Power Saving Used Oil to Diesel Oil Oil Refinery Machine Plant

-

Supplier: Chongqing Yangjiang Machine Manufacture Co., Ltd. -

Region: Chongqing, China -

Contact: Ms Kayla Tang -

Price: $20000.00 /set -

Min. Order: 1 set

| Weight: | 78T; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Technology: | Oil distillation; | Final product: | Diesel fuel; |

| Recycling rate: | 93%-95%; | Raw material: | Used oil; |

| Power(W): | 210KW; | Density (15℃): | 0.84kg/L; |

| Place of Origin: | Chongqing China; | After-sales Service Provided: | Field installation, commissioning and training; |

| Warranty: | 1 year; | Supply Ability: | 10 Set/Sets per Month; |

| Voltage: | Customer's Requirement; | Flash Point (closed cup): | 60℃; |

| Sulfer content: | 0.151; | Brand Name: | YANGJIANG; |

| Payment Terms: | L/C,T/T,Western Union,MoneyGram; | Packaging Detail: | To be packed in strong wooden cases, suitable for long distance ocean or freight transportation as well as changing climate and with good resistance to moisture and shocks.; |

| Dimension(L*W*H): | 80*20*8M; | Condition: | New; |

| Applicable Industries: | Manufacturing Plant; | Flow: | 80T/Day; |

| Certification: | CE ISO SGS; | Port: | any port of China; |

| Function: | Recycle; |

Power Saving Used Oil to Diesel Oil Oil Refinery Machine Plant

YJ-DSL series is suitable for used engine oil, motor oil, heavy fuel, bunker oil, oil sludge, kinds of lubricant oil and other oil to clean diesel. After our machine's recycling, then the waste oil can be changed into clean diesel oil. Which can be used in ships, trucks, generators and so on directly

Working Process

The working process for Scrap Engine Oil To Standard Clean Diesel Oil Distillation Refinery Machine is to pump the waste oil into the distillation kettle, the heating system will start the stirring device. Gasoline components and water in the used oil can be distilled out when the temperature reaches to 50 ℃-100℃. When the temperature reaches to 160 ℃-260℃, after efficient catalytic and cracking, the light and heavy components will convert to diesel from vapor. Finally, we filter all collected diesel oil liquid, then we can get high quality finished diesel oil.

Cracking Process

The method for Scrap Engine Oil To Standard Clean Diesel Oil Distillation Refinery Machine is cracking it into fuel. The feature for the cracking process is very safe cause the temperature setting is rigorous and the machines is stabilization. Our engineers commit to design the most reasonable and high efficient distillation system to realize the profit maximization of the both parties.

Features

1)High recovery rate

the highest recovery rate can reach 93-95%. Gasoline 2-5%, diesel fuel 85-90%.

2)Easy operation

The YJ-DSL series machine is easy to operate, low running cost, it need only 1-2 workers to operate

3)Rich raw material

YJ-DSL series can recycle all kinds of used black diesel, used engine oil, used machine oil, used mineral oil and almost all industrial oil to diesel fuel. The cracked oil is able to be used as industrial or civil-use fuel, even power driven fuel.

4)Efficient catalyst

It is normal safe and available. It can help the waste oil further catalytic cracking to ensure a higher recovery rate and good quality of oil

Application

| Machine Parameter | ||||||||||

| Handling capacity | T/D | 0.5 | 2 | 4 | 5 | 10 | 20 | 30 | 50 | 100 |

| Recovery rate | % | <=93 | ||||||||

| Teperature | ≤ 430 | |||||||||

| Working Noise | dB (A) | 45 | 60 | 65 | 65 | 65 | 70 | 70 | 75 | 75 |

| Total power | KW | 10 | 15 | 20 | 22 | 55 | 90 | 130 | 170 | 260 |

| DimensionMM | L | 5000 | 8000 | 1100 | 12000 | 14000 | 25000 | 30000 | 60000 | 100000 |

| W | 3500 | 4000 | 4500 | 5000 | 8000 | 8000 | 10000 | 16000 | 22000 | |

| H | 6000 | 7000 | 7000 | 7000 | 7000 | 8000 | 8000 | 8000 | 8000 | |

| Diesel Oil Parameter | ||||

| Item | Test standard | Result | Standard value | |

| Density(15℃) | ASTM D1298 | 0.84 kg/l | ---- kg/l | |

| Kinematic viscosity(40℃) | ASTM D445 | 3.36 cst | 1.6-5.8 cst | |

| Flash point(closed cup) | ASTM D93 | 60 ℃ | ≥55 ℃ | |

| Pour point | ASTM D97 | -19 ℃ | ≤ 0 ℃ | |

| Distillation temperature | 10% oint | ASTM D86 | 204 ℃ | --- |

| 50%point | 289 ℃ | ≤300 ℃ | ||

| 90%point | 344 ℃ | ≤355 ℃ | ||

| 95% point | 359 ℃ | ≤365 ℃ | ||

| Cetane index | ASTM D976 | 54.42 | ≥45 | |

| Water content | ASTM D95 | Trace%vol | ≤Trace %vol | |

| Sulfur content | ASTM D1226 | 0.151%wt | ≤0.2 %wt | |

1.what ability we have?

