Automatic Sardines saury canned food machine

-

Supplier: Shanghai Leadworld Machinery Technology Co., Ltd. -

Region: Shanghai, China -

Contact: Ms LORA LI -

Price: $10000.00 /set -

Min. Order: 1 set

| Application: | Beverage,Chemical,Food; | Applicable Industries: | Hotels,Manufacturing Plant,Food & Beverage Factory,Retail,Food Shop,Printing Shops,Food & Beverage Shops; |

| Driven Type: | Electric; | Capacity: | 0-300canned/h; |

| Place of Origin: | Shanghai China; | Voltage: | Customer's Demand; |

| Local Service Location: | None; | Function: | produce meat canned; |

| Payment Terms: | L/C,T/T,MoneyGram; | Video outgoing-inspection: | Provided; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Usage: | to produce any kinds of canned food; |

| Weight: | 800kg; | Supply Ability: | 100 Set/Sets per Month; |

| Name: | fruit canned production line; | Marketing Type: | Hot Product 2019; |

| Automatic Grade: | Automatic; | Warranty: | 1year,1 Year; |

| Dimension(L*W*H): | 7450*1000*1800mm; | Packaging Detail: | exported wooden packing as standard; |

| Brand Name: | leadworld; | Machine type: | beef canned production line; |

| Showroom Location: | None; | Type: | Packaging Line; |

| Warranty of core components: | 1 YEAR; | Keywords: | fish canned food machine; |

| After Warranty Service: | Video technical support,Online support,Spare parts; | Certification: | ISO SGS; |

| Machinery Test Report: | Provided; | Key Selling Points: | stable; |

| Other name: | pineapple canned machine; | Product name: | cucumber canned machine; |

| Packaging Type: | Barrel,Bottles,Cans,Case; | Core Components: | Motor; |

| Packaging Material: | Glass,Metal,Plastic; | Condition: | New; |

| Port: | shanghai port; |

Automatic Sardines saury canned food machine

Super septmeber Automatic fish canned food machine

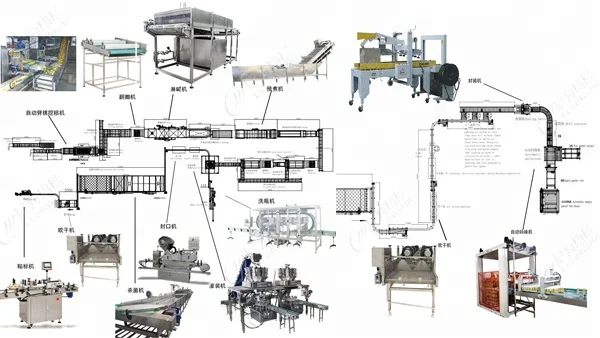

Item | Name | Model specifications |

1 | Washing Machine | Bubble 3T/H |

2 | Soak Machine | Suggest use sinks 2T/PCS And you can buy this in your city |

3 | Precooker | With cooling 5min (85degree-90degree) L=10m W=1100mm |

| Drain off water and cooling | 55degree-60degree L=6m |

4 | Filling Machine | use measuring working way |

5 | Filling Machine | liquid |

6 | Exhaust | Glass Bottle |

7 | Capping Machine | with steam |

8 | Sterilization with cooling and drying | 120degree 1500mm*4250mm with 4pcs cages,4pcs push the car and 30pcs dummy plate |

10 | Labeling Machine |

First clearing and removing impurity------10-12 Hours of immersion-----cooking 5min (85degree-90degree)----drain off water and cooling to 55degree-60degree----

then first filling bean,second filling liquid-----exhaust-----capping-----sterilization---cooling after net can of labeling, finished product storage.

