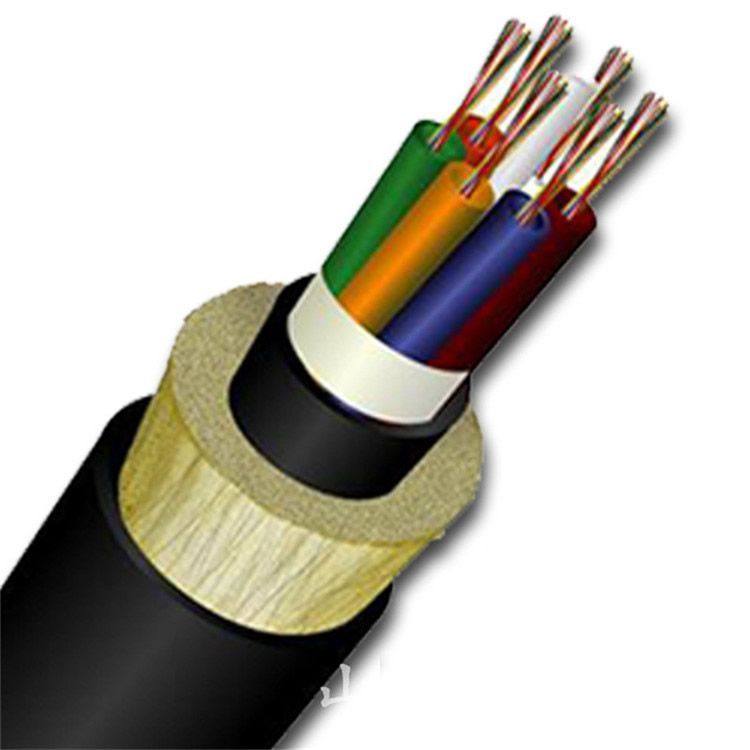

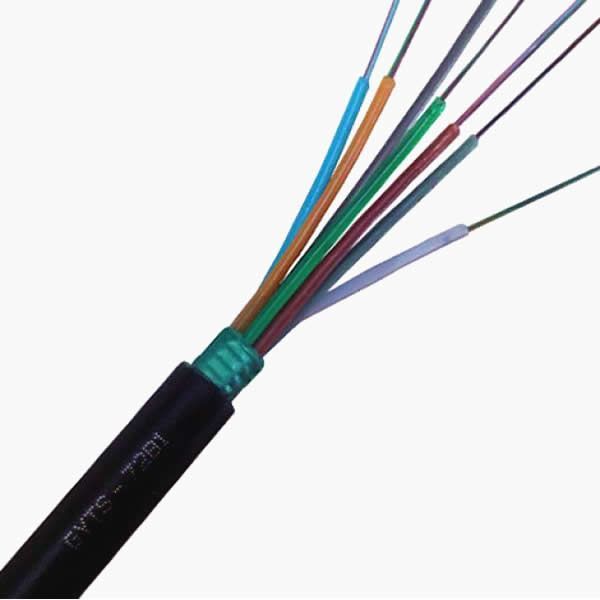

Outdoor Cable 48-Core 8-Core 24-Core 2-Fiber Cable Communication Armouring 12-Core 6-Core Buried Optical Cable

-

Supplier: QuFuLitelai, electric power equipment co., LTD -

Region: Shandong, China -

Contact: Ms Tongtong Kong -

Price: $1.00 / 1000 - 9999 meters

$0.90 / >=10000 meters -

Min. Order: 1000 meters

Introduction

All-dielectric self-supporting optical cables are made entirely of dielectric materials and contain the necessary support systems. They can be directly hung on non-metallic optical cables on power towers.

sheath

PE sheath: ordinary polyethylene sheath. Used for power lines below 110KV.

AT sheath: Anti-tracking sheath. Used for power lines above 110KV. Required support systems and non-metallic fiber optic cables that can be hung directly from power towers.

feature

(1) Specifically designed for power systems, it is a fully insulated self-supporting overhead optical cable, and the structure does not contain any metal materials;

(2) Fully insulated structure with high voltage resistance index, which is conducive to live installation and construction of overhead power lines without affecting the operation of the lines;

(3) Use anti-fiber materials with high tensile strength, which can withstand strong tensile forces, meet the requirements of large spans of overhead power lines, and can prevent birds from pecking and people from shooting;

(4) The thermal expansion coefficient of ADSS optical cable is small. When the temperature changes greatly, the curvature of the optical cable line changes very little, and it is light in weight and is less affected by ice and wind loads.

