Environmental friendly used engine oil recycling machine / waste oil to base oil distillation plant

-

Supplier: Kinetic (Hubei) Energy Equipment Engineering Co., Ltd. -

Region: Hubei, China -

Contact: Ms Amy Luo -

Price: $58000.00 /set -

Min. Order: 1 set

| Heating method: | Molten salt boiler; | Working Pressure: | 20-30KPA; |

| Power(W): | depend on the fact; | Brand Name: | Kinetic; |

| Raw material: | SS and CS; | After-sales Service Provided: | Field installation, commissioning and training; |

| Base oil type: | SN100 SN150 SN250; | Certification: | CE ISO; |

| Application: | Waste Oil Refinery Equipment; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,crude oil refinary price; |

| Separtation methods: | Vacuum distillation; | Voltage: | Customer's Requirement; |

| Warranty: | 2 Years; | Place of Origin: | Henan China; |

| Packaging Detail: | Nude packed or packed in wooden boxes. Environmental friendly used engine oil recycling machine / waste oil to base oil distillation plant; | Condition: | New; |

| Supply Ability: | 5 Set/Sets per Year waste lube oil to base oil refining plant; | Dimension(L*W*H): | depend on the fact; |

| Weight: | depend on the fact; | diesel flash point: | ≥220℃; |

| Flow: | 1-20t/h; | Port: | Shanghai,Qingdao,wuhan; |

| Capactiy: | 20-500TPD; | continous time: | 8000h; |

| Product name: | waste engine oil recycling to base oil plant; | Applicable Industries: | Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory,Farms,Home Use,Retail,Construction works ,Energy & Mining,Food & Beverage Shops; |

Environmental friendly used engine oil recycling machine / waste oil to base oil distillation plant

1.Waste engine oil waste car motor oil refinery to base oil ?

The main technology of waste oil regeneration in abroad is Kleen,Meinken,IFP,KTI,Snamprogetti,DOH,DCH,BERC and Recyclon.etc.New processes that have been applied abroad include ultrafiltration, centrifugal separation, molecular distillation, flocculation, solvent refining, etc.In the late 1980s, two regeneration processes were developed in China.One is distillation-extraction-clay process, which uses ethanol as solvent for extraction; the other is high temperature clay process, which combines distillation and clay treatment in the same process.Recent thin film evaporator - furfural refining-clay process can extract more base oil fractions than conventional vacuum distillation, furfural has better extraction effect than ethanol, and the yield of base oil is higher.

According to the deterioration mechanism and degree of lubricating oil, the regeneration technology of waste engine oil can be divided into re-purification process, fine refining process and re-refining process.

2.Technology of our company

1) Process flow description

The process of waste oil reduction and regeneration base oil is introduced as follows: Our company specializes in the production of waste oil regeneration equipment and process research and development for more than ten years, and constantly explores and improves the technology. Combining with the advantages and disadvantages of the current equipment process, we focus on the materials in the process of waste oil processing equipment, which are easy to coke at high temperature, have high operating cost and have many potential safety hazards. The problem of high overhaul rate and high technical difficulty has been discussed and studied, and a lot of manpower and material resources have been invested. Through repeated testing and continuous improvement, the problem of easy coking of materials at high temperature has been successfully solved.

