Factory industrial sugar cane red and white sugar production line beet sugar refinery sugar making machine

-

Supplier: Zhangjiagang Genyond Machinery Co., Ltd. -

Region: Shanghai, China -

Contact: Mr Wakin Yong -

Price: $950000.00 /set -

Min. Order: 1 set

| Voltage: | 220V 380V 415V 440V,380V 50Hz | capacity: | 10-100TPD |

| Function: | multifunctional | After Warranty Service: | Video Technical Support |

| brand: | Jeannion | After-sales service provided: | engineer |

| Applicable industries: | Food and Beverage Factory,Food and Beverage Store | Warranty: | 1 year |

| payment terms: | L/C, Western Union, T/T | Package preview: | |

| Core component warranty: | 1 year | usage: | sugar |

| MOQ: | 1 set | Packaging Details: | wooden box |

| Origin: | China Shanghai | Supply capacity: | 5 sets per year |

| Video outbound inspection: | if | strength: | 400 kW |

| Core components: | PLC, engine, bearing, gear | port: | Shanghai |

| raw material: | raw sugar | type: | production line |

| Processing type: | complete processing line | Dimensions (L*W*H): | by capacity |

| application: | sugar production | Mechanical test report: | if |

| Marketing Type: | normal product | Health status: | new |

| weight: | 80000 kg | Showroom location: | not any |

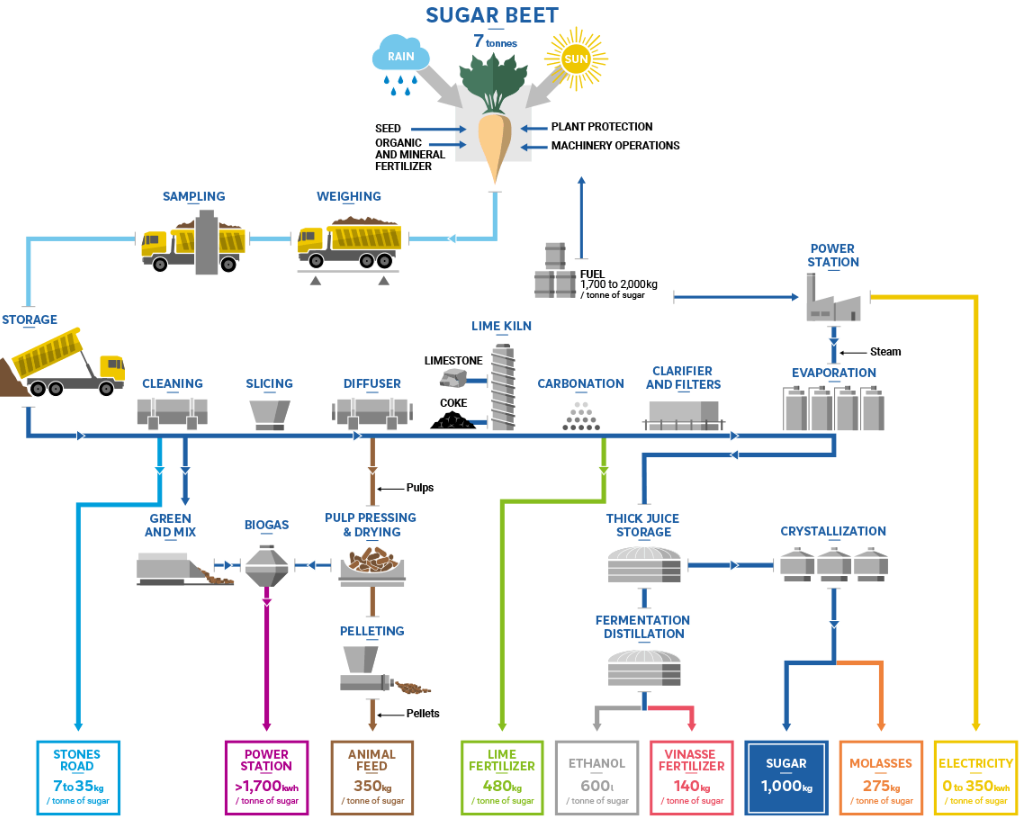

Sugar beet processing generally goes through raw material pretreatment, exudation, cleaning, evaporation, sugar boiling and other processes. Beet sugar production first transports the beets from the pit to the beet workshop (except for dry transportation), after weeding, stone removal and cleaning, the beets are shredded, infiltrated into the interior, reversed into hot water for extraction from beet and other silk soluble Solid sugar. Add lime juice from the seepage device for extraction, then fill with carbon dioxide, mix, precipitate and filter to remove non-sugar substances. The sulfur dioxide in the decolonized sugar juice is further utilized, and then sent to a multi-effect evaporator for concentration, 65BX. send to