Machine descriptions:

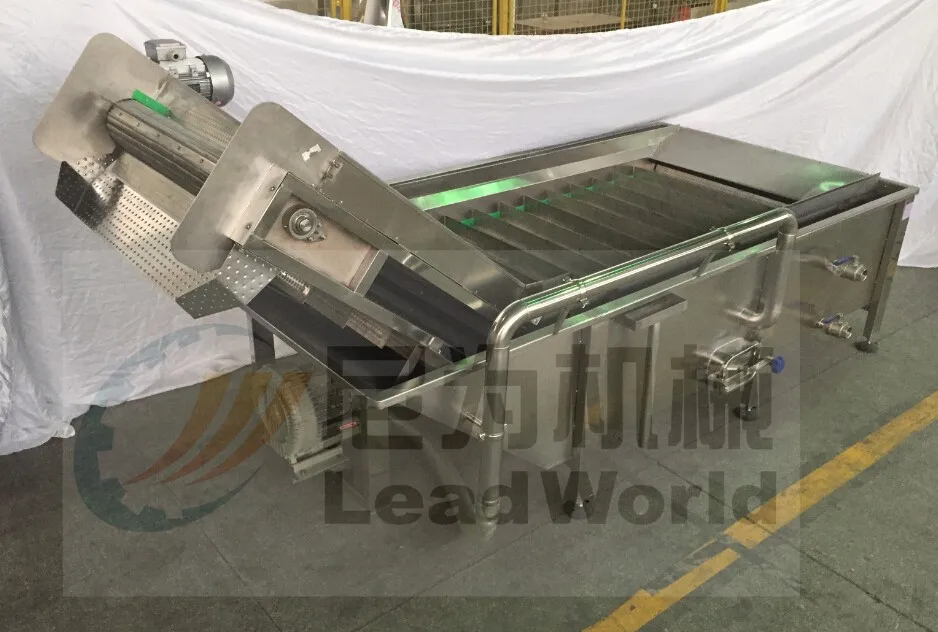

1. washing

Descritions:

1, raw materials under the action of pressure and force bubbles sink was fully broken up, turn the flow, cleaning, transfer. Wash off the sand from the material surface sink to the bottom of the isolation barn, will not happen again flips reflux pollution, according to impurities floating water discharged from the overflow, the water and then cleaned by spraying cleaning materials, to the next one Step

2, the device in addition to motors, bearings and other standard parts are made of stainless steel SUS304 / 2B material, in full compliance with the export of food hygiene requirements. The device is an efficient cleaning ability, energy-saving, water-saving, avoiding the waste of resources to reduce production costs

2.precooker

Features and uses:

The machine uses SUS304 stainless steel chain plate, mesh belt,mesh belt with high intensity,small scale, difficult deformation, easy maintenance,etc., the whole machine balanced running, low noise, greatly improving the work efficiency

This machine is heating mode of electric heating.The machine transmission system adopts gear motor speed regulation which make the conveyor belt speed adjustable.

Drain offwater and cooling

Features and uses

1.The operation is simple, and 1.The speed of the cooling machine can be arbitrary adjustment.

2.Machine as a whole is imported SU5304 stainless steel material and environmental health.

3.Cooling water adopts single split type refrigerator which has a beautiful appearance and automatic control system.

4.The machine mesh belt is chain plate, mesh belt, mesh belt with high intensity, small scale, difficult deformation, easy maintenance, etc, the whole machine balanced running,low noise, greatly improving the work efficiency.

Multifunctional product filling machine

Filling machine of liquid

Overall structure is advanced, simple, reasonable, its transmission and elevating driving on rack stainless steel workbench, good waterproof performance, health and reliable, convenient adjustment and maintenance.Filling machine elevator guide rod in a set inside, with lubrication points, ensure flexible adjustment for the long term.Filling body parts such as STS304 stainless steel refined but become, have guide ring to avoid metal friction, adopt Taiwan han litres of sealing element, sealed performance is good.Filling valve speed, flow rate of 200 ml/s, exhaust is fast, accurate liquid level and rice and liquid filling at the same time.

