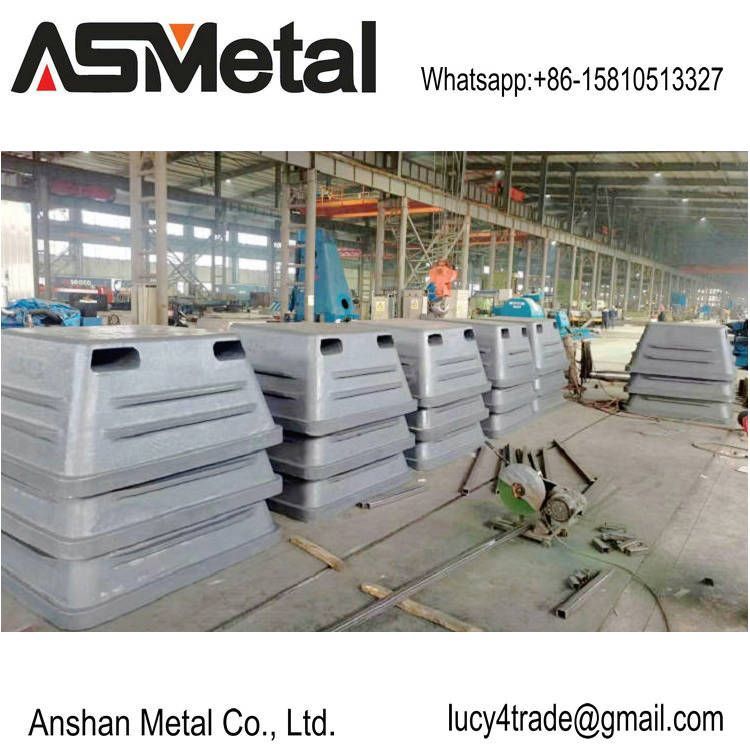

Sow mould for aluminium smelter

-

Supplier: Anshan Trader -

Region: China -

Contact: Mr Lucy Lu -

Price: $1000.00 / 1 - 500 pieces -

Min. Order: 1 piece

Creating a sow mold for an aluminum smelter involves several important steps and considerations to ensure quality and efficiency in the casting process. Here's an overview of the typical process:

1. **Design of the Sow Mold**

- **Material Selection**: Choose a material that can withstand high temperatures and is compatible with aluminum. Common materials include steel, iron, or specially developed alloys.

- **Dimensions**: The mold should be designed based on the desired size of the sows, which are typically large blocks of aluminum for transport and storage.

- **Cooling Features**: Incorporate cooling channels or features to help solidify the aluminum quickly and uniformly.

2. **Mold Fabrication**

- **Machining**: Use appropriate machining techniques (CNC milling, lathing, etc.) to create the precise shape of the mold based on the design specifications.

- **Finishing**: Smooth the interiors of the mold to minimize surface defects on the aluminum sows.

3. **Preparation for Casting**

- **Cleaning**: Ensure the mold is free of any debris, oil, or contaminants before use.

- **Release Agents**: Apply a release agent if necessary to facilitate the easy removal of the sows after solidification.

4. **Casting Process**

- **Pouring**: Melt aluminum is poured into the mold at the appropriate temperature (typically around 660°C/1220°F for aluminum).

- **Control**: Monitor the pouring rate to ensure the mold is filled uniformly, preventing defects.

5. **Cooling and Solidification**

- Allow the aluminum to cool and solidify within the mold. The cooling rate can affect the mechanical properties of the final sow.

- **Time Management**: Control cooling time to avoid thermal shocks that could crack the mold or the aluminum.

6. **Demolding**

- Once solidified, remove the sow from the mold. Use lifting equipment if the sow is heavy.

- Inspect the sow for defects or any surface imperfections.

7. **Post-Processing (if necessary)**

- Depending on the end-use of the aluminum, additional processing may be required, such as trimming, cleaning, or surface finishing.

8. **Quality Control**

- Test the final product to ensure it meets industry standards and specifications, checking for composition, dimension, and surface quality.

Safety Considerations

- Ensure that all safety protocols are followed regarding high-temperature operations.

- Wear appropriate personal protective equipment (PPE) and utilize safety equipment to handle molten metal.

Environmental Considerations

- Implement proper waste management practices to handle any byproducts or waste generated during the casting process.

This overview provides a foundational understanding of how to create and utilize a sow mold in an aluminum smelter. Depending on the specific requirements of the operation, the process may vary or require additional steps.

-

Anode Yoke for aluminium smelter

-

Metal cutting shear blades for cut-to-length wire

-

Ice cream machine accessories, soft ice cream machine valves, spare parts for soft ice cream machine

-

Powder Metallurgy gear powder metal parts china sprocket

-

Precision manufacturing of industrial hot rolling rolls

-

Metal Injection Molding Metallurgy High Precision Metal Parts for Sports Running Signal Equipment Accessories

-

Factory Supply OEM Custom Manufacturing Service Powder Metallurgy Die Mim Small Stamping Parts

-

Condenser Parts Rocker Arm Ice Cream Maker Mixer

-

BPS-K600 Continuous Casting Mold Breakout System

-

Handheld Thermocouple Calibrator

Other Products

-

$500.00 / piece

$500.00 / piece