Gold Testing Machine Electronic Exf9600 Xrf Machine Spectro Lab With Price Fischer Stone Black -Toilet

-

Supplier: Nanchang Tanzhi Technology Co., Ltd. -

Region: Jiangxi, China -

Contact: Ms Shannon Hu -

Price: $3999.00 /unit -

Min. Order: 1 unit

| focal length: | 1 | accuracy: | 0.01% |

| delivery time: | 7-15 days | Function: | Metal Purity Analysis |

| Test material: | metal gold silver alloy | Package preview: | |

| type: | Xrf Analyzer | Supply capacity: | 1000 pieces per month |

| brand: | Tianzhengtong | product name: | XRF RoHS Halogen Tester |

| weight: | 38 kg | feature: | easy to use |

| model: | TZT-Electronic gold testing machine | Wavelength range: | 0.22mm |

| Packaging Details: | Gold Tester Electronics Exf9600 Xrf Machine Spectrum Lab Band Price Fischer Black Stone - High End Crate for Toilets | size: | 650*450*350mm |

| application: | Pawn Shop Jewelry Manufacturing | payment terms: | L/C, T/T, Western Union, MoneyGram |

| port: | Shenzhen | Warranty: | 1 year |

| Origin: | Guangdong, China | Measuring range: | S to U |

| Name: | Gold Testing Machines Electronic Exf9600 Xrf Machine Spectro Lab With Price Fischer Black Stone -Toilet | |||

| Testable elements: | elements from sulfur to uranium RoHS restricts harmful elements Pb/Hg/Cd/Cr/Br HF limit halogen harmful element Br/Cl The eight heavy metals in En71-3 are lead (Pb)/arsenic (As)/antimony (Sb)/barium (Ba)/cadmium (Cb)/chromium (Cr)/mercury (Hg)/selenium (Se) |