Automatic glass bottle capping machine

Machine is suitable for dressing, canned, beverage, the most environmental protection glass bottle packaging, and have higher request for vacuum bottle, 4-groove cover glass bottles with screw cap seal, after the match on vacuum system, can to suction vacuum glass bottles first, and then to screw cap, to extend the shelf life of bottles of content and enhance the taste, and no heat to keep the material colour and lustre is constant.

The machine with several groups of German SICK smart sensors, combined with the corresponding pneumatic components, can make glass bottles randomly access screw cap machine into the driving plate, discontinuous production, and need not to care, and to achieve without cover transport into the function of the bottle, so as to implement automatic into the bottle, automatic screw cover, automatic vacuum, the most advanced, safe and reliable products for the same type of screw cap equipment.

Sterilization and cooling

Continuous spray sterilization, cooling, introduction of advanced foreign countries technology, Italy, Taiwan and other similar products on the basis of the new design.Is mainly used for all kinds of bottled and canned drinks, canned fruit and vegetable of atmospheric pressure sterilization, can also be used for PET polyester bottle package of tea drink, fruit juice drinks after hot filling of the cooling and sparkling beverages, beer bottle;

Adopt imported high resistance [polypropylene (CPP) chain plate, with smooth surface, ground resistance loss, and prevent the container at the bottom of the scratch, mesh belt under the food hygienic requirements, and get the American FDA approval;

Labeling machine

Usage:

KL-700 High-speed Fixed-point Round Labeling Machine is suitable for round labeling, especially with the labeling of canned products, machine body is small, can be used in a small place, but also can be wiring to product line.

Characteristic

KL-700 is mainly composed of SUS304 chassis; conveyor belt; Split bottle; Sponge wheel; labeling head; head adjustment etc. Use Siemens PLC, touch screen; servo motor as the main components, control devices run at high speed. Equipment safety, efficiency, and stability; comply with GMP, CE specifications.

Friendly operation interface, Easy setting, Main Function: Product Count, Output Setting, Parameters Memory, Equipment State Monitoring, Device Failure Automatic Shutdown, Alarm Fault Location and Help Information

Final product:

working house:

Our customer:

shipping:

\

\

Our company instruction:

FAQ:

1. What's the material of your machine:

A:mainly is 304SUS or 316SUS.

2. can this machine be suitable for different kind of fruit, meat and vegetable?

A:yes, we can design the machine according to your product.

3. what's the capacity of this line?

A: we can customize the production line range from 0-20000bph, even bigger.

4. are you a factory or trading company?

A: we are factory which located in Shanghai city of China. We have ourselves design team.

-

Metal can end making machine/can end production line

-

High-speed automatic carton cartoon box folding gluing machine corrugated carton carton gluing machine

-

Fully automatic high-speed vertical carton packaging food pizza bottle soap gloves plastic carton box packing machine

-

Carton Liner Bag in Box Line for Packaging Margarine Butter Semi-Liquids

-

Fully-automatic Bag in Box Filling Packaging Line

-

A full set of automatic filling and sealing pure drinking sachet water packaging line

-

Y-Pack buy kn94 n95 facial mask carton packaging machinery automatic cartoning machine cartoning machine

-

Fully automatic single-sided e-groove corrugated cardboard carton carton product making machine

-

Best Selling Automatic Premade Bags Automatic Filling Sealing Packaging Machine

-

50-220L steel drum/barrel making machine

Other Products

-

$48000.00 / set

$48000.00 / set -

$40000.00 / set

$40000.00 / set -

$6000.00 / set

$6000.00 / set -

$3000.00 / set

$3000.00 / set -

$40000.00 / set

$40000.00 / set -

$30000.00 / set

$30000.00 / set -

$2500.00 / set

$2500.00 / set -

$37720.00 / set

$37720.00 / set -

$5000.00 / set

$5000.00 / set -

$5000.00 / set

$5000.00 / set