Fully automatic small butter bean soybean peeling machine sheller dry castor locust pea black green coffee bean peeling machine for sale

-

Supplier: Anyang Gemco Energy Machinery Co., Ltd. -

Region: Henan, China -

Contact: Ms Crystal Qin -

Price: $2700.00 /set -

Min. Order: 1 set

| Packaging Details: | All bean peeling machines are packed in export wooden boxes, and the quality and safety are guaranteed. | port: | Qingdao/Tianjin |

| raw material: | wheat corn beans | type: | peeling machine |

| Function: | Wheat corn bean shelling machine | Video outbound inspection: | if |

| Name: | Automatic Small Soybean Peeling Machine Bean Shelling Machine | Showroom location: | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Vietnam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Kenya, Argentina, South Korea, Colombia, Algeria , Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan, Japan, Malaysia, Australia |

| Core components: | gold atom | brand: | GEMCO Bean Sheller |

| Core component warranty: | 1 year | Mechanical test report: | if |

| usage: | food industry equipment | Material: | Stainless steel coffee bean sheller |

| Voltage: | 220V/380V | application: | Wheat Corn Grain Coffee Bean Hulling |

| Origin: | Henan, China | strength: | 11kw small automatic bean peeling and shelling machine |

| Applicable industries: | Food and beverage factory, restaurant, home use | Key words: | Bean shelling machine |

| Supply capacity: | 10 sets per month | Marketing Type: | 2020 New Products |

| Health status: | new | Warranty: | 1 year |

| payment terms: | L/C, T/T | capacity: | 500-700kg/h coffee bean shelling machine |

Fully Automatic Small Bean Peeling Machine Butter Bean/Castor Bean/Pea/Mung Bean/Coffee Bean/Soybean Peeling Machine For Sale

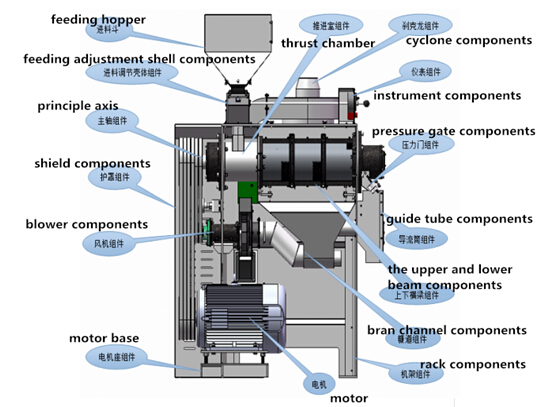

Automatic FTP-18B soybean peeling machine

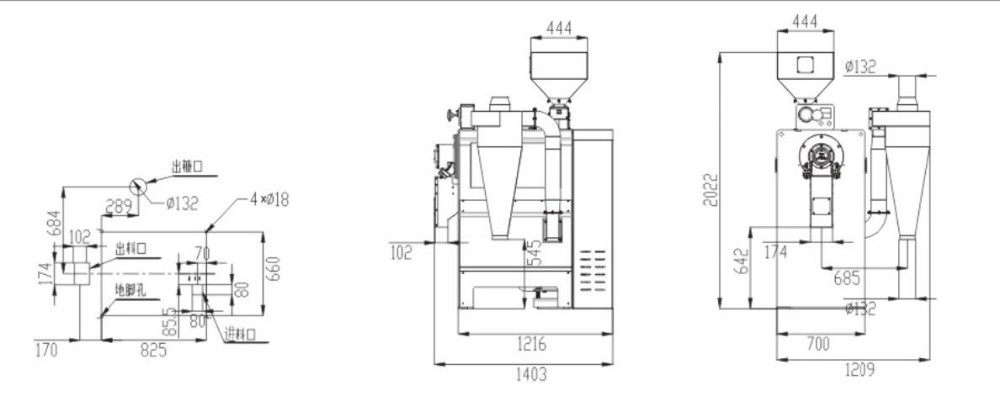

| Model | Capacity (kg/hour) | Power (kW) | Weight (kg) | LWH(mm) |

|---|---|---|---|---|

| FTP-18B | 1000-1500 | twenty two | 850 | 1410*1210*2030 |

click nowGet Catalog and Ex-Works Prices!

