High quality 630-1000mm hot melt hydraulic butt welding machine

-

Supplier: Hebei Boda Plastic Technology Co., Ltd. -

Region: Hebei, China -

Contact: Mr David Xue -

Price: $24500.00 /set -

Min. Order: 1 set

Product details

| Health Condition: | New | Welding materials: | Polyethylene High-density polyethylene Polypropylene Polyvinylidene fluoride |

| Power (kW): | 24 kW | strength: | 24 kW |

| Welding area: | 630-1000 mm | weight: | 2600 |

| Input Voltage: | AC 380V | Marketing Type: | Hot Products of 2023 |

| use: | Welding plastic pipes | Function: | Welding plastic pipes |

| Welding Type: | Hydraulic butt welding machine | Origin: | Hebei, China |

| Video factory inspection: | if | frequency: | 50 Hz |

| application: | Plastic pipe hot melt welding machine | Applicable industries: | Building material stores, machinery repair shops, manufacturing plants, retail, construction engineering |

| aspect: | 630-1000 mm | Packaging Details: | Plywood Box |

| Pipe Diameter: | 630-1000 mm | Gross weight per piece: | 2600.000 kg |

| Warranty: | 2 years | Certificate: | CE |

| Package Preview: | Exhibition Hall Location: | Brazil, Peru, Indonesia, Pakistan, Morocco, South Africa, Nigeria | |

| pack: | Wooden box | Sales Unit: | Single item |

| Voltage: | 380 | Single packing size: | 95X68X68 cm |

| Weight (kg): | 2600 kg | Brand Name: | MM-Technology |

| Key selling points: | Easy to operate | Core components: | PLC |

| After warranty service: | Video Technical Support Online Support | Core component warranty: | 2 years |

| Mechanical test report: | if |

High quality 630-1000mm hot melt hydraulic butt welding machine

describe

SWT-V1000H is a hydraulic butt fusion welding machine. It is used to butt weld pipes and fittings such as elbows, tees, Y-pieces and flange necks by simply adjusting the clamp tie rod without any additional equipment.

It is suitable for welding HDPE, PP, PVDF and other plastic pipes and fittings.

It is suitable for welding HDPE, PP, PVDF and other plastic pipes and fittings.

It consists of a frame, a hydraulic device, a planer, a heating plate, a planer and heating plate bracket, optional parts, etc.

Removable PTFE-coated heating plate with high-precision temperature control system;

Electrical planning tool with safety limit switches to avoid accidental start-up. (optional)

Made of lightweight and high-strength material; specially designed clamp opening angle is 45°

The low starting pressure ensures reliable welding quality for small pipes.

The welding position can be changed, making it easier to weld various pipe fittings.

Independent dual-channel timers display the time for the soaking and cooling stages respectively, and an alarm will sound when the timer expires.

High-precision, shock-proof pressure gauge for clearer readings.

Digital pressure gauge installed on the machine

Removable PTFE-coated heating plate with high-precision temperature control system;

Electrical planning tool with safety limit switches to avoid accidental start-up. (optional)

Made of lightweight and high-strength material; specially designed clamp opening angle is 45°

The low starting pressure ensures reliable welding quality for small pipes.

The welding position can be changed, making it easier to weld various pipe fittings.

Independent dual-channel timers display the time for the soaking and cooling stages respectively, and an alarm will sound when the timer expires.

High-precision, shock-proof pressure gauge for clearer readings.

