High Speed algae industrial centrifugal spray dryer with PLC control system for milk powder

-

Supplier: Sino Pharmaceutical Equipment Development (Liaoyang) Co., Ltd. -

Region: Liaoning, China -

Contact: Mr David H -

Price: $16000.00 /set -

Min. Order: 1 set

| After-sales Service Provided: | Online support,Video technical support,Free spare parts,Field installation, commissioning and training; | Voltage: | 380V; |

| Weight: | 1400kg; | Name: | SINOPED LPG-5 Model Small Scale Laboratory Pilot Lab Spray Dryer; |

| Discharge method: | Cyclone separator; | Package Type: | Export wooden case for Industrial centrifugal spray dryer; |

| Applicable Industries: | Food & Beverage Factory,Food Shop,Energy & Mining,Food & Beverage Shops,Advertising Company; | Single gross weight: | 1,000 KG; |

| Used Area: | Pharmaceutical Chemical Industry; | Selling Units: | Single item; |

| Warranty: | 1 Year; | Water evaporation capacity: | 5 kg/h; |

| Condition: | New; | Application: | Milk / Egg Yolk / Egg yellow; |

| Place of Origin: | China (Mainland); | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Certification: | CE ISO; | Dimension(L*W*H): | 1060x1200x2200mm; |

| Key Selling Points: | Automatic; | Raw material: | Powder; |

| Power(W): | 27kw; | Material: | Stainless Steel; |

| Package Preview: | https://sc02.alicdn.com/kf/HTB1UpmrXQH0gK0jSZFNq6xMqXXab.jpg_640x640.jpg,https://sc01.alicdn.com/kf/HTB1CBKsXND1gK0jSZFyq6AiOVXac.jpg_640x640.jpg; | Outlet air tempetature: | 80~90C; |

| Inlet air tempetature: | 140~350C adjustable; | Type: | Spray Drying Equipment; |

| Brand Name: | SINOPED; | Application: | Medicine Processing,Chemicals Processing,Food Processing; |

| Single package size: | 176X141X249 cm; |

High Speed algae industrial centrifugal spray dryer

with PLC control system for milk powder

Product Application

High Speed algae industrial centrifugal spray dryer with PLC control system for milk powder is a technology most widely used in the liquid technology shaping and in the drying industry. The drying technology is most suitable for producing solid powder or particle products from liquid materials, such as solution , emulsion, suspension and pumpable paste states, For this reason, when the particle size and distribution of the final products, residual water contents, mass density and the particle shape must meet the precise standard, spray drying is one of the most desired technologies.

water

feed pump-------- →centrifugal spray atomizer

slurry ↓

high-efficiency air filter → drying chamber

↑ ↓

Electrical heater cyclone → finish product

↑ ↓

Steam exchanger suction fan

↑ ↓

blower spray dust catcher

↑ ↓

Elementary and middle exhaust emission

efficiency air filter

Original liquid would be feed by Peristaltic Pump frm vessel, and become spray with help of High Speed Atomizer, the atomizer would be driven by Compressed Air. Atomizing Disc diameter can be reac 25000 rpm at most. Peristaltic Pump can be adjusted and stable, which can ensure Feeding Stably and Control Temperature effectively.

The new air would be filtered by Pre-filter and Mid-filter, then start to be heated by Electricity, until inlet air temp. reach above 300C(Depend on actual need). At this moment, the heater air would be enter the spray chamber uniformly, with the help of Spirl-type Hot-ait Distributor on the cover. After hot air touch with Spray Dryer materials, water can be evaported very fast, fine and dryer powder can be collected by cylone separator.

Atomizer is the most important accessory in spray drying machine, it is used for changing LIQUID status into SPRAY status at a high speed rotation motions, usually can reach 18000~25000 rpm, Our company has adopt Chinese Specilalzied Supplier, can ensure customers for 2 years warranty period.

LPG Spray Dryer have adopt quick connection, easy to maintain, top tight fittings

Why choose us?

