QC11 K shearing machine die cutting blade

-

Supplier: Nanjing Harsle Machine Tool Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr HARSLE MACHINE -

Price: $400.00 /piece -

Min. Order: 1 piece

| Material: | CARBON; | Place of Origin: | Jiangsu China; |

| Applicable Industries: | Manufacturing Plant,Food & Beverage Factory,Construction works ,Energy & Mining; | Port: | shanghai; |

| Payment Terms: | L/C,T/T; | Brand Name: | Harsle; |

| Type: | Forging Parts; | Supply Ability: | 1000 Piece/Pieces per Week; |

| Packaging Detail: | standard package; |

guillotine shearing blade for mechanical cutting machine

Quality assurance:

1.The choice of materials(for the toughness and abrasion resistance required by customers to choose the appropriate material)

Chemical composition of product have high quality and scientific control curve.In addition to conventional elements,we add a moderate precious and rare element for the balde material . For the fast and accurate detection and adjustment of chemical composition,our company has invested large amounts of funds in the laboratory equipment to ensure the desired target value of the product.

2.Forging

By forging the product can be removed cast defects appear in the smelting process like osteoporosis and optimized microstructure. Because of saving a complete flow line,the forging material have a better machanical properties than the same material. Except rolled sheet,profiles or welded parts that are simple shapes available,the important parts that need high mechanical load and grim working conditions are used the forging.

3.Advanced heat treatment process

Heat treatment process is a very important step to ensure and improve product quality. Only through advanced heat treatment equipment and heat treatment process,is the blade able to have a good quality.

Our company has a set of advanced heat treatment equipment and can ensure the workpiece within a specific time and a certain range of process to transform.

4.Machining

With the requirements of precision sheet metal processing improving,we have developed an ultra-high-precision cutting tools,and only precision milling tool accuracy has been able to match±0.002mm thickness tolerances and Ra0.1μm surface roughness are our regular standards. Using our specific technology and expertise, we also can meet customer's higher tolerance requirements such as about thickness,parallelism,flatness,outer and inner circles. We now have been able to ensure that the thickness tolerances up to ±0.002mm for certain inner circle, their tolerance can be achieved H3. Checking all precision products are carried out in a heated indoor.

Technical Parameters

Shearing blades picture

-

Anode Yoke for aluminium smelter

-

Sow mould for aluminium smelter

-

Metal cutting shear blades for cut-to-length wire

-

Ice cream machine accessories, soft ice cream machine valves, spare parts for soft ice cream machine

-

Powder Metallurgy gear powder metal parts china sprocket

-

Precision manufacturing of industrial hot rolling rolls

-

Metal Injection Molding Metallurgy High Precision Metal Parts for Sports Running Signal Equipment Accessories

-

Factory Supply OEM Custom Manufacturing Service Powder Metallurgy Die Mim Small Stamping Parts

-

Condenser Parts Rocker Arm Ice Cream Maker Mixer

-

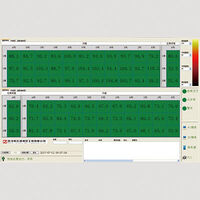

BPS-K600 Continuous Casting Mold Breakout System

Other Products

-

$11000.00 / set

$11000.00 / set -

$800.00 / set

$800.00 / set -

$21400.00 / set

$21400.00 / set -

$26000.00 / set

$26000.00 / set -

$400.00 / set

$400.00 / set -

$100.00 / set

$100.00 / set