double layers metal sheets roofing machine, tile making machine Corrugated and Trapezoid Roofing Tile roll forming Machine

-

Supplier: Cangzhou Zhongtuo International Trade Co., Ltd. -

Region: Hebei, China -

Contact: Mr Cary xu -

Price: $14500.00 /set -

Min. Order: 1 set

| thickness of material: | 0.3-0.8mm; | Shaft material: | High Grade No.45 Forged; |

| Key Selling Points: | Easy to operate; | Use: | ROOF; |

| volatage: | 380V,50Hz, 3phrase or as your requirement; | Warranty: | 1 YEAR; |

| Control system: | Delta Inverter; | width of material: | as customers requied; |

| Certification: | ISO9001 and CE; | Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory,farms,restaurant,HOME USE,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; |

| Usage: | Roof Profile; | Payment Terms: | D/A,D/P,T/T; |

| Product name: | metal tile roll forming machine; | After-sales Service Provided: | Online support,Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Engineers available to service machinery overseas; |

| Production Capacity: | 10-12m/min; | Language: | English;Russian;Chinese; |

| Port: | Tianjin; | Packaging Detail: | Naked; |

| Type: | Tile Forming Machine; | Tile Type: | STEEL; |

| Brand Name: | Zhongtuo; | Condition: | New; |

| Voltage: | 380V or as required; | Dimension(L*W*H): | 8.5*1.65*1.5m; |

| Weight: | 6.5T; | workable material: | aluminum sheet, iron sheet, galvanized sheet; |

| Place of Origin: | Hebei China; |

China double layers metal sheets roofing machine, Corrugated and Trapezoid Roofing Tile roll forming Machine

metal sheets roofing machine, customized design

corrugated roll forming machine, 18month guarantee period

trapezoid roofing tile roll forming machine, good after-sell service

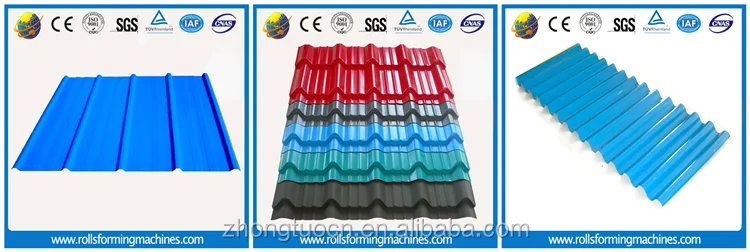

for this double layer metal sheets roofing machine, you can choose corrugated and trapezoid type, also can choose IBR and wave type,by this design, can save space and cost, but kindly note one thing: both layers cannot run at same time

Finished product of China double layers metal sheet Roofing Machine:

Materials of corrugated metal sheets roofing tile roll forming machine:

Processing material: colored steel coils, galvanized coils, or aluminum coils

Material thickness: 0.3- 0.8 mm

Coil width within 1500mm

Forming speed: 8-12 m/min or as your requests

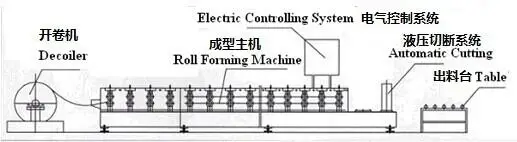

Production process of trapezoid metal sheets roofing tile roll forming machine

Uncoiling→Feeding material into machine→Roll forming→Measuring length→

Auto cutting→Products receiving

Components of China double layers metal sheets roofing machine, Corrugated and Trapezoid Roofing Tile roll forming Machine:

No. | Name | Unit | Qty |

1 | Decoiler | set | 1 |

2 | Main forming machine | set | 1 |

3 | PLC control system | set | 1 |

4 | Hydraulic pump station | set | 1 |

5 | Post cut | set | 1 |

6 | Electric motor | set | 1 |

7 | Output table | set | 1 |

Detailed introduction of every part for this China double layers metal sheets roofing machine, colored steel Roofing Tile roll forming Machine

1.Un-coiler System of China double layers metal sheet Roofing Machine

Usage: It is used to support the steel coil and uncoil it in a turntable way.

Passive uncoil pulled by roll forming system

Loading capacity | Uncoiling width | Inner diameter |

5T | 1200mm | 450-550mm |

2. Coil feeding part of China double layers metal sheet Roofing Machine:

Usage: Put the raw material(steel plate) through the beach to manufacture and process,it can guarantee that the products are neat,parallel and everything is uniformity.Please refer to the equipment regulation to know the function of locate angle iron.

3. Main Roll Forming System of corrugated roofing tile roll forming machine

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive,chain transmission,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is working.