|||

| Equipment principle: | XRF Energy Dispersion | Collimator: |

Spot: φ1mm, 3mm, 5mm (software automatic selection) |

|

|

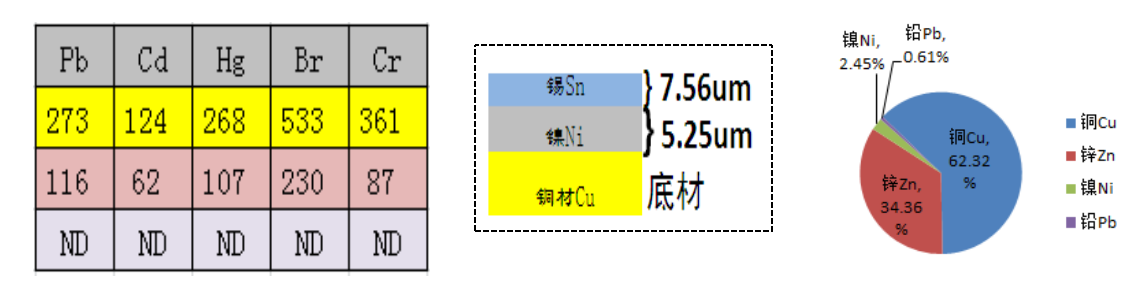

Minimum detection limit |

Content analysis: 0.01%-99.99% RoHS: Cd/Cr/Hg/Br≤2ppm Pb≤5ppm Cl≤60ppm |

Voltage/power: | 100-220v/128w | |

| detector: | Si-Pin Probe (Made in USA)145±5eV |

X-ray tube window material |

metal window |

|

|

Sample Form/Scope |

solid, liquid, powder; |

operating system: | countdown 7 | |

| working environment: | - 11 ~ 46°C | advantage: | excellent cooling system | |

| Battery support:: | No | intelligence: | automatic protection | |

| Label/General/Thermal Printer: | support | Sample cavity size | 28*28*20cm | |

|

high voltage source |

0-50kev,0-2mA |

Machine net weight: |

36 kg | |

|

Built-in computer: |

Yes | Machine size: | 650×450×350mm | |

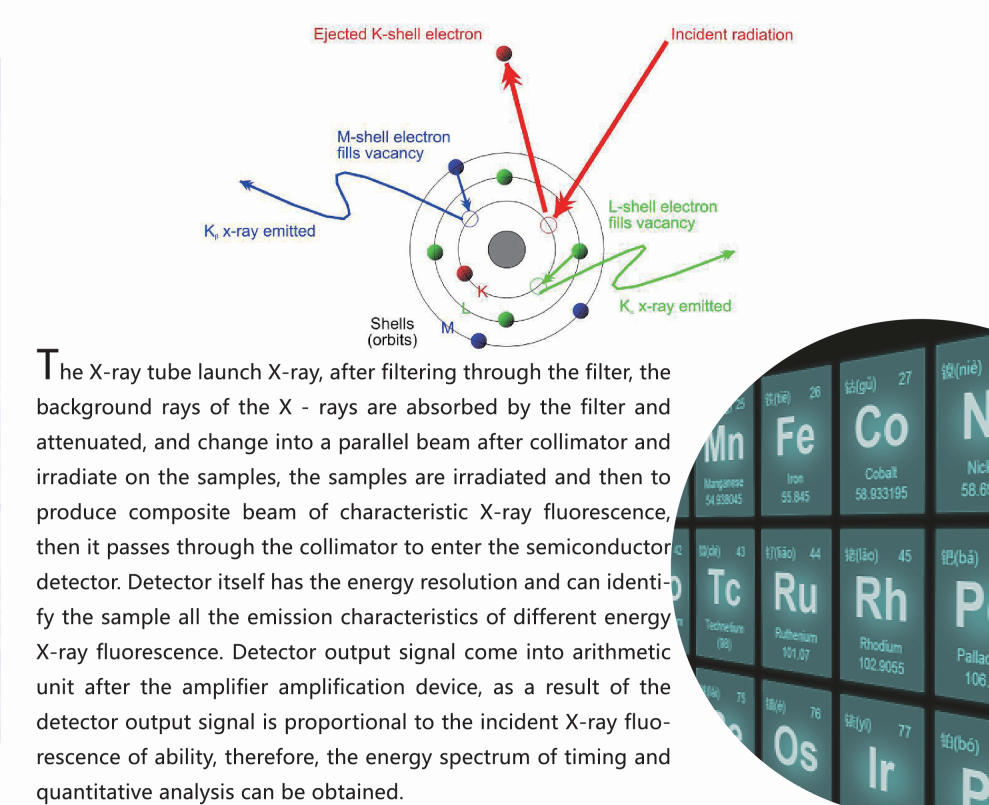

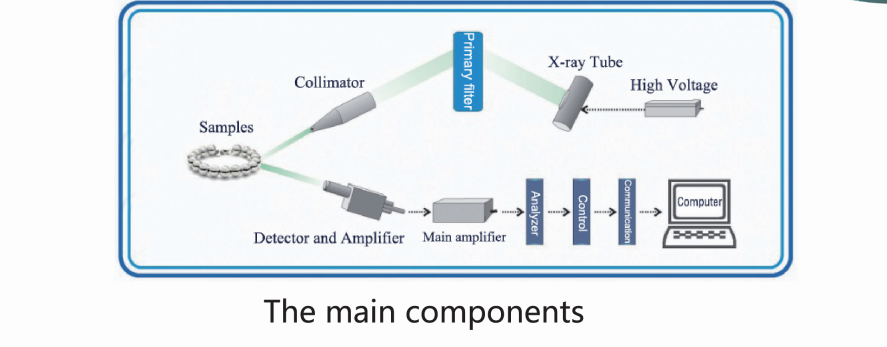

working principle:

Energy dispersive X-ray fluorescence spectrometry (XRF) is a physical elemental analysis method. In recent years, XRF has played a huge role as a rapid detection method in electronics, electrical appliances, jewelry, toys, food, building materials, metallurgy, geology, plastics, petroleum, chemical, pharmaceutical and other industries.

XRF has the advantages of fast, non-destructive, multi-element simultaneous analysis, and low cost.

XRF W7 is a high-end integrated model, triple radiation protection system, humanized operation interface, comprehensive application of empirical coefficient method and basic parameter method v8.0 analysis software. That is, it can detect Pb, CD, Hg, Br in PBDE and PBB, Cr in hexavalent chromium, and Cl and Br elements in the halogen-free directive. It can fully meet RoHS/WEEE/halogen-free control requirements. The well-designed open working curve function is especially suitable for the process control of multi-material factories. And it has superior test performance in the analysis of copper alloy, iron alloy, aluminum alloy and other metals, and the test stability and accuracy are relatively excellent in the industry.

XRF W7 is widely used to detect electroplating layers, such as iron galvanization, iron chrome plating, copper nickel plating, gold plating, copper tin plating, etc.

In addition, XRF is widely used in on-site analysis and process control analysis, such as scrap metal recycling, soil on-site testing, material online testing, etc.

1. Highly integrated industrial control motherboard, multi-point toughness, stable and fashionable

2. Using a real 5 million pixel camera, the sample observation is clear and the position is accurate

3. The secondary intensity extraction algorithm of unique elements is used to improve the detection limit of trace elements

4. Sound reminder function, convenient for the operator to multi-task

5. The water light control module is used to make it easier for the operator to understand the status of the instrument

6. The software integrates multiple RoHS restriction standards in the same mode.

7. The same software integrates composition analysis and coating thickness analysis.

Our advantage:

10. Integrated data statistics function, which is convenient for the quality department to filter and count suppliers, material names, components, test conditions, etc. in different time periods.

11. Provide an open working curve calibration function, which can determine the best method and control scheme for the detection of harmful substances for users.

12. Automatic inspection software and fault judgment function to ensure that the instrument is always running in the best working condition, and eliminate abnormalities in time.

13. Analyze the data backup/restore function to avoid losses caused by misuse or other reasons, and ensure the safety of data and system files.

14. Customize the test report output format (Excel, PDF, list, etc.) according to user needs to meet various statistical requirements of the factory.

15. With the core hardware real-time temperature monitoring function, through the heat source analysis system and real-time control, the hardware heat can be discharged in time. To reduce the impact of temperature changes on the detector.

16. Support large sample test function, with process guidance design.

-

HM-100 haze meter, suitable for plastic sheets, films, glass, LCD panels, touch screens, etc.

-

Quick Demand Tarmo Scientific NEton XL3t G0LDD Handheld XRF Analyzer

-

LHB721 Spectrophotometer Best Price Benchtop Spectrophotometer UV Vis Spectrophotometer

-

The Nton XL3t 900S XRF Analyzer offers features designed to increase your productivity and profitability

-

HiYi Master ECO- High Quality High Technology Cheapest Milk Fat Salt Freezing Point Test Ultrasonic Milk Analyzer

-

DW-AA320N Double Beam Atomic Absorption Spectrophotometer AAS Flaka Price Spectrometer

-

New Thermos Scientific Niton XL2 980 Goldd XRF General Metals Mining Precious Metals

-

Vant C Series C Handheld XRF Element Analyzer Handheld XRF Analyzer

-

Integrating sphere lighting test high-quality integrating sphere 0.3m 0.5m 1.0m 1.5m 2.0m optional lumens

-

Scienovo SN-FTIR-530A Fourier Transform Infrared Spectrometer

Other Products

-

$100.00 / piece

$100.00 / piece