WDW Series 10kn to 600kn Computer Automatic Electronic Universal Tensile Material Testing Equipment Price

-

Supplier: Jinan Hensgrand Instrument Co., Ltd. -

Region: Shandong, China -

Contact: Ms Lucy Sheng -

Price: $4000.00 /set -

Min. Order: 1 set

| Supply Ability: | 300 Set/Sets per Month Material testing equipment; | Test range: | 2%-100% FS; |

| Weight: | 650kg; | Function: | tensile compression, bending,. shear test, etc; |

| Dimension: | 1045*545*1325mm; | Power supply: | 220v, 50/60hz; |

| Standard: | ASTM ISO EN JS; | Accuracy: | 1 Grade/0.5 Grade; |

| Brand Name: | HST; | Packaging Detail: | Standard exporting plywood case; |

| Place of Origin: | Shandong China; | Certificate: | CE ISO; |

| Model Number: | WDW; | Product name: | Material testing equipment; |

| Port: | Qingdao; | Warranty: | 12 Months; |

| Payment Terms: | L/C,T/T,Western Union; | Power: | Electronic; |

WDW Series 10kn to 600kn Computer Automatic Electronic Universal Tensile Material Testing Equipment Price

Application: Material testing equipment

WDW series Electronic Universal Material Testing Equipment Price is suitable for wide

range of material for tensile, compression, bending, split, cut, torn, punctured, burst, yield strength, elongation, nonproportional strength, modulus of elasticity, and other parameters.

Test Material: Material testing equipment

It is for metal, rubber, plastic, spring, textile, rope, glass and other composite materials testing.

It applies to aerospace industry, engineering inspection, university and college, iron and steel industry, research institution and other fields.Computer automatic control machine rise,

fall, test and stop etc. Easy operation, stable performance.

Technical parameter: Electronic Universal Material Tensile Testing Equipment Price

Model | WDW-20 | WDW-30 | WDW-50 | WDW-100 | WDW-200/ 300 | WDW-500/ 600 | |||

Max. Load | 20kN | 30KN | 50KN | 100kN | 200kN | 300kN | 500kN | 600kN | |

Structure | Four-column Floor Type (upper is compression and lower is tensile) | ||||||||

Control model | Constant stress, constant strain,constant displacement closedloop control System | ||||||||

Load accuracy | 1 class/ 0.5 class optional | ||||||||

Load range | 2%-100% of full scale /0.4%-100% optional | ||||||||

Load resolution | 1/300000 | ||||||||

Deformation test range | 2%~100% | ||||||||

Deformation accuracy | ≤±1% | ||||||||

Displacement accuracy | ≤±1% | ||||||||

Disp. resolution | 0.04um | ||||||||

Displacement speed | 0.05-1000mm/min | 0.05-200mm/min | |||||||

Tensile space | 600mm | 700mm | 550mm | 700mm | |||||

Compression space | 600mm | 700mm | 550mm | 700mm | |||||

Test width | 400mm | 450mm | 600mm | 650mm | |||||

Clamp way | Manual clamp / Hydraulic clamp (optional) | Hydraulic clamp | |||||||

Load Cell Configuration | One(max load), more load cells can be added according to customer requirement | ||||||||

Extend configuration | Large deformation extensometer, high or low temperature teste chamber, high temperature oven | ||||||||