Advantages

The national standards for ordinary optical cables clearly stipulate the mechanical strength that optical cables used in different ways (such as aerial, pipeline, direct burial, etc.) should have. ADSS optical cable is a self-supporting overhead optical cable, so it not only has to withstand the long-term effects of its own gravity, but also the baptism of the natural environment. If the mechanical performance design of the ADSS optical cable is unreasonable and does not adapt to the local climate, the optical cable will have safety hazards and its lifespan will be reduced. Therefore, each ADSS optical cable project must be designed according to the natural environment and span of the optical cable wiring. The installation span of ADSS optical cable can reach 1800 meters per section, and it has high voltage resistance, good resistance to electrical corrosion, and lightning protection. It can be laid on transmission line poles and towers with a voltage level of 500kV. It has strong resistance to gunfire. Generally, it can be shot with a sand gun at a distance of 10 meters without causing any damage to the cable. It has strong low temperature resistance and strong environmental adaptability. Optical cables are laid independently without relying on transmission lines, making construction and maintenance easy and without the need for power outages. Optical cables are also relatively cheap. It also has strong low-temperature resistance and environmental adaptability. Optical cables are laid independently without relying on transmission lines. Construction and maintenance are convenient, no power outages are required, and optical cable prices are relatively cheap. It also has strong low-temperature resistance and environmental adaptability. Optical cables are laid independently without relying on transmission lines. Construction and maintenance are convenient, no power outages are required, and optical cable prices are relatively cheap.

Ordering instructions

a. It is necessary to provide usage scenarios, such as mountains and forests, river crossings, bridges, underwater, pipelines, wind farms, etc.

b. Design requirements such as core number, model, span, sheath material requirements, etc. need to be provided

c. Please provide the required optical cable type, including central tube structure and layered structure

d. If customization is required, other known detailed technical parameters or design drawings must be provided

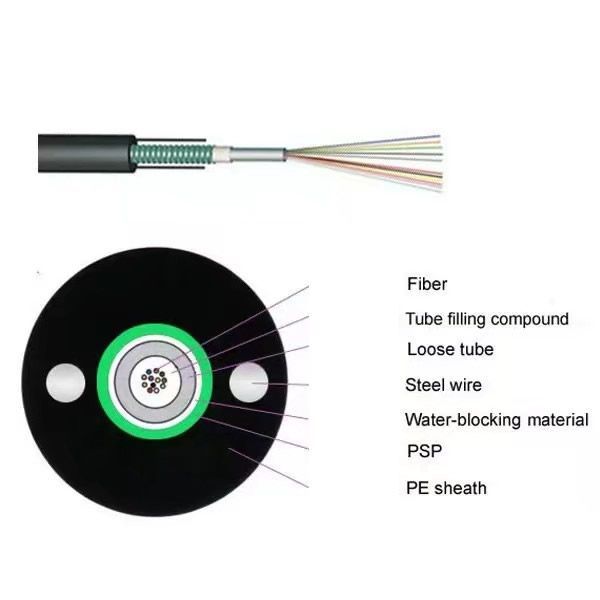

ADSS optical cable model and filling diagram

-

OPGW optical fiber ground wire 24 core fiber optic cable

-

GHT PVC 100/305m UTP RJ45 Cat7 Cat5e Cat 5 5e 6 7 8 Cable Path Line Network Cable Lan Ethernet Cable

-

Band 42 Lte Tp Link Price Bd Lower Corner Ethernet Cat6 Cable Cca Cu Cmr 24awg 28awg UTP Cat6e UTP Cat6 Cable

-

guangzhou factory price indoor ethernet cable cat6 utp cable

-

New Product Transparent Bare Fiber Indoor Invisible Fiber Fiber to the Room

-

OEM LOGO 305m Box UTP FTP SFTP Cat 5E 6A 6 Cable Cat5E Cat6A Cat6 Ethernet Cable Network Lan

-

LC-LC OM3 Fiber Patch Cable Fiber Optic Equipment with Competitive Price

-

GYTA53 12-core 24-core outdoor direct buried loose tube double G652D single-mode armored optical fiber cable

-

Factory supply high performance KX6 cctv cable kx6 kx7 coaxial cable for cable television cctv communication

-

RG59 Coaxial Cable 2C RG59 Cable With Power CCTV Cable

Other Products

-

$2.40 - $2.50 / set

$2.40 - $2.50 / set -

$1.40 - $1.50 / set

$1.40 - $1.50 / set -

$1.40 - $1.50 / set

$1.40 - $1.50 / set -

$1.40 - $1.50 / set

$1.40 - $1.50 / set -

$0.90 - $1.00 / meter

$0.90 - $1.00 / meter -

$0.90 - $1.00 / meter

$0.90 - $1.00 / meter