China Made Heavy Fuel Oil Distillation Mini Refinery

-

Supplier: Henan Barui Environmental Protection Equipment Co., Ltd. -

Region: Henan, China -

Contact: Mr Andy Lee -

Price: $50000.00 /set -

Min. Order: 1 set

| heating method: | indirect | raw material: | Crude Oil & Waste Engine Oil & Waste Oil |

| Warranty: | 1 year, 1 year | flow: | 50L/min-300L/min |

| Health status: | new | Core component warranty: | 1 year |

| capacity: | 5-100 tons/day | weight: | 30 kg |

| Dimensions (L*W*H): | 40HQ container | Showroom location: | Russia |

| Finished product: | Petrol and diesel | application: | Waste oil refining equipment |

| Package preview: | Applicable industries: | Manufacturing plants, energy and mining | |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Supply capacity: | Annual output of 100 sets of small oil refineries |

| Packaging Details: | All goods are packed in export standard to ensure no damage during transportation. | Origin: | Henan, China |

| type: | Continuous oil distillation machine | Marketing Type: | New design for 2023 |

| advantage: | Energy saving and environmental protection | Mechanical test report: | if |

| Core components: | Pressure Vessels, Reactors, Condensers, Heat Exchangers | Voltage: | 380V/50Hz |

| port: | Lianyungang | strength: | 12-24KW |

| Material: | Q235R/Q345R Boiler Steel & S.S.304/316L | brand: | barui |

| Name: | Small refinery for distillation of heavy fuel oil | Video outbound inspection: | if |

Henan Barui China Manufacturing Heavy Fuel Oil Distillation Small Refinery

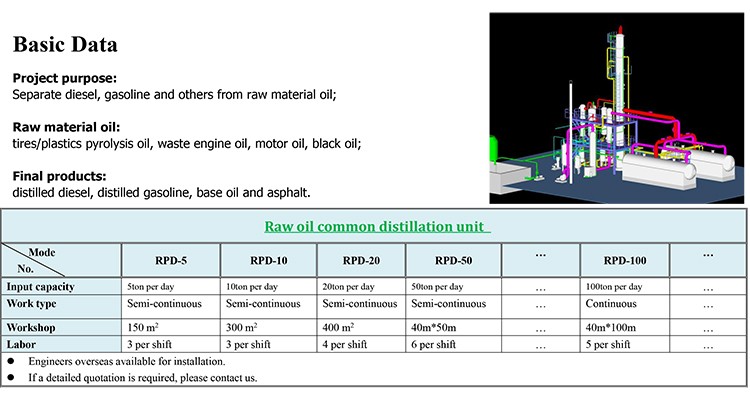

Henan Barui small oil refinery is a new product developed by our company combining dozens of latest technologies. Its technological process is that the cold crude oil is heated through the top of the distillation tower, and then dehydrated in the dehydration tower. It is then heated in a furnace. When the crude oil is heated to the desired temperature, it will enter the distillation column.The distillation device is a self-split atmospheric distillation device, which uses a semi-continuous distillation process to refine waste oil under negative pressure.This design enables rapid extraction of light and heavy fractions from different fractions with given different temperature controls.

The device has the following advantages:

(1)energy saving;

(2)save costs;

(3)Easy to operate and low operating cost, only need 1-2 workers to control the machine;

(4)Environmental friendly;

(5)High recovery rate;

(6) Efficient vacuum system;

(7) Efficient safety devices;

(8)high quality refined oil, without any oxidative discoloration, without any peculiar smell.

