Jet DRO ZX6350ZA drill bits for sale

-

Supplier: Tengzhou Hipow Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Mr James Wang -

Price: $4200.00 /set -

Min. Order: 1 set

| Name: | Cheap Jet DRO Drilling and Milling Machine ZX6350ZA for sale | Voltage: | 220/380/400/415V 50/60Hz |

| Year: | new | T-slot(mm): | March 14, 1970 |

| Main motor: | 2.2 kW | Face milling capability: | 25 mm |

| port: | Any port in China | brand: | Shipov |

| working desk size: | 1250*320mm | Drilling Capacity: | 50 mm |

| After-sales service provided: | Free spare parts, online support, video technical support | Supply capacity: | 100 units of cheap Jet DRO drilling and milling machine ZX6350ZA for sale every month |

| Warranty: | 1 year | Spindle taper: | ISO40 |

| Health status: | new | weight: | 1600 |

| Origin: | Shandong Province, China | Spindle taper: | ISO40 |

| Certification: | International Standard/CE | Packaging Details: | Machine Model: Cheap Jet DRO Drilling and Milling Machine ZX6350ZA For Sale Packaging Type: Plywood Box Packaging Size: 1680 * 1480 * 2150mm (one set per box) Net Weight / Gross Weight: 1600 KGS |

| type: | common | model: | Mid-engine |

| Spindle speed: | 60---1500 (vertical)/30---1300 (horizontal) | X/Y/Z rapid movement: | (8 steps) 15-370 |

| Dimensions (L*W*H): | 1680*1480*2150mm | Workbench travel (mm): | 1250*320mm |

| Whether CNC: | normal | payment terms: | L/C, T/T, Western Union |

| X/Y/Z axis travel: | 600/300/280 mm | strength: | 2200 |

|

Cheap Jet DRO Drilling and Milling Machine ZX6350ZA for sale |

|

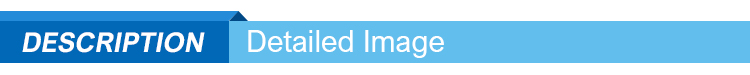

Key Features 1. The milling head has automatic drilling function and can rotate ±45 2. Universal milling machine has milling and tapping functions 3. The machine tool table adopts gear transmission power feed, 4.Full-featured and flexible 5. Universal milling machine can be equipped with plugs and rotating worktable 6. The working table and guide rails are made of supersonic high-frequency quenching 7. The workbench is made of HT200-250 high-strength cast iron 8. Dovetail groove workbench guide rails can withstand greater overturning moment 9.Vertical milling spindle automatic feed 10. Gear drive milling head

|

1.X/Y/Z three-axis automatic feeding

2.The machine can be equipped with a slotting head

1) Can install 100, 125mm mobile slotting head

3. This machine can be equipped with a dividing head

1) Can be installed with φ110mm, 125mm, 160mm semi-universal dividing heads

4.The machine tool can be equipped with vertical and horizontal rotary tables

1)φ250mmVertical and horizontal rotating table Can be installed

5.Combined control panel

1) DRO and switch are integrated on one panel, making the machine easy to operate.

2) X, Y, Z axis digital display optional

|

thing | Mid-engine |

Spindle taper | 7:24 ISO40 |

Maximum automatic feed drilling diameter (cast iron) (mm) | 8 |

Maximum manual drilling diameter (for cast iron) (mm) | 50 |

Maximum diameter of end milling cutter bar (mm) | twenty five |

Maximum drilling diameter | 120 mm |

Workbench size (mm) | 1250×320 |

Worktable travel (L/H/V) (mm) | t600/300/280 |

Distance from vertical spindle nose to worktable surface (mm) | 90---370 |

Horizontal spindle centerline to worktable surface (mm) | 0---280 |

Vertical spindle centerline to vertical guide rail (mm) | 200---550 |

Spindle speed range | (8 steps) 60---1500(V) / (12 steps) 30---1300(H) |

X, Y axis automatic feed (mm/min) | (8 steps) 15-370 |

Vertical axis travel (mm) | 120 |

Workbench T-slots (number/width/distance) (mm) | March 14, 1970 |

Main motor (Kw) | 1.5 (vertical) 2.2 (horizontal) |

Workbench automatic feeding motor power (W) | 750 |

Cooling pump motor (W) | 40 |

Dimensions | 1680×1480×2150 |

Net weight/gross weight (kg) | 1500/1600 |

-

Second-hand vertical turret milling machine light travel axis key training technology parts sales video factory second-hand

-

Supply 6325 Turret Mill with Ruler Mill

-

Universal milling machine turret type second-hand milling machine

-

UM1480 Made in China Universal Milling Machine / Rotary Head Universal Milling Machine

-

Factory direct sale low price high precision 3H universal milling vertical turret lathe milling machine price

-

High precision Taiwan turret head milling machine X6325 cheap price

-

Low price universal high precision second-hand turret milling machine motor provides universal milling machine medium-sized second-hand

-

Xk7121 CNC milling machine with tool changer Economical CNC milling machine

-

( Fresadoras de Torreta ) turret milling machine X6323A X6325 X6325D X6330A X6333

-

Double column gantry milling machine/plano miller/plano milling machine

Other Products

-

$3100.00 / set

$3100.00 / set -

$5000.00 / set

$5000.00 / set -

$6000.00 / set

$6000.00 / set