Oil Test Separator Three Phase Separator ASME Pressure Vessel

-

Supplier: Shengli Oilfield Shengji Petroleum Equipment Co., Ltd. -

Region: Shandong, China -

Contact: Mr John zhou -

Price: $19500.00 /set -

Min. Order: 1 set

| Working temperature (℃): | 100-450℃ | Applicable industries: | Energy and Mining |

| Internal material: | SS | Place of origin: | Shandong Province, China (Mainland), Shandong Province, China |

| capacity: | request, demand | Core component warranty: | 1 year |

| Video outbound inspection: | if | Marketing type: | New product |

| color: | According to customer requirements | Mechanical test report: | if |

| Health status: | new, new | After-sales service provided: | Engineers can repair machinery overseas |

| Certification: | American Society of Mechanical Engineers | usage: | oilfield |

| Outer material: | SS | weight: | 3-50 tons, 3000 |

| Core components: | PLC, motor, pressure vessel | Moderate: | oil, gas, water |

| Design pressure (MPa): | 10 MPa | design standards: | American Society of Mechanical Engineers |

| Showroom location: | Egypt, United States, Uzbekistan | Volume (cubic meters): | 50 |

| Package preview: | payment terms: | L/C, D/A, D/A, wire transfer | |

| Dimensions (length*width*height): | According to customer needs | brand: | SJ,SJ |

| Packaging details: | Determine shipping method based on product size | Maximum working pressure (MPa): | 9 MPa |

| Warranty: | 2 years | Main selling points: | long lasting |

| Supply capacity: | 20 sets per month |

Shengji brand oil well test separator

Oil and gas well test separators are key equipment used in the oil and gas industry to separate and measure the oil, gas, and water produced by oil and gas wells. It plays an important role in determining the quality and quantity of hydrocarbons in the reservoir and helps in making informed decisions regarding field development strategies.

The emergence of oil and gas well testing separators dates back to the early 20th century, when the need to accurately measure and separate different production elements became apparent. Initially, basic separators were used, relying on gravity and simple mechanical mechanisms to achieve separation. However, with advances in technology and the need for more accurate results, modern oil and gas well testing separators have undergone significant evolution and are now highly sophisticated and efficient.

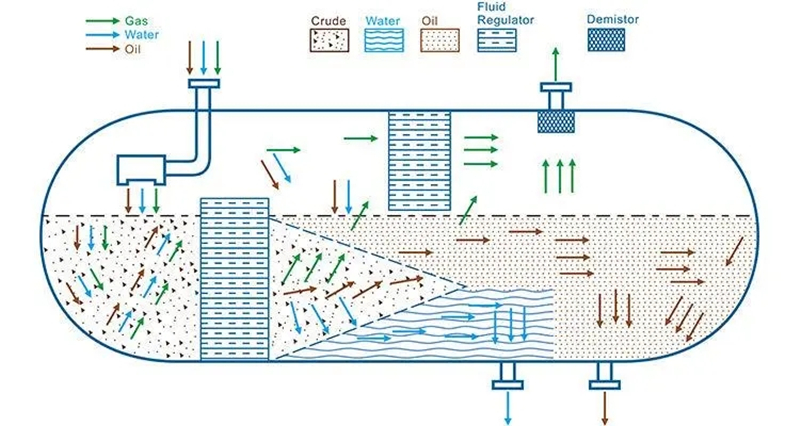

1. Working principle

The working principle of oil and gas well test separators revolves around the physical properties of the fluid in the well. These properties include density, surface tension, and viscosity. When well fluids enter the separator, they undergo a series of processes that facilitate separation. Separators rely on differences in density and surface tension of fluids to separate them into their individual components.

2. Components:

The Sanjack Well Test Separator consists of several integral components, each serving a specific purpose in the separation process. These components include:

1). Inlet Section: This section is designed to receive the well fluid and direct it into the separator for further processing.

2). Pre-separation section: responsible for the preliminary separation of a large amount of gas from the liquid phase. This part reduces the risk of gas entrapment, affecting the accuracy of the measurement.

3). Gravity Sedimentation Section: This section allows separation based on density differences of gas, oil and water. Give the fluid sufficient residence time to settle and collect the separated components from different outlets.

4). Coalescence part: This part is conducive to the separation of small droplets and gas phase. It utilizes coalescing materials or devices to merge smaller droplets into larger droplets, thus enhancing their separation.

5). Liquid and Gas Outlets: These outlets are used to collect the separated liquid and gas streams respectively. Install appropriate measuring equipment to determine the flow rate and composition of each stream.

3.Application

1). Reservoir Evaluation: Oil and gas well test separators play a vital role in evaluating reservoir productivity and quality. The measured data helps determine the potential size of the reservoir, the production of oil, gas and water, and the properties and behavior of the reservoir fluids.

2). Field Development Strategy: Data obtained from testing separators on oil and gas wells helps determine the best production strategy for a field. It helps make decisions about well spacing, production rates and placement of artificial lift systems.

3). Production Optimization: Separator data helps optimize production operations by identifying areas with potential problems, such as water or gas coning. This information allows the implementation of appropriate mitigation strategies.

4). Compliance and reporting: Oil and gas well testing separators provide accurate data, which is critical for compliance and reporting to relevant agencies. This ensures transparency in the oil and gas industry and helps meet legal obligations.

The oil and gas well test separator is an important tool in the oil and gas industry, which can accurately separate and measure the oil, gas and water produced by the oil and gas well. Its working principle and various components ensure reliable and valuable data for reservoir assessment, field development strategy, production optimization, compliance and reporting. As technology continues to advance, we can expect further advancements in oil and gas well testing separators, increasing their efficiency and capabilities in the oil and gas industry.

1). Sensitive to scaling;

2). Fast separation speed;

3). The control system is advanced, has a high degree of automation and is easy to operate;

4). Skid-mounted design facilitates lifting and transportation, saving transportation costs;

5). High security: small containers bring high security;

6). The structure design is compact and reasonable, integrating a variety of measuring instruments and control equipment;

7). Compatible with multiple control methods (direct+PLC+PC+DCS);

• High pressure test separator performance parameters

• Working pressure: 9.0 MPa

• Design pressure: 9.8 MPa

• Liquid handling capacity: 1000 m3/d

• Gas handling capacity: 60×104nanometer3/d

-

household lpg cooking gas tank

-

Hot sale stainless steel sanitary manhole cover food grade water tank round manhole cover

-

2 liter water pump pressure tank

-

Compressed Natural Gas Cylinders for Vehicles (CNG-1)

-

Complete and easy-to-operate LPG cylinder production line

-

China factory price 1000 gallon home propane tank

-

100m3 LPG storage tank liquefied petroleum gas tank manufacturer

-

Superior Manufacturer 100m3 Lpg Tank for LPG Gas Storage Tank iso tank container

-

25000 litres LPG gas skid refill stations with full set valves and LPG gas tank

-

lpg cooking gas filling station lpg filling plant for sale

Other Products

-

$20000.00 / set

$20000.00 / set -

$20000.00 / set

$20000.00 / set -

$1000.00 / piece

$1000.00 / piece -

$20000.00 / set

$20000.00 / set -

$20000.00 / set

$20000.00 / set -

$20000.00 / set

$20000.00 / set -

$20000.00 / set

$20000.00 / set -

$29700.00 / set

$29700.00 / set -

$32000.00 / set

$32000.00 / set -

$750000.00 / unit

$750000.00 / unit