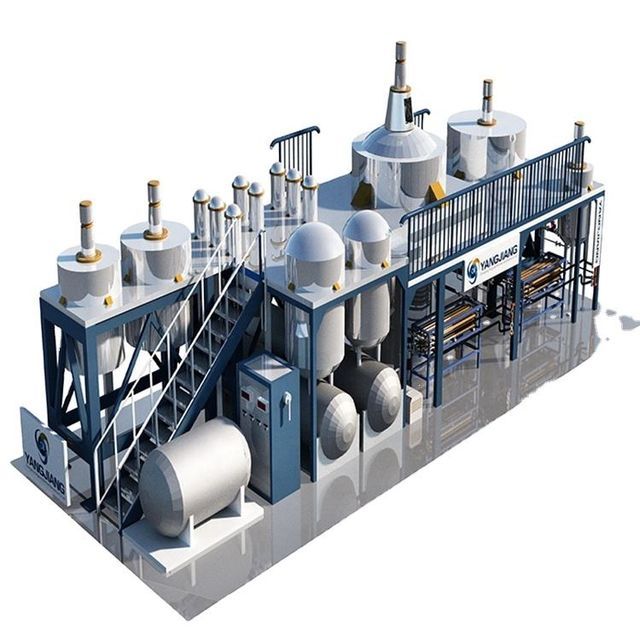

Yangjiang waste oil refining equipment recycling waste motorcycle or automobile oil waste oil regeneration machine

-

Supplier: Chongqing Yangjiang Machine Manufacture Co., Ltd. -

Region: Chongqing, China -

Contact: Ms Kayla Tang -

Price: $130000.00 /set -

Min. Order: 1 set

Product details

| Warranty: | 1 year | brand: | Yangjiang |

| Dimensions (length*width*height): | Refer to actual data | Package preview: | |

| Applicable industries: | Manufacturing plant, other | Supply capacity: | 5 sets per year |

| payment terms: | L/C, Western Union, T/T, MoneyGram | Voltage: | 380 volts |

| Video outbound inspection: | if | port: | Chongqing, China |

| Core component warranty: | 1 year | Showroom location: | not any |

| Core components: | Engines, motors, pressure vessels, pumps | Marketing type: | Hot Products |

| flow: | 70 tons/day | strength: | About 100 kilowatts |

| Place of origin: | Chongqing, China | Mechanical test report: | not available |

| Packaging details: | The waste black engine oil diesel distillation machine is packed in bare containers, and the spare parts are packed in sturdy wooden boxes. It is suitable for long-distance shipping or freight and changeable climates, and has good moisture-proof and shock-proof properties. | weight: | 50kg |

| Health status: | new |

Waste oil enters base oil distillation machine

product description

Technical Description

YJ-TY series waste oil to base oil distillation machine can recycle various waste oils, including black engine oil, mineral oil, synthetic oil, industrial lubricating oil, hydraulic oil, transmission oil, gear oil or mixed oil, to purify yellow base oil , such as SN150, SN200, SN300 and SN500. We use vacuum distillation to remove contaminants from waste oil, reduce pollution and recycle waste oil for reuse. Vacuum distillation is a method of distillation that reduces the pressure above the liquid mixture to be distilled below its vapor pressure (usually below atmospheric pressure), causing the most volatile liquids (those with the lowest boiling points) to evaporate.

The entire process is physical distillation, and the clean oil is free of acids and chemicals. And the machine will distill out the components in the waste oil without changing the quality and composition of the oil.

Depending on the raw material quality, the base oil recovery rate is 82-90%.Color index 1-1.5.

Flow chart and work process

Processing:

1. First, pump the pretreated waste oil into the chemical reaction kettle and add the chemical solution. Continue to stir the oil in the reactor. After stirring in the reaction kettle, the oil is allowed to stand to separate the impurities and part of the colloid at the bottom of the reaction kettle. Oil treated with this chemical catalyst will not crack even if it is heated to 400 degrees in the atmosphere. (In the atmosphere, untreated oil begins to crack at 300°C, significantly reducing the quality and recovery rate of regenerated oil). 2. After chemical treatment, the waste oil is heated by an electric heater to control the oil temperature within 330 degrees. When the waste oil temperature rises to about 55°C, the first batch of gasoline begins to be released from the waste oil. When the oil temperature rises to around 110°C - 220°C, the second diesel is released. Base oil is the main product and the distillation temperature is around 220°C and continues up to 330°C. Light base oil is distilled at around 220℃-300℃, and heavy base oil is distilled at around 300℃-330℃. Finally, the process ends when the residual material in the waste oil has not evaporated. At this point, the heating during distillation stops and the process is essentially complete. We can pump out the residual oil and use it as asphalt and heavy fuel oil. 3. Yangjiang’s machine is equipped with a heating system, and you can choose a hot gas heating system, an electromagnetic heating system or a tubular heating system.

The fuel is diesel, and when 1,000 liters of waste oil is recycled, the fuel consumption is about 15-20 liters of diesel.

Product parameters

thing | standard test | data | ||

Light base oil | Heavy base oil | |||

Viscosity(40℃) | mm2/sec | 16~32 years old | 28~72 | |

Viscosity index | not applicable | ≥99 | >110 | |

appearance | not applicable | transparency | transparency | |

color index | ASTM D1500 No. | ≤1 | ≤2 | |

pour point | ℃ | -15℃ | -10℃ | |

Moisture content | % (weight/weight) | ≤0.05 | ≤0.05 | |

Flash point (open circuit) | ℃ | ≥180 | ≥210 | |

Ash content | % (weight/weight) | 0.005 | 0.005 | |

Carbon residue | % (weight/weight) | ≤0.13 | ≤0.13 | |

Corrosion (copper/100℃/3H) | not applicable | qualified | qualified | |

acidity | Magnesium hydroxide/g | ≤0.05 | ≤0.05 | |

VIEW MORE

You may like

-

Recycling waste oil into diesel oil refinery is highly profitable and low cost

-

China Made Heavy Fuel Oil Distillation Mini Refinery

-

Standard Diesel and Gasoline or Crude Distillation Units in U.S. Crude Oil Refinery

-

2023 NEW Oil filter machine Oil filter equipment manufacturing

-

New continuous oil filter oil recovery machine

-

Factory supply portable oil purifier hydraulic oil filter cart oil purifier unit

-

500kg/day small edible oil refiner crude oil refiner HJ-JLYJ200

-

Distillation Unit Price of Small Crude Oil Refinery

-

New energy TYR waste oil to diesel plant edible oil recovery machine oil filter machine

-

Small refinery to make clean diesel from waste oil

Other Products

-

$32000.00 / set

$32000.00 / set -

$20000.00 / set

$20000.00 / set -

$4700.00 / set

$4700.00 / set -

$12000.00 / set

$12000.00 / set

Related Search

chongqing junneng waste oil filter machine

beef tallow oil refining equipment

cotton waste charcoal making machine suppliers

wasted wood briquette machine

waste tire grinding machine

waste rubber production machine

waste plastic refinery machine

waste tyre cutter machine

oil press machine

oil spray machine