Boil the sugar pot to crystallize, then separate, dry, refine the sugar, pack and leave the factory

Index section

1. Heating temperature indicator, oozing juice at 45°C

2. Prelime juice 85℃

3. Fully charge the carbon before 90°C

4. The first two carbons are fully charged at 95°C

5. 130°C before evaporation

6. Molasses bucket at 80°C

7. Filtration water volume: ≤75%

8. Dry filter mud to light: ≤6.5%

9. pH of clear juice: 7.0±0.1 (pH value of juice after precipitation)

10. Poor purity of mixed juice: ≥1.5GP

11. Clear juice color value: ≤2000IU560

12. Fruit juice heating temperature: 125±2℃

13. Thick syrup Brix: 62~65°Bx

14. pH of refined syrup: 6.0~6.5

15. Color value of refined syrup: ≤2400IU560

sugar fraction index

1. Sugar concentration: 94~96℃Bx

2. A small amount of cooking time: ≤3.5 hours

3. Sugar concentration in syrup: 96~98℃Bx

4. Poor purity of syrup and honey: ≥27AP

5. Syrup cooking time: ≤6 hours

6. Sugar concentration in syrup: 99~103℃Bx

7. Propylene glycol single tank cooking time: ≤10 hours

8. Gravity purity of waste honey: below 38GP

9. The vacuum degree of various syrup cooking is not lower than -0.080Mpa

10. Time for candied fruit in syrup: 4 to 8 hours

11. Disopyramide candied time: 16-24 hours

12. Poor purity between first-grade raw and first-grade washed honey: ≥8AP

13. Massecuite color value: ≤1000IU5

Processing capacity: 50-20000T/day.

The whole production line can be divided into three sections: feeding, raw material reaction (heating, heat preservation, cooling), finished product forming (refining, crystallization), and finished product packaging (transportation, crushing, quantitative packaging). into different paths. Each circuit starts automatically according to the process sequence, and stops automatically according to the material level sensor. The central control room displays the working status of the equipment, and the equipment is overloaded. Faults are displayed in the central control room.

1. The conveying, cleaning and chopping of sugar beets are all automatically controlled by PLC computer with one key, automatic alarm and automatic stop when material is cut off, and the output is controlled by frequency conversion.

2. Automatic water addition, automatic temperature adjustment, automatic pressure control, and large-screen display to monitor data at any time.

4. The water valve, air valve, material valve, and juice valve are all automatically controlled by pneumatic or electric, automatically detect PH value, automatically heat nitrogen, and various pressures. (Air pressure, water pressure) automatic adjustment, large screen display.

Sugar Processing Line

main settings

|

serial number |

describe |

|

I |

production workshop |

|

1 |

Lifting and unloading room |

|

2 |

Raw Sugar House |

|

3 |

the mill |

|

4 |

boiling house |

|

5 |

Lime House |

|

6 |

laboratory |

|

7 |

service shop |

|

8 |

Boiler Room |

|

9 |

power plant |

|

10 |

Electrical System |

|

11 |

instrument control |

|

12 |

Workshop water supply and drainage system |

|

13 |

Non-standard equipment |

|

14 |

erection and installation of equipment and materials |

|

15 |

spare parts for two years |

Technologies that have now become industry reference standards:

Dried beet fields (wet beet fields are also available)

Washing line with dry-feed and front-loading washing machines (classic wet-feed and paddle washing machines also available)

Transport and wash water solids separation and by-product recovery

Drum Beet Slicer

tower diffuser with cosette mixer

Pulp press installation (in cooperation with Babbini)

Three-channel pulp dryer and granulator (CMMCPromill)

Coke, natural gas or fuel fired lime kilns and lime milk plants

Juice Purification Station (Partner for Candle Filters and Filter Presses)

Alcohol/Ethanol Plant

-

Fully automatic and easy to use sugar cube production line for sugar processing lines at great prices

-

Line of sea salt production equipment

-

Small Cube Sugar Product Line/Sugar Cube Making Machine Coffee Best Selling Automatic Hot Selling Commercial Sugar Cube Making Machine

-

Cube sugar production line Sugar processing production line

-

Iodized sea salt production line refinery coarse rock salt refiner lake salt crushing washing and drying machine

-

SNOWY SKY high quality and low price anhydrous sodium sulfate Na2SO4 salt refining plant

-

Sea/Rock/Lake Salt Milling Machine

-

PDV Salt Refinery

-

Cube Sugar Processing Machine For Sale Sugar Cube Press Machine Low Price China Supply

-

Salt Processing Cleaning System

Other Products

-

$5000.00 / piece

$5000.00 / piece