TSH-35 Laboratory/mini Twin Screw Extruder Machine Price for sale

-

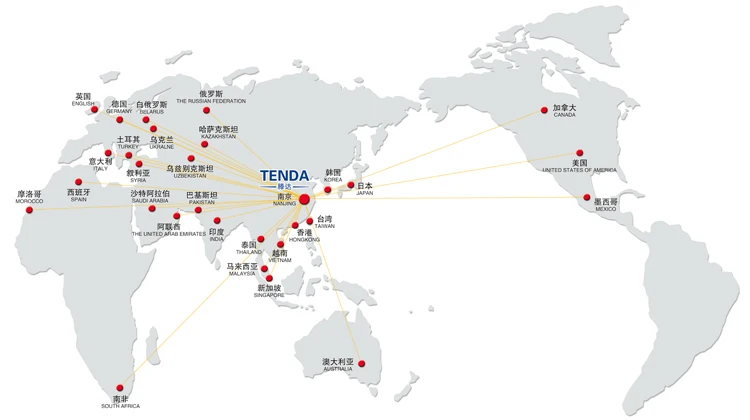

Supplier: Nanjing Tengda Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Nina Chou -

Price: $20500.00 /set -

Min. Order: 1 set

| Port: | Shanghai port; | Brand Name: | TENDA; |

| Application: | Granules; | Payment Terms: | L/C,D/P,T/T,Western Union,MoneyGram,Paypal; |

| Packaging Detail: | Wooden case or 1*20GP container per set; | Application: | Polymer granules; |

| Automatic Grade: | Automatic; | Dimension(L*W*H): | 3500*900*1500mm; |

| Barrel: | Bimetallic alloy bush; | L/D: | 32-68; |

| Warranty: | 1 Year; | Central distance: | 30mm; |

| Certification: | CE & ISO; | Item name: | Twin Screw Extruder Machine; |

| Place of Origin: | Jiangsu China; | Condition: | New; |

| Color: | Any color as you require; | Weight: | 1000kg; |

| Speed: | 400/500/600rpm; | Screw material: | W6Mo5Cr4V2 or 38CrMoAlA; |

| Screw Design: | Double-screw; | Output: | 20-60kg/h; |

| Screw diameter: | 35.6mm; | Plastic Processed: | PP/PE/PET/ABS/PC+additives; |

| Voltage: | 380v 50Hz (customized); | Power(W): | 15kw; |

| Supply Ability: | 25 Set/Sets per Month Twin Screw Extruder Machine Price for sale; | After-sales Service Provided: | Video technical support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Online support; |

TSH-35 Laboratory Twin Screw Extruder Machine Price for sale

Official Youtube Website: https://www.youtube.com/channel/UCM7Vp_mbWDKm3pgK3uyKBbg/featured

Application

1. Using the granulation process, for testing the basic performance of material, such as color, plasticity.

2. Using for developing the new allotment.

Technical Data

| Type | Dia.(mm) | L/D | Speed(rpm) | Motor(kw) | Torque(N.M) | Output(kg/hr) |

| TSH-20 | 22 | 32-60 | 400 | 3 | 4.8 | 2-10 |

| 600 | 4 | 4.8 | 2-15 | |||

| TSH-30 | 30 | 32-56 | 400 | 7.5 | 4.8 | 5-30 |

| 500 | 11 | 4.8 | 5-40 | |||

| 600 | 15 | 6.6 | 15-55 | |||

| TSH-35 | 35.6 | 32-68 | 400 | 11 | 4.6 | 20-60 |

| 500 | 15 | 4.2 | 30-70 | |||

| 600 | 22 | 6.1 | 40-95 | |||

| TSH-40 | 41 | 32-68 | 400 | 22 | 6.0 | 40-110 |

| 500 | 30 | 5.5 | 70-150 | |||

| 600 | 37 | 6.8 | 90-170 |

Advantage

1. Saving material: screw diameter is 35.6mm.

2. Saving space: adopting integrated model, covering 2.0m2.

3. Operated by one person.

4. Convinence mobility design.

Scope of application

1. Special teaching in High Vocational Colleges.

2. New Materials and material modified by macromolecule polymer in High Educational Colleges.

3. Color masterbatch and functional masterbatch production enterprise, testing its despercion and plasticity.

4. Plastic additives enterprise, testing the function of plastic assitives.

5. Sales color masterbatch and plastic additive, providing proofing.

Scope of supply

| No. | Name | Quantity | Specification |

| 1.0 | Feeding system | ||

| 1.1 | Twin-screw feeder | 1 set | |

| 2.0 | Twin Screw Extruder | TSH-35B/600-4.0-40 | |

| 2.1 | Main motor | 1 set | |

| 2.2 | Soft water circulating cooling system (internal) | 1 set | |

| 2.3 | Forced pump vaccum system (internal) | 1 set | |

| 3.0 | Strand Pelletizing System | ||

| 3.1 | Die-head | 1 set | |

| 3.2 | Stainless steel water sink | 1 set | |

| 3.3 | Blow dryer | 1 set | |

| 3.4 | Pelletizer | 1 set | |

| 4.0 | Electrical Control System | ||

| 5.0 | Accompanying spare parts | ||

| 6.0 | Accompanying documents |

Related Spare part

Applications:

Fiber reinforcement: glass fiber, carbon fiber reinforced PP. PA, PBT. ABS. AS, PC, POM, PPS, PET. etc.

Polymer Blending: blending of PC/ABS, PA/ABS,PE/ABS, PP/EPDM, PA/EPDM, PP/ABS,etc .

Incorporation of Fillers: CaCo3, Talc, TiO2, carbon black filled PE, PP, or EVA etc.

Cable Compounds: cable sheath, cable insulation compounds of LDPE, HDPE, LLDPE, MDPE: radiation-crosslinkable compounds; optical fiber protection compounds, heat-shrinkable polymer compounds.

Special Compounds: PPR pipe compounds, PE compounds for crosslinked pipes, tobacco fillter compounds etc.

High Concentration Color Masterbatches: PE, ABS, PS, EVA, PET, PP etc.with high concentration of pigments and other processing aids.

Masterbatches with Flame-Retardants: PP, PA , ABS, EVA, PBT, etc. with flame retardants and other addivives.

Special Functional Masterbatches: Masterbatches with anti-static. anti-bacteria. or other special functional fillers.

Masterbatches for Degradable Polymers: PP, EP, PS, etc. blended with high concentration of starch and other prodbssing aids.

About materials:

Nanjing Tengda Machinery Co.,Ltd.—— To push the research and development of the high-end twin screw extruder machine, our company establised Twin Screw Technology Research and Development Business Division with the No.58 Research Institute of China North Industries Group Corporation Limited in 2013. In order to speed up the industrialization of military-civilian integration technology, the sophisticated technology is injected into out company so as to maximize the advantages of high-end twin screw extruder in China.

Presales service:

>Introducing in detail features and application of the products to customer.

>Selecting economical and practical machine & equipment for customer.

>Providing operation data of the related machine & equipment.

>Providing means of trial performance for customer.

Sales service:

>Recommending engineering conditions required for installation of the machine & equipment.

>Communicating in time the manufacturing progress of the machine with user.

>Providing assistance in technical conditions, screw combination and barrel disposition needed for product.

After-sales service:

>Providing on-the-spot technical assistance in installation, commission and training.

>Filling in detail customer’s information.

>Providing long-term maintenance service and spare parts.

>Giving technical support to customer for developing new product.

>Providing free maintenance for a year.

Q: Are you trading company or manufacturer?

A: We are factory.We have the technical production team,and the workers are all very experienced.

Q: Why choose you?

A:1)You can get a very fair price from us and our price can make you beat your competitors in the market.

2) Our Excellent Service

For a quick, no hassle quote just send email to us

We promise to reply with a price within 24 hours - sometimes even within the hour.

If you need an advice, just call our export office at +86 025 52296133, we will answer your questions immediately.

3) Our quick manufacturing time

For Normal orders, we will promise to produce within 30 working days.

As a manufacturer, we can ensure the delivery time according to the formal contract.

Q: What kind of certification do you have?

A: Our products have obtained ISO9001 and CE certification,the quality can be guaranteed.We focus on the field of extrusion machine,and aim to be the best manufacturer of this field.

Q:What's the payment?

A:L/C, T/T, Western Union, Paypal, Money Gram.

-

mini plastic extruder laboratory micro single screw extruder extrusora

-

20~110mm PE pipe production line plastic pipe making machine

-

Custom Elastic Band Making Machine

-

High precision 0.02mm finishing winding 3D filament making machine hot sale in 2020

-

Certified line extruder SJ30/25

-

EPE foam sheet machine/PE foam network pipe extrusion line,Ellie Whats 008613780912769

-

HDPE plastic pipe making machine/plastic water pipe production line/plastic energy pipe making machine

-

PET Plastic Belt Production LinePET Packing Belt Equipment Belt Making Machine

-

Wood Plastic WPC Door Frame Forming Machine Production Line

-

150mm screw pp pe waste plastic recycling extrusion granulation pelletizing machine production line