Feature : Ensure stability , precision and lifetime.

No. | Main parameter | |

1 | Length of the main part | About 8500*1650*1500mm |

2 | Weight of main part | About 6.5 t |

3 | Voltage | 380V/50HZ3Phase (as customer`s request) |

4 | Roller fixer | Middle plate welded |

5 | Frame | 350 H steel welded |

6 | Frame thickness | 20mm |

7 | Drive mode | Chain |

8 | Material of rollers | 45# steel, surface hard chromium plating. |

9 | Material of shafts | 45# steel |

10 | Diameter of shafts | Φ80mm |

11 | Number of rollers | Up layer: 13 rollers Down layer: 15 rollers |

14 | Main power | 5.5kw |

4. Cutting device of trapezoid metal sheets roofing tile roll forming machine

Advanced hydraulic drive, automatic punching and cutting after forming, no distorting or wasting, high level safety factor.

(include cutting tools, hydraulic tank, cutter machine)

Blade Material | Cutting system |

Cr12 quenched | Full automatic |

5. Counter of corrugated metal sheets roofing tile roll forming machine

One counter gauges length, pulses, and decides length. Omron encoder for length measurement.

6.Products receiving tables of trapezoid metal sheets roofing tile roll forming machine

1. It adopts welded steel and supported roller to transmit the products.

2. 3*0.9*0.6m

7. Controlling device of corrugated metal sheets roofing tile roll forming machine

1) Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with

stability, precision and lifetime.

2) Other electric element are Delta

3) Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety.

| Screen | PLC |

| Text screen displayer | Taida DVP14ES from Taiwan |

8. Hydraulic system of trapezoid roofing tile roll forming machine

(include a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes. And two sets of electromagnetism valves )

Origin | Power |

Advanced hydraulic system from Taiwan | 3kw |

Spare parts ( for free)

1. Easy damaged parts: conk 2 pcs, fuse-link 4 pcs;

2. Rubber mat 1 pcs;

3. Bolt spanner 1 pcs

Remarks

Payment terms | 30% T/T in advance and balance 70% after inspection confirmation before shipment. |

Delivery | within 30 working days after receipt of deposit. |

Packing | Nude packing with 1*40GPcontainer |

Warranty | One year, and we will provide the technical support for the whole life. |

Installation | 1.Training: the buyer should charge of visa, return ticket, food and accommodation overseas and USD50/person/day for salary. 2. Need one technician 3. Training time: one week (contains the time of installation and adjustment) |

More details, feel free to contact me by Mobile: +8613785755431(what's app/viber)

Packing

1. one 40ft container for loading one set machine with manual decoiler;

2. the whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

Q: Are you manufacturer?

A: Yes, we are manufacturer and trading company.

Q: What kind of payment term you can do?

A: We are flexible about payment terms, please contact us for details.

Q: What info you need before you make the proposal for a roll forming machine?

A: The profile drawings, material informations, your special requirements.

Q: What I should do if I just start to know roll forming machinery?

A: Contact us immediately, we provide free consultant pre-sales service.

Q: How to visit our company:

A: 1.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

2.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),then we can pick up you.

3. Fly to Guangzhou aiport: By air From Guangzhou to Beijing airtpot; By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

More this type machines for your reference:

if you have any interest on our machines, just contact me :

-

Three-layer molding machine

-

Low cost clay brick making machine manual type clay brick making machine suitable for different sizes and different types of bricks

-

1000 type roof panel glazed tile pressing machine

-

HMS900 Electric Tile Cutter with CE Certification 1000mm Cutting Length, Marble Saw

-

Sheet metal building materials manufacturing machinery parts

-

Wall and color steel tile type polyurethane sandwich roof panel manufacturing machine

-

Terrazzo brick press

-

2022 Popular Manual Clay Roof Tile Making Machine Floor Tile Making Machine Roof Floor Tile Press Forming Machine

-

Galvanized floor deck forming machine

-

Automatic metal Ibr shingle trapezoidal shingle roller press machine for sale in South Africa

Other Products

-

$70000.00 - $85000.00 / set

$70000.00 - $85000.00 / set -

$20000.00 / set

$20000.00 / set -

$5000.00 / set

$5000.00 / set -

$15000.00 - $23000.00 / set

$15000.00 - $23000.00 / set -

$27800.00 - $29800.00 / set

$27800.00 - $29800.00 / set -

$20000.00 / set

$20000.00 / set -

$2500.00 / set

$2500.00 / set -

$24000.00 / set

$24000.00 / set -

$14000.00 / set

$14000.00 / set -

$10000.00 / set

$10000.00 / set