Power supply | AC220/380V±10%,50Hz (can be customized) | ||||||||

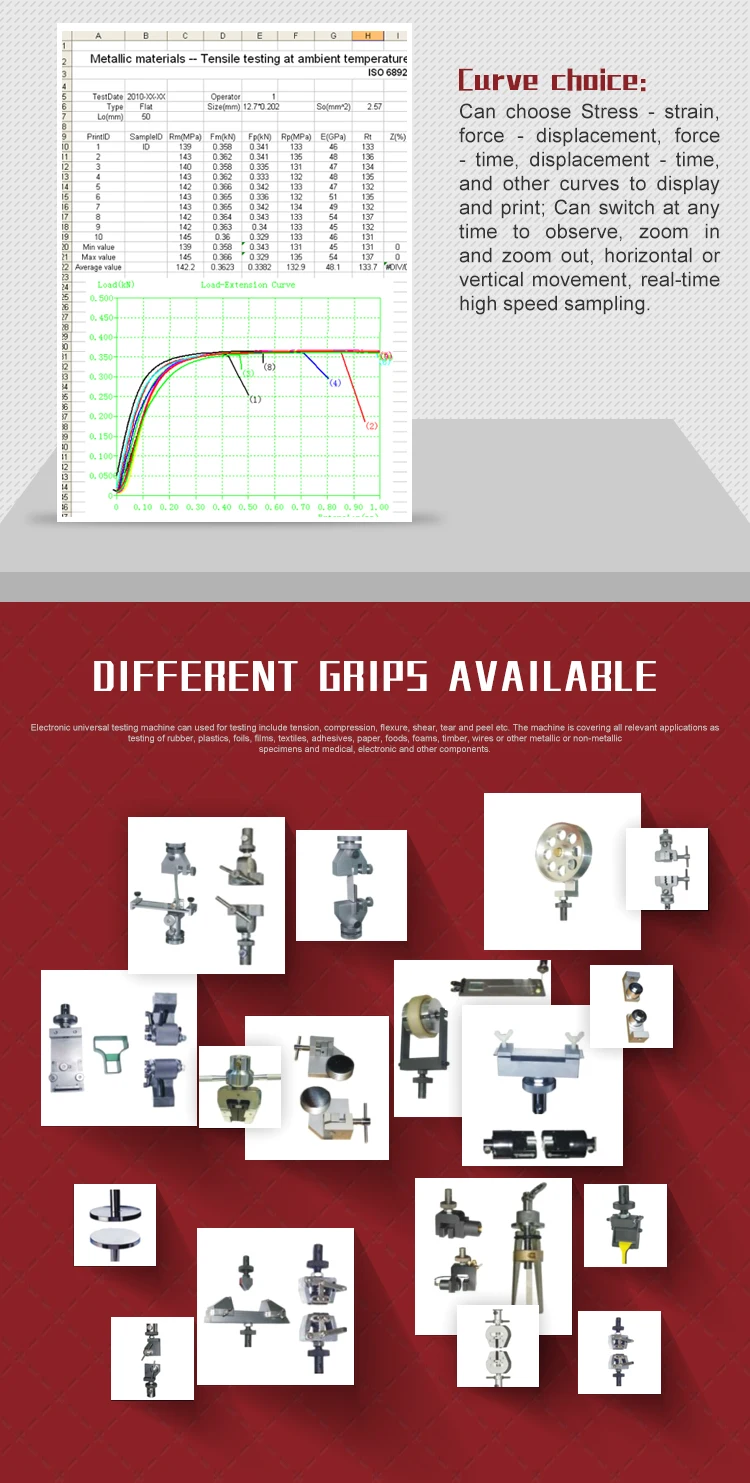

Features

1.High accuracy servo motor to control test speed.

2.Ball screw no backlash to guarantee the low noise and high driving efficiency

3.High accuracy load cell to measure the test load

4.High accuracy photoelectric encoder to measure the displacement.

5.Max test software has strong function, it can show test load, displacement, test speed,

test status, and also has the function of peak load holding, peak displacement holding

and self return original position.

6.Thousands of test fixture can be used according to different test request;

7.Compact structure with easy operation.

8.Limit switch and setting in the software to guarantee the safety

-

2 in 1 Laptop Motherboard DDR4 DDR3 Memory Slot Memory LED Diagnostic Analyzer Test Card

-

High Strength Compression Tear Testing Machine Universal Material Testing Machine Mechanical Tensile Testing Machine

-

Programmable Environmental Climate Chamber Humidity Temperature Test Chamber Climate Temperature Test Chamber Humidity Test Equipment Price

-

Faro Focus S350 3D Laser Scanner w/ Accessories, Case And Extra Batteries

-

Geophysical Transient Electromagnetic Sounder TDEM Equipment with GPS

-

Digital clamp multimeter high-precision clamp meter to measure voltage and current clamp multimeter DT266

-

1AC-D non-contact electric measuring pen 90-1000V induction electric pen electroscope electrician electricity indicator

-

Home Delivery Promotion Thermo Scientific-Niton DXL-XRF Precious Metals Analyzer

-

Best Price X-ray Fluorescence Spectrometer Metal Element Testing Handheld XRF Explorer 5000 EXP5000 Analyzer

-

2022 best-selling transparent electric screwdriver test pen multi-functional induction test pen

Other Products

-

$119.00 - $189.00 / set

$119.00 - $189.00 / set -

$550.00 / set

$550.00 / set -

$4400.00 / set

$4400.00 / set -

$130.00 / set

$130.00 / set -

$600.00 / set

$600.00 / set -

$600.00 / set

$600.00 / set -

$500.00 / set

$500.00 / set