It is mainly suitable for small grain workshops and medium-sized grain factories. This product does not need peeling sieves for 1-2 shellings, and the yield rate is over 98%. It can be operated on a stand-alone machine or in-line.

Working principle of soybean peeling machine

Send the soybeans to be dehulled into the hopper; the dehulling point is located between the dehulling stone and the hull. Due to the pressure exerted by the rotating shelling stone, the soybean kernels are separated from the seeds and collected at the bottom together with the shells. The shells or husks are separated from the kernels by means of a blower. Thus, the cleaned grains are collected at the bottom outlet.

The operating efficiency of the hulling machine depends on: the physical characteristics of the rubber seeds, such as size, shape, hardness, etc., the feed rate of the feed, the hulling speed and the effectiveness of the hulling surface in the hulling chamber and the volume blown off the chaff effective air volume and other considerations, including moisture content.

Bean Shelling Machine Installation Dimensions

Consumable parts of bean shelling machine

click nowGet Catalog and Ex-Works Prices!

| thing | quantity | picture |

|---|---|---|

| Rear sieve | 4 |  |

| Front sieve | 2 | |

| propeller | 1 | |

| Head/middle/tail grinding wheel | 1 per person | |

| Sieve calipers | 2 | |

| lip filler | 3 | |

| belt | 4 |

Advantages of our coffee soybean peeling machine

- Novel design, stable operation and low noise.

- Compact structure, easy assembly and disassembly.

- The strong negative pressure shelling is clean and accurate, the amount of broken corn is small, and the ability to remove bran is strong.

- Suitable for corn processing plants and feed mills of all sizes.

Russian customers come to the factory to visit the bean shelling machine

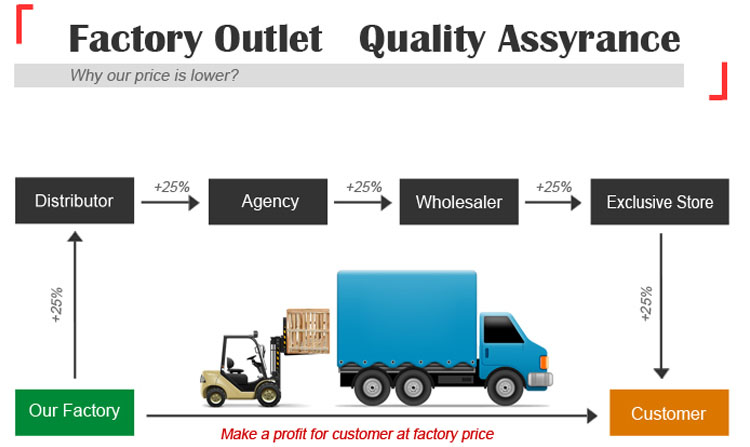

Why our bean shelling machine is low cost?

Customers and partners all over the world

-

1000kg small broad bean shelling machine soybean pea chickpea shelling machine lowest price

-

Masor Bean PeelerMasor Bean Peeler

-

MTPS Lentil Peeler Lentil Peeler

-

China Supplier Electric Garlic Peeler

-

Low Cost Corn Peeling Machine Corn Peeling Machine

-

dry jumbo white corn peeler 500kg/h hominy grits bianco crushing equipment purple/red corn peeler

-

White hominy yellow ground corn whole kernel peeling machine peeled maize for milling and food industry grits corn for extrusion

-

500kg/h corn peeler and degerminator

-

Automatic Dal Peeling Machine Urad Dal peeling machine

-

capacity 500kg/h Husk removing black bean peeling machine

Other Products

-

$500.00 / set

$500.00 / set -

$20000.00 / set

$20000.00 / set -

$400.00 / set

$400.00 / set -

$10000.00 / set

$10000.00 / set -

$900.00 / set

$900.00 / set -

$2250.00 / set

$2250.00 / set -

$400.00 / set

$400.00 / set -

$20000.00 / set

$20000.00 / set -

$899.00 / set

$899.00 / set -

$2000.00 / set

$2000.00 / set