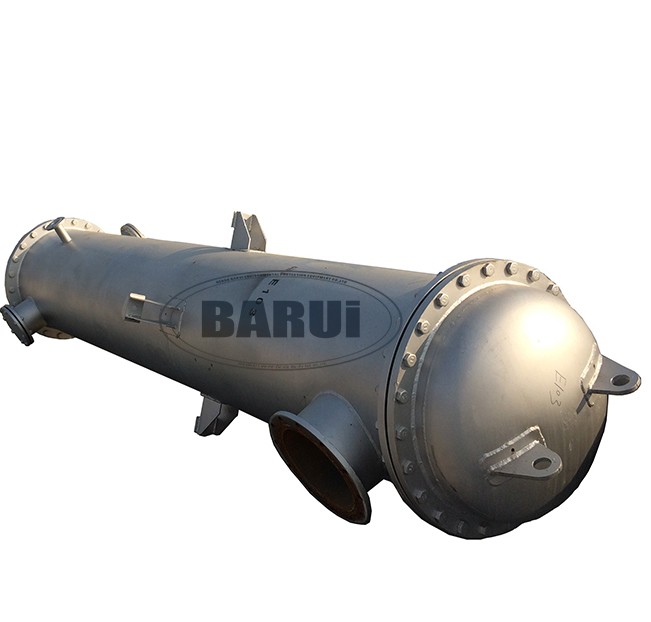

heat exchanger

In the heat exchanger, flue gas and crude oil are used as media to save energy.

heating furnace

Compared with the tube heating furnace, the furnace can reach a higher process temperature, which can reach more than 600 degrees Celsius.

Dust tower

1. Save energy;

2. Low production cost.

Distillation tower

The distillation column adopts high-efficiency packing and suitable column internals, and has strong impurity removal and dehydration capabilities.

High temperature gas-liquid separator

The water content after separation is less than 1%, which can meet the requirements of industrial production.

tank

The vertical design facilitates the conduction of non-condensable gases.

residue tank

The tank body is a horizontal tank body, and the sight glass and tank body are resistant to high temperature.

condenser

The vertical condenser prevents oil accumulation, thus guaranteeing cooling efficiency.

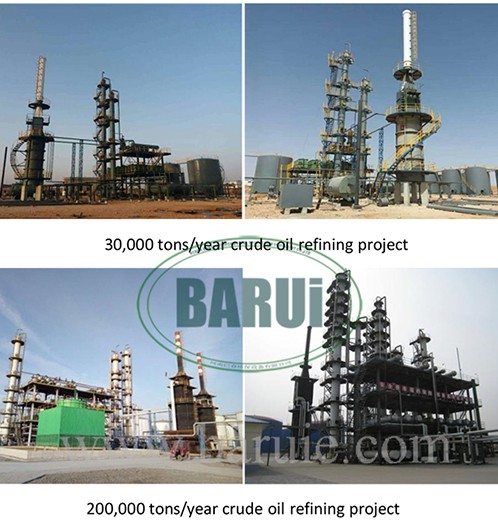

Henan Barui Environmental Protection Equipment Co., Ltd.

Integrity is the first principle of our international trade. Barry pays more attention to technological progress, environmental protection, production safety and professional services, and looks forward to further cooperation with you!

We are a team with professional knowledge and absolute responsibility attitude.

Professional designer team

Based on professional knowledge and theory, professional team designers continue to create more new high-quality products with a serious and responsible attitude.

quality product

High-quality product display

The display of high-quality products can help customers quickly find the products they need and obtain product information.

24-hour service

We are online 24 hours to answer questions about products. Please contact me if you have any questions!

Customers come to visit our factory

Simulation operation demonstration

Explain in detail to customers and negotiate with customers

Welcome to contact me, 24 hours service!

-

Yangjiang waste oil refining equipment recycling waste motorcycle or automobile oil waste oil regeneration machine

-

Recycling waste oil into diesel oil refinery is highly profitable and low cost

-

Standard Diesel and Gasoline or Crude Distillation Units in U.S. Crude Oil Refinery

-

2023 NEW Oil filter machine Oil filter equipment manufacturing

-

New continuous oil filter oil recovery machine

-

Factory supply portable oil purifier hydraulic oil filter cart oil purifier unit

-

500kg/day small edible oil refiner crude oil refiner HJ-JLYJ200

-

Distillation Unit Price of Small Crude Oil Refinery

-

New energy TYR waste oil to diesel plant edible oil recovery machine oil filter machine

-

Small refinery to make clean diesel from waste oil

Other Products

-

$12000.00 / set

$12000.00 / set -

$10000.00 / set

$10000.00 / set -

$300000.00 / set

$300000.00 / set -

$12000.00 / set

$12000.00 / set -

$15000.00 / set

$15000.00 / set -

$13000.00 / set

$13000.00 / set -

$28000.00 / set

$28000.00 / set