Fire fighting material mixing machinery production line

-

Supplier: Zhengzhou Yishang Machinery Equipment Co., Ltd. -

Region: Henan, China -

Contact: Mr Henry Han -

Price: $49800.00 /set -

Min. Order: 1 set

| Voltage: | 380V/customize; | Features: | Full Automatic; |

| Packing scope: | 5-50kg; | Port: | Qingdao/Shanghai/Tianjin; |

| ceramic adhesive: | Ceramic tile production line; | Applicable Industries: | Manufacturing Plant; |

| Place of Origin: | Henan China; | Mixer volume: | 2cubic; |

| Brand Name: | Yi Shang; | Worker Required: | 2-3 Person; |

| Package Preview: | ; | Key Selling Points: | High Productivity; |

| Dimension(L*W*H): | customize; | Mixing cycle time: | 5-8 Minute; |

| Condition: | New; | Packaging Detail: | (1)FCL: export equipment standard container (2) wooden box: The size of the packing box shall be designed according to the equipment The widget is attached to the machine Soft wood is placed in front or back of the machine to protect it. The plastic film is covered in this machine for waterproofing The equipment into the container with the crane; |

| Power(W): | 93KW; | Weight: | customize; |

| Supply Ability: | 100 Set/Sets per Month; | tile gule: | Semi-Auto Dry Mix Plant; |

| Warranty: | 1 YEAR; | Packing capacity: | 10t/h; |

| After-sales Service Provided: | Field installation, commissioning and training,Field maintenance and repair service,Free spare parts,Online support,Video technical support,Engineers available to service machinery overseas; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| Productivity: | 10 ton per hour; | Certification: | CE/CV/BO/ISO; |

| Mixing power: | 18.5kw; | Application: | dry mortar produce; |

Fire fighting material mixing machinery production line

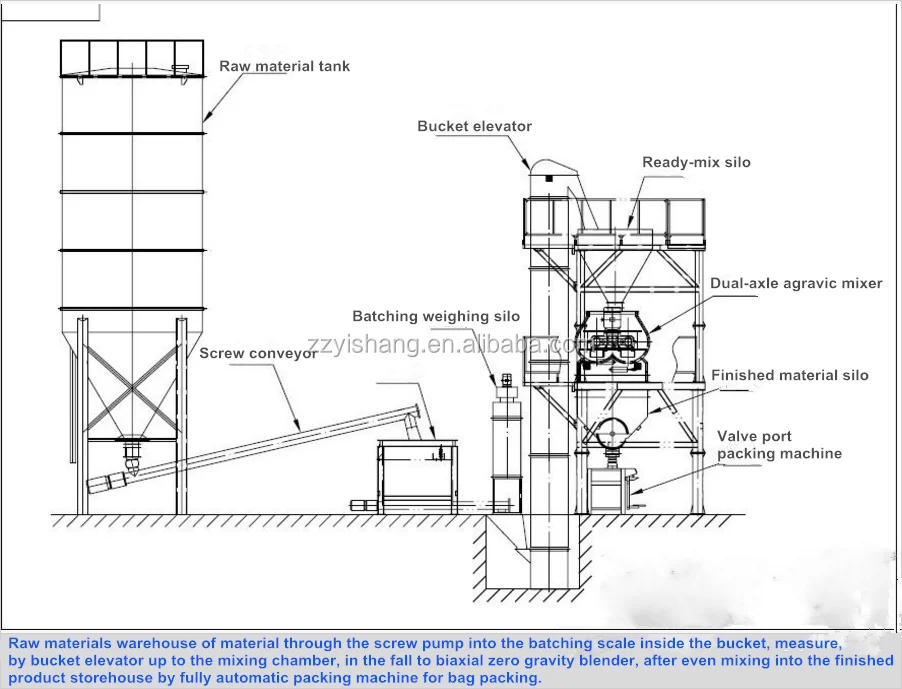

Automatic dry mortar production line process flowchart

1-3 Raw material silo 4 Bucket elevator 5 Screw conveyor

6 Batching weighing silo 7 Chain hoist 8 Double shafts without gravity mixer

9 The finished product warehouse 10 packing machine

Mode | Capacity | Area | Height | Note |

Simple | 1-5t/h | 40square meter | 3m | Manual batching and packing |

Basic | 5-15t/h | 40-60square meter | 6-10m | Manual batching ,automatic packing |

Semi Automatic Serial | 5-15t/h | 40-80square meter | 8-12m | Automatic batching of coarse material,manual batching of additive automatic packing |

Full Automatic | 5-50t/h | 40-100square meter | 10-25m | Automatic batching of coarse material,manual batching of additive automatic packing |

Full Automatic Tower | 55~100t/h | 60~500square meter | 10-30m | Automatic batching of coarse material,manual batching of additive automatic packing |

(1)FCL: export equipment standard container

(2) wooden box: The size of the packing box shall be designed according to the equipment

The widget is attached to the machine

Soft wood is placed in front or back of the machine to protect it.

The plastic film is covered in this machine for waterproofing

The equipment into the container with the crane

Pre-sales service:

Design - discuss (email/phone/chat tools) - provide solutions - access invitations and receptions - create major trust - contracts;

Sales service:

Send confirmation design and foundation drawings to customers;

Provide customers with photos and videos of the production process;

Pre-assemble the main components of the machine and test them;

Draw color and logo according to customer's requirement;

Arrange customers to check the finished products;

Pre-order logistics locations to ensure on-time delivery.

Monitor the loading and packing machine in the container, such as the packing of wooden cases, steel wire reinforcement.

After-sales service:

Tracking ship and estimated date of arrival;

Send all necessary documents and assist to retrieve the goods smoothly;

Dispatch experienced engineers to installation and commission, training;

Regular learning of equipment operation;

Remote control is readily available;

Guarantee: 12 months;

Spare parts: sent by DHL/fedex/TNT.

-

Cheap dry mortar mixer from China with high productivity

-

hot sale dry cement mixer for mixing sand and cement / automatic dry mortar production line equipment

-

Sincola Ready Mixed Gypsum Cement Tile Adhesive Mixer Glue Production Line

-

Toolmore 100 Liter Portable Concrete Mortar Mixer

-

cement sand mixing bagging machine cement mortar mixer

-

Simple caulk mixer production line

-

Low investment and high efficiency simple dry powder mortar production line

-

Small business tile adhesive machine price

-

Simple dry powder mortar production line cement mortar mixer wall putty mixing equipment tile glue making machine

-

Energy-saving equipment cement mortar mixing line mixer price

Other Products

-

$2000.00 / set

$2000.00 / set -

$4980.00 / set

$4980.00 / set -

$4900.00 / set

$4900.00 / set