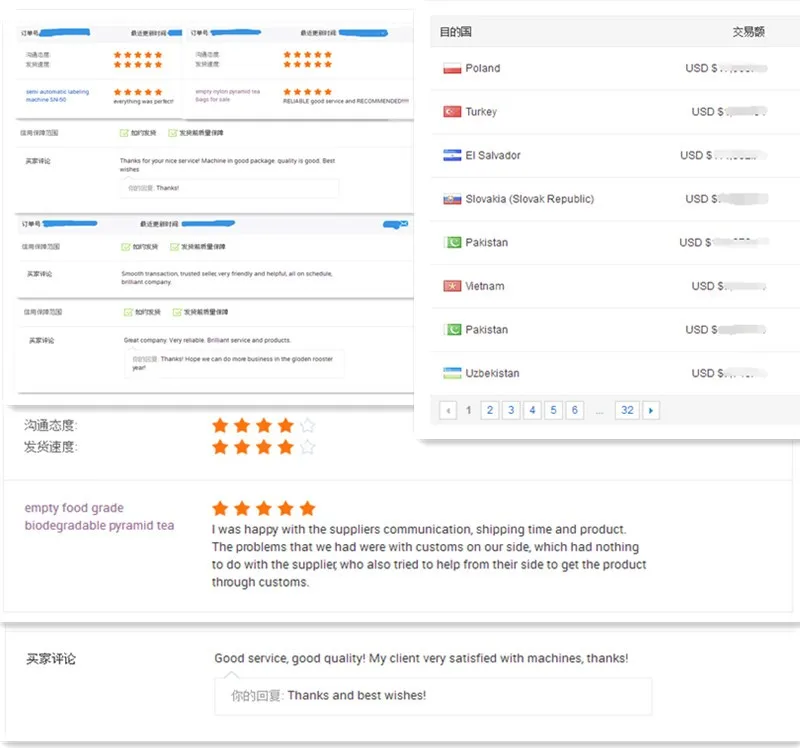

1. SINOPED has been engaged in the purification technology and application. And we have the R&D team, performing continuous product research and improvement from time to time.

2. Our products are certificated by the most prestigious national and international institutes.

3. Each procedure of the production process is conducting under the strict quality control system. Our QC inspects each lot of the incoming material and the finished products carefully, so that we can supply the best products for customers.

4. From the design to the producing, each procedure is controlled strictly, so we can control the product costs optimally, and offer products with the best quality and the most competitive price. Win-win is our ultimate purpose.

One-year warranty period for whole machine except of tubes and human factors etc, and 12-month of after-sale service from the date when you receive machine or 12 months when installation finished;

Consultant services for whole machine life, and 24 hours technical support by email;

UPS, English software, user manual and the installation & debugging by our experienced technicians.

1. Can your machine meet our need well?

We will supply you a proposal as to your specific requirement, and each machine is customized to satisfy customer's need well.

2. Are you a factory or a trading company?

We are the manufacturer, and have been in industry for more than ten years.

3. What's your payment way?

T/T by our bank account directly, or by Alibaba's trade assurance service, or by the West Union, or in cash.

4. How can you ensure the machine's quality after we put the order?

Before the delivery, we will send you machine's pictures and videos, or you can come to us to have the quality checking by yourself, or by the third party inspection organization contacted by your side.

5. We are afraid you won't deliver us the machine after we pay you the money.

Please note our above business license and certificates. And if you don't trust us, you can use Alibaba's trade assurance service or by LC.

6. Why choose your company?

We have been engaged in the manufacturing of various packing machines professionally over 10 years, and we can provide better after-sales service.

Sino Pharmaceutical Equipment Development (Liaoyang) Co., Ltd. (SINOPED) is a professional manufacturer and supplier of pharmaceutical and chemical machinery and equipment in China. We belong to SINOPEC International Group.

We have a well-experienced team to manufacture pharmaceutical machinery and equipments and a professional design institute. With rich experiences in pharmaceutical machinery and equipment field and numbers of professional engineers, we have designed and developed many types of machinery and equipments including clean room project, soft-gel production line, glass-lined reactor, fermentor, centrifuge, granulator, mixer, dryers, pulverizer, tablet press, soft and hard blister packing machine, capsule filling machines, cartoner and rollers, etc.

Due to our good credit and service, , we have made great achievements in the past years. We have established long-term business relations with many customers and some of our overseas customers have appointed us to be their purchase agency in China. Our products are exported to many countries & areas, such as Korea, India, Indonesia, Pakistan, Thailand, Vietnam, Iran, Japan, Denmark, Romania, Bulgaria, Russia, South Africa, Nigeria, the USA, Australia, Canada, Argentina and Chile. Besides machinery and equipment, we also supply production lines and turn key projects.

In SINOPED you can get your desired goods with the best prices and good quality. Welcome your enquiries from all over the world.

-

Best quality 10kg 15kg freeze dryer food drying freeze dryer price household oil-free vacuum pump usa ready stock

-

Vacuum freeze dryer price

-

Household 6kg 8kg fruit food mini vacuum drying household freeze dryer freeze dryer with vacuum pump machine US spot

-

Mini Vacuum Freeze Dryer For Sale

-

Digital Display Multifunctional Combination 8 in 1 Heat Press Machine Sublimation Printing T-shirt Cup Tray Hat Printing

-

Vacuum drying machine, milk powder for vacuum drying

-

Factory price mini industrial vacuum food freeze dryer price

-

220V / 110V Household Professional Food Dehydrator Fruit Dryer

-

Stainless Steel Vacuum Chamber Vacuum Degassing Chamber Glass Cover Silicone for Evacuating and Protecting Food

-

2019 China Laboratory Industrial Small Freeze Dryer Price For Sale

Other Products

-

$1899.00 - $2399.00 / set

$1899.00 - $2399.00 / set -

$1500.00 - $1600.00 / set

$1500.00 - $1600.00 / set -

$31380.00 / set

$31380.00 / set -

$3300.00 / set

$3300.00 / set