/wall/ceiling frame woodworking cold glue hot melt glue profile wrapping machine

-

Cpl cold solvent glue profile wrapping machine engineering wood veneer solvent glue profile wrapping machine

-

Woodworking wooden window door frame furniture MDF PVC veneer profile wrapping machine

-

1000kg steel plate material cost-effective profile pvc automatic laminating machine

-

Wooden door wrapping paper coating profile packing machine cold glue profile packing melamine laminating machine

-

best price wood door laminator

-

PUR Hot Melt Adhesive PVC and Veneer Laminated Profile Winding Machine

-

Automatic coating machine LB-TM2480D Automatic wood PVC film coating machine

-

PVC veneer profile winding machine (XJ-IIB)

-

Plywood, MDF, Particleboard Roller Glue Coating Machine