mature technologies and skillful workmanship (we control every single manufacturing process and make sure it will be done perfectly in our factory with the lowest cost with the best quality assurance). products quality guarantee and about 30 days free train(competitors cant spend much time in you factory,stay long you will find many problems about their machine)

2.Why we need to add the catalyst?

Catalyst will keep the recycled oil stabilization, avoiding the recycled oil oxidate and color change back to black. So the recycled oil from our machine will keep yellow at least half one year or one year.

3.Why the machine need work under vacuum condition?

The machine work under negative pressure, the boiling rage of the used oil is lower under high vacuum condition, if without vacuum unit, the oil will crack when temperature up to 420-450 degree( and the oil will become to diesel when temperature is 450 degree)

-

Yangjiang waste oil refining equipment recycling waste motorcycle or automobile oil waste oil regeneration machine

-

Recycling waste oil into diesel oil refinery is highly profitable and low cost

-

China Made Heavy Fuel Oil Distillation Mini Refinery

-

Standard Diesel and Gasoline or Crude Distillation Units in U.S. Crude Oil Refinery

-

2023 NEW Oil filter machine Oil filter equipment manufacturing

-

New continuous oil filter oil recovery machine

-

Factory supply portable oil purifier hydraulic oil filter cart oil purifier unit

-

500kg/day small edible oil refiner crude oil refiner HJ-JLYJ200

-

Distillation Unit Price of Small Crude Oil Refinery

-

New energy TYR waste oil to diesel plant edible oil recovery machine oil filter machine

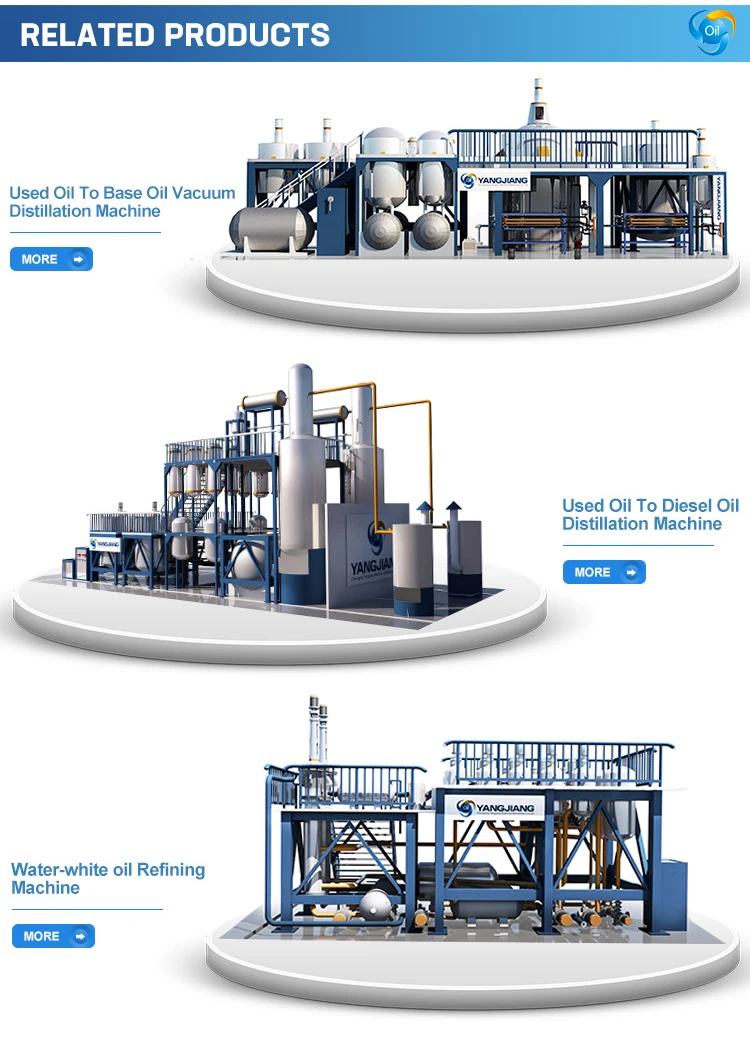

Other Products

-

$130000.00 / set

$130000.00 / set -

$32000.00 / set

$32000.00 / set -

$4700.00 / set

$4700.00 / set -

$12000.00 / set

$12000.00 / set