2) Production process flowchart

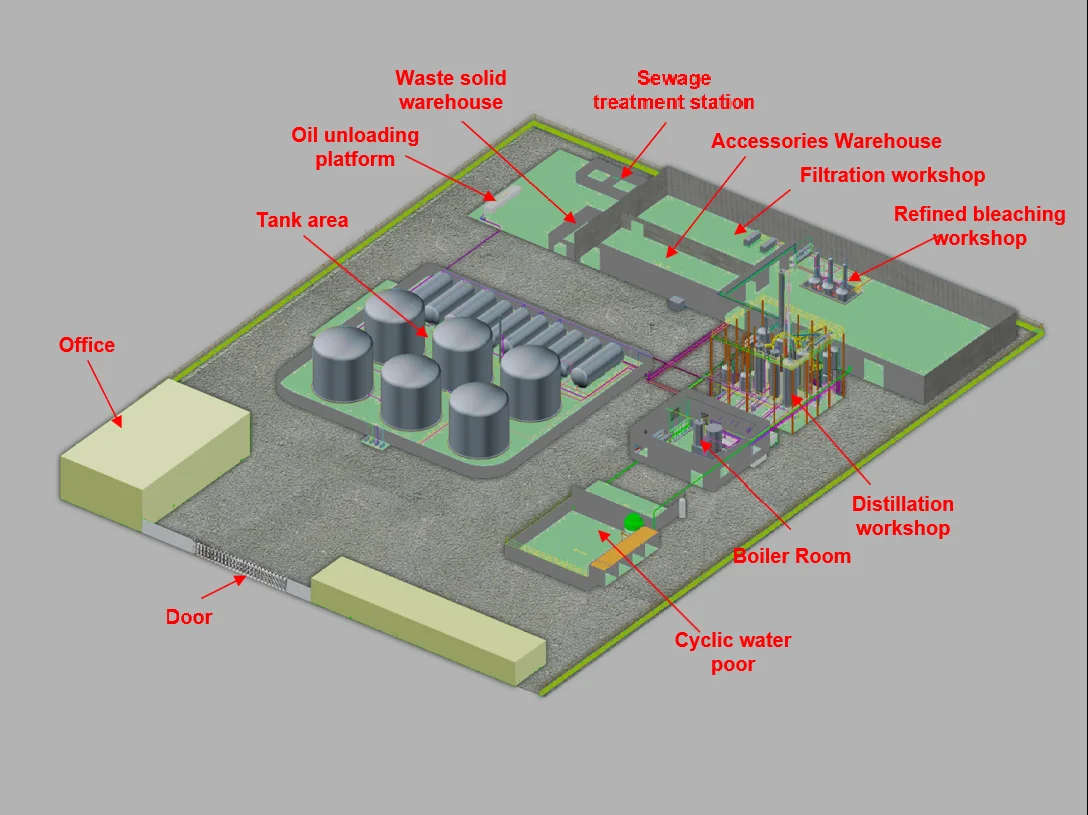

3)Project overview(Examples for reference)

1)Project Name: 18,000T/a waste lubricant recycling project;

2) Nature of the industry: waste resources and recycling of waste materials;

3) Total investment: 20 million yuan

4) Land area: 14,000 square meters, construction area 5,120 square meters;

5) Greening area: The whole plant has a green area of 1820 square meters, and the greening rate is 13%;

6) Number of employees: 30 staff members;

7) Hours of work: 300 days for the whole year, 24 hours for the day, and 7,200 hours for the whole year;

3.Application

4.Advantages:

1.Low investment, low wastage and high yield.89-96% high recovery rate

2.Can be used as the base oil of international standards, SN150.SN250.SN350

3.Easy to operate

5.Main Equipment introduction

1)Distillation tower introduction

Fractionating tower with structured packing

The tower is divided into:

a.In the top of the tower, the product is the first-line oil.;

b.Second-line return and recovery section, the product is second-line oil;

c.Third-line return and recovery section, the product is third-line oil;

2)Tank and warehouse storage

6.The quality of oil from our customer:

7.Main product testing index

| (Third-line oil) finished product quality inspection standard HVI250 | |||

| 1 | Test items | Indicators | Reference standard |

| 2 | Flash point | ≥220℃ | GB/T3536-1983 Flash point and flash point determination of petroleum products (Cleveland open cup method) |

| 3 | Pour point | ≤-12℃ | GB/T3535-1983 Petroleum products pour point measurement method |

| 4 | Chroma | 2 | GB/T6540-1986 Oil product color measurement method |

| 5 | Kinematic viscosity (40 degrees) | 42-55mm²/s | GB/T265-1988 Kinematic viscosity measurement and dynamic viscosity measurement of petroleum products |

| 6 | Kinematic viscosity (100 degrees) | Report | GB/T265-1988 Kinematic viscosity measurement and dynamic viscosity measurement of petroleum products |

| 7 | Viscosity index | ≥100 | GB/T1995-1998 Oil Products Viscosity Index Calculation Method |

| 8 | Acid value | ≤0.03(mgkoh/g) | GB/T264-1983 Oil product acid value measurement method |

| 9 | Demulsification (54 degrees) | ≤10min | GB/T7305-2003 Separation of oil and synthetic liquids |

| 10 | Water content | Trace | GB/T260-1997 Oil Products Water Content Measurement Method |

8.Packing and Delivering

Used Motor Oil/Pyrolysis Oil Recycling Plant to Base oil .

Packing Details : Wooden case package of standard export.

Delivery Details : 15-30 days after received the deposit.

We will provide the most reliable, safest mode of transportation, in order to save shipping cost.

9.Successfull Installation

Kinetic (Hubei) Energy Equipment Engineering Co., Ltd. is a professional and modern grain and oil machinery engineering equipment manufacturer integrating research, manufacturing and installation. We have obtained rich experience and practice in palm fruit oil machine, vegetable oil pretreatment, prepress,extraction, sophisticated technology and equipment designs etc. owing wide international market in more than 130 countries and regions.

We are proud to guarantee that, with our strong technical background and communication capability, our sales/support engineers are able to answer your most complicated technical questions over the phone in English. That would save a lot of time for communication.

10. FAQ

-

Yangjiang waste oil refining equipment recycling waste motorcycle or automobile oil waste oil regeneration machine

-

Recycling waste oil into diesel oil refinery is highly profitable and low cost

-

China Made Heavy Fuel Oil Distillation Mini Refinery

-

Standard Diesel and Gasoline or Crude Distillation Units in U.S. Crude Oil Refinery

-

2023 NEW Oil filter machine Oil filter equipment manufacturing

-

New continuous oil filter oil recovery machine

-

Factory supply portable oil purifier hydraulic oil filter cart oil purifier unit

-

500kg/day small edible oil refiner crude oil refiner HJ-JLYJ200

-

Distillation Unit Price of Small Crude Oil Refinery

-

New energy TYR waste oil to diesel plant edible oil recovery machine oil filter machine

Other Products

-

$650.00 / cubic meter

$650.00 / cubic meter