Digital pressure gauge installed on the machine

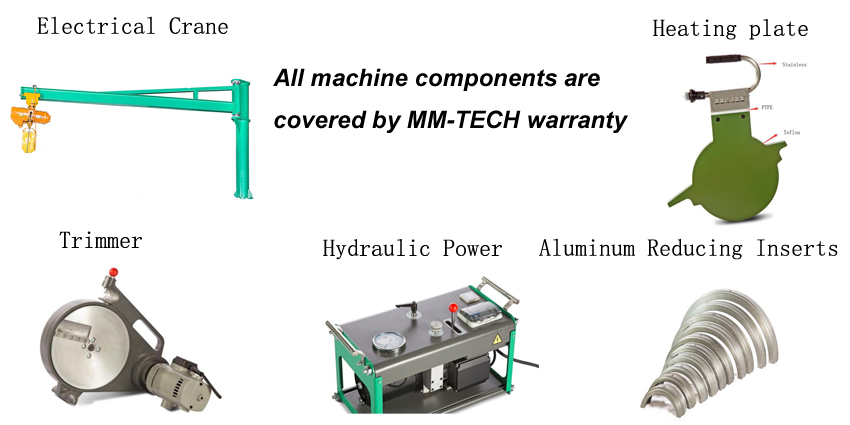

V1000 includes:

* One machine body is equipped with 4 clamps and 2 hydraulic cylinders with quick connectors;

*Teflon-coated heating plate with separate temperature control system;

*Self-disassembly device: helps to disassemble the heating plate after the soaking process;

* An electric milling cutter;

* Hydraulic hose with quick connector;

*Supports milling cutter and heating plate.

*Teflon-coated heating plate with separate temperature control system;

*Self-disassembly device: helps to disassemble the heating plate after the soaking process;

* An electric milling cutter;

* Hydraulic hose with quick connector;

*Supports milling cutter and heating plate.

Available options:

Data Logger

Support roller

Short tube end holder

Electric crane

Fuselage car

Different blades (single blade, ISO blade)

Support roller

Short tube end holder

Electric crane

Fuselage car

Different blades (single blade, ISO blade)

parameter

Welding range | 630mm~1000mm |

Reducing inserts | 630mm-710mm-800mm-900mm-1000mm |

Application | PE, PP and PVDF |

Operating voltage | ~380V±10%,50/60Hz |

Total Power | 22.7 kW |

Planning Tools | 3 kW |

Heating Plate | 17.5 kW |

Hydraulic unit motor | 2.2 kW |

Ambient temperature | -10°~45° |

Why Choose Us

Product quality is guaranteed

Professional team quality service

Perfect after-sales service to solve your worries

application

Applications of hot-melt welded polyethylene pipes:

Hydraulic butt welding machines are suitable for welding plastic pipes and fittings made of PE, PP and PVDF.

Automatic butt welding machine can be operated under any complex working conditions.

Thermofusion welding machines weld HDPE, PP pipes and fittings for conveying gas, water and other fluids.

Automatic butt welding machine can be operated under any complex working conditions.

Thermofusion welding machines weld HDPE, PP pipes and fittings for conveying gas, water and other fluids.

Construction Site

VIEW MORE

You may like

-

Hydraulic HDPE pipe butt welding machineHDPE butt welding machine 315mm hydraulic butt welding machine

-

High-efficiency in-pipe cladding machine

-

PPR pipe hot melt machine

-

40mm-250mm plastic pipe welding machine HDPE pipe butt welding machine

-

DAJING Customizable simple style ppr pipe welding machine for ppr pvc pipe

-

Magnetic Orbital Welding Machine and MIG 500A Power Supply

-

Orbital welding machine for pipe welding automatic orbital pipe welding machine

-

ppr pipe hot melt welding machine with best price

-

Most Valuable 20-63mm PPR Dual Insulator Welding Machine

-

20-63mm Socket Welder for Ppr Pipe Socket Welder

Other Products

-

$3520.00 / set

$3520.00 / set -

$1980.00 / set

$1980.00 / set -

$1800.00 / set

$1800.00 / set

Related Search

hydraul butt fusion machin suppliers

new hot butt welding machine

hot melt applicator adhesive coating machine

electrofusion butt welding machines suppliers

automatic bandsaw blade flash butt welding machine

electric bandsaw blade flash butt welding machine

butt welding machine price suppliers

butt welding machine electric

butt weld machines

manual wire butt welding machine