High-efficiency in-pipe cladding machine

-

Supplier: Wincoo Engineering Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Jackie Nie -

Price: -

Min. Order: 1 piece

Product details

Product overview

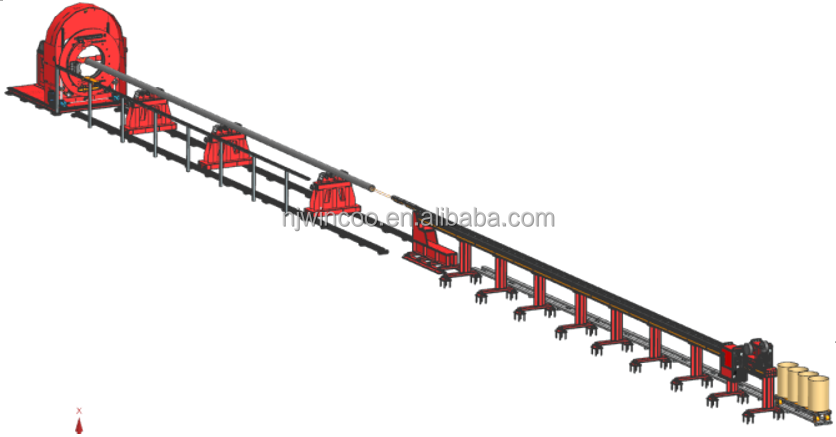

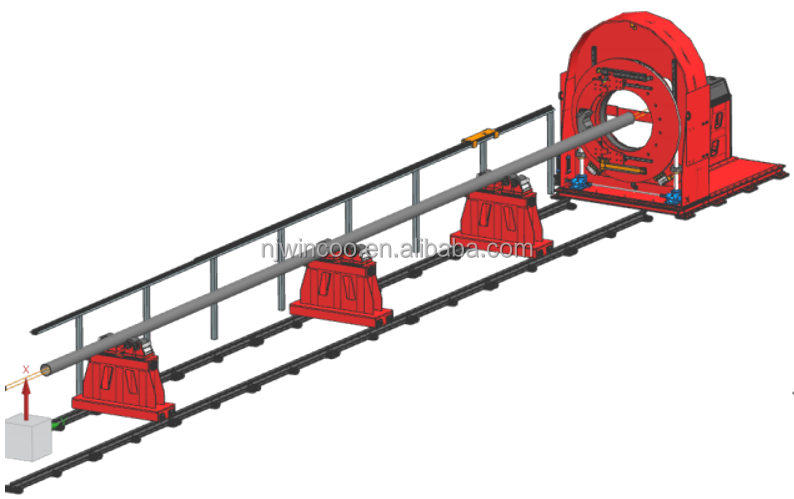

This equipment is mainly used for welding anti-corrosion materials on the inner wall of 12m long pipes. The welded pipes are rotated by the hollow chuck at the end. The welding gun pulls and guides the equipment through the wire rope to position and complete the welding into the channel.

The equipment consists of welding power source, welding head, machine head transmission and guidance system, hollow chuck head frame, roller frame, electrical control system, water cooling system, etc.

The equipment consists of welding power source, welding head, machine head transmission and guidance system, hollow chuck head frame, roller frame, electrical control system, water cooling system, etc.

Technical parameters

1 | Power supply type | DC inverter |

2 | welding current Working cycle (40℃) | 5~450A 450A 80%; 420A 100% |

3 | Hot wire current Working cycle (40℃) | 5~200A 200A 25%; 150A 60%; 140A 100%. |

4 | open circuit voltage | 80V |

5 | input voltage | 3×400V (-25%+20%) 50/60Hz |

6 | Input power | 60 kVA |

7 | Frequency conversion cooling | air cooling |

8 | exhibit | 5.7” touch screen handheld interface / 17-inch screen industrial computer on the control cabinet |

9 | Data setting method | Touch screen settings |

10 | fault detection | Workpiece short circuit, over-temperature protection, over-current protection, over-voltage protection, water shortage protection, air shortage protection, power outage, power outage. |

11 | torch | Double torch, independent external constant temperature circulating water cooling, with chiller |

12 | Cooling water volume | 6L*4 sets |

13 | manufacturing standards | GB15579-2004 |

14 | Insulation safety level | H/IP23 |

15 | Cladding capacity | Outer diameter: Φ200~Φ850mm Thickness: 80mm Length: 12000mm |

16 | Superimposed driving speed | up to 650 mm/min |

No. 17 | Wire feed speed | Up to 5M/min |

18 | Deposit interest rate (2torches) | Maximum 4.8 kg/hour, can operate stably for a long time. Capacity up to 10 kg/hour |

19 | AVC accuracy | ±0.3V |

20 | Recommended peak current | 150~280A |

twenty one | Recommended base current | 100~200A |

twenty two | Recommended voltage | 8~16V |

twenty three | Tungsten diameter | 4.0/4.8mm |

twenty four | Wire diameter & spool size | 1.2 mm Max 50kg ISO 544 S760L spool (Φ760xW285xC400mm) and 250kg drum (Φ510xH820mm) |

25 | Single layer thickness | 1~3mm |

26 | Recommended gas flow | 12~20 liters/minute |

No. 27 | arc starting | High frequency/contact |

28 | Deposit interest rate | For 1.2mm diameter welding wire, 1~2kg/h per welding torch |

29 | load capacity | 10 tons with rollers |

Main components

1. Mechanical system

1. The welding gun mechanism and the welding power supply system as a whole can walk on the main frame, which can effectively shorten the length of the welding gun cable and ensure the stability of the equipment.

2. The welding gun head is installed on the guide rail, and the welding gun can move up and down through the push rod controlled by PID.

3. The welding gun has an automatic arc voltage tracking function. When the welding gun deviates from the welding surface, it can be adjusted and corrected in time.

4. The welding gun is cooled by forced circulating water and can be continuously welded for a long time.

5. Precision rotary mechanism (8Ton).

6. The height of the steel roller frame is adjustable.

2. AVC system

The AVC system uses stepper motors and linear guide designs. The stepper motor uses water circulation cooling to ensure long-term operation and stability.

The action of the stepper motor and arc voltage are controlled by PID program to ensure the stability of arc control. This feature is field proven and state of the art arc technology. See the image below for information about this device.

three. Surfacing cladding surveillance camera

Water-cooled welding camera system with TCP/IP communication protocol. A flashlight and a camera.

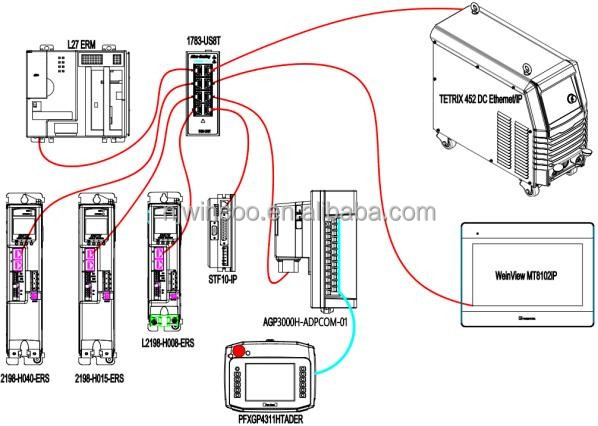

Four. control system

i-CLAD PCS 200 is a welding control system designed and manufactured by WINCOO using the world's most advanced technology. The system is controlled by the American Rockwell AB PLC system and combines WINCOO's development and manufacturing experience. It has advanced and digital features. , easy operation, intelligence, versatility, reliability and other characteristics. The operating system centrally sets, stores, and controls distributed synchronization, and the welding function parameters have good scalability.

Four. water cooling system

The water cooling device is equipped with XCW-5200AH forced water cooling circulation system to meet the needs of long-term continuous operation. Electronic temperature control is used to control the temperature range and display the set temperature and actual temperature digitally. Configure water quality filter. It has water flow detection and outputs alarm signal.

Detailed description

conditions and environment

This welding system is suitable for meeting the following conditions:

- Usage environment: Input power: 380V x 10%, AC, 50Hz x 1

- Ambient temperature: -10℃~45℃

- Relative humidity: 85% at 30℃

- Compressed air: 0.4 to 0.8Mpa

application

- Workpiece diameter: outer diameter φ200-φ850mm.

- Workpiece length: maximum 12000mm

- Workpiece wall thickness: 80mm

- Workpiece weight: maximum 10t

- Pipe material: API 5L Gr.B, X52, X60, X65, stainless steel, CrMosteel, etc.

- Wire materials and specifications: ERNiCrMo-3, ERNiFeCr-1, ER316L, ER2209, ERCCoCr-E, ERCCoCr-A, ERNi1, ERCuNi wire diameter 1.2mm;

- Groove form: Inner wall welding without groove

- Bevel pairing: None;

- Welding position: 1G position welding (the welding gun does not move, the workpiece rotates)

- Welding method: hot wire TIG

- Preheating requirements: According to the welding process, the system is not equipped with a preheating system.

- Welding layer inspection requirements: 100% UT delamination/100% PT

- Typical workpieces: hot-rolled steel pipes, seamless steel pipes, forged pipes, etc.

Construction site photos

VIEW MORE

You may like

-

Hydraulic HDPE pipe butt welding machineHDPE butt welding machine 315mm hydraulic butt welding machine

-

High quality 630-1000mm hot melt hydraulic butt welding machine

-

PPR pipe hot melt machine

-

40mm-250mm plastic pipe welding machine HDPE pipe butt welding machine

-

DAJING Customizable simple style ppr pipe welding machine for ppr pvc pipe

-

Magnetic Orbital Welding Machine and MIG 500A Power Supply

-

Orbital welding machine for pipe welding automatic orbital pipe welding machine

-

ppr pipe hot melt welding machine with best price

-

Most Valuable 20-63mm PPR Dual Insulator Welding Machine

-

20-63mm Socket Welder for Ppr Pipe Socket Welder

Other Products

-

-

$5000.00 / unit

$5000.00 / unit -

$30000.00 / set

$30000.00 / set -

$4000.00 / set

$4000.00 / set

Related Search

high efficiency electric poultry plucker machine

high efficiency quilting sewing machine

high efficiency candle machine

high efficiency gw40 bending machines

high efficiency self adhesive machine suppliers

high efficiency carbon black briquettes making machine

pipe bending machine

pipe welding machine

pipe cutting machine

automatic pipe welding machine