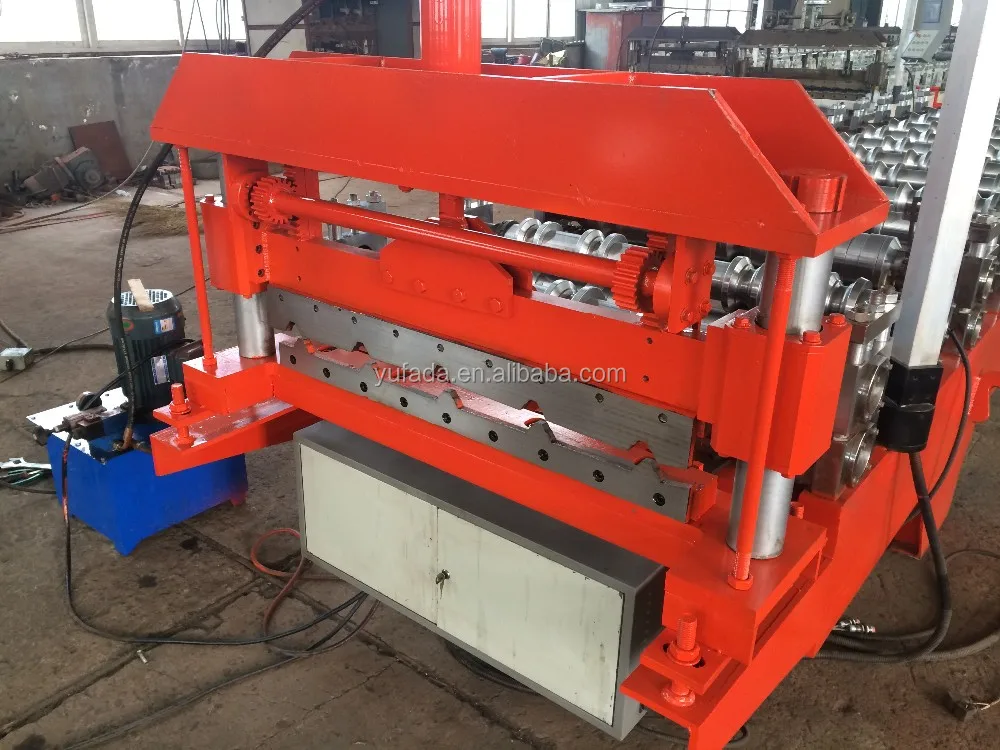

YUFA 2020 840 galvanized corrugated roofing sheet making machine manual roof tile zinc making machine

-

Supplier: Tianjin Yufada Industry Co., Ltd. -

Region: Tianjin, China -

Contact: Mr Ted Li -

Price: $10000.00 /set -

Min. Order: 1 set

| Warranty: | 1 Year; | Voltage: | 380V 50Hz 3phases; |

| Raw material thickness: | 0.3-0.8mm; | Rolling thinckness: | 0.3-0.8mm; |

| Core Components: | Pressure vessel,Motor,Bearing,Gear,Pump,Gearbox,Engine,PLC; | Control system: | Taiwan Delta; |

| Product name: | 840 roof panel roll forming machine; | Raw material: | PPGI/Galvanized sheet; |

| Warranty of core components: | 1 Year; | Packaging Detail: | packed with waterproof cloth and card board in container; |

| Dimension(L*W*H): | 3-7.5m*1.3m*1.3m; | Video outgoing-inspection: | Provided; |

| Showroom Location: | none; | Applicable Industries: | Building Material Shops; |

| Feeding width: | 1000mm,1250mm; | Key Selling Points: | Easy to Operate; |

| Payment Terms: | L/C,T/T; | Power: | Hydraulic; |

| Supply Ability: | 30 Set/Sets per Week; | Brand Name: | YUFA; |

| Local Service Location: | none; | Type: | Tile Forming Machine; |

| Use: | Wall,ROOF; | Machinery Test Report: | Provided; |

| Certification: | Any the customer need; | Tile Type: | Glazed Steel, Colored Steel,Steel; |

| Automation: | Automatic; | Port: | Tianjin; |

| Place of Origin: | CN;TIA; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Weight: | 3-5 tons; |

| Condition: | New; | Marketing Type: | New Product 2020; |

| Production Capacity: | 8-12 m/min; |

YUFA 2020 840 galvanized corrugated roofing sheet making machine manual roof tile zinc making machine

Welcome to YUFADA, we are your roof roof panel metal roof panel corrugated panel roll forming equipment maintain expert.

Home Products categories Company profile Contacts

Now our roof roof panel metal roof panel corrugated panel roll forming equipment have been exported to many countries, the most important is that all you need can be customized.

Click here for machine quote and working video

If u want to see the machine working video, please contact with Jessica with any way below.

Wechat/whatsapp: +86 16632721313

Manual uncoiler-- roll forming machine-- PLC control box-- hydraulic system- output table

| Article No. | Item Name | Specification |

| 1 | Width of feeding material | 1000 mm coil sheet |

| 2 | Thickness of feeding material | 0.3-0.8 mm coil sheet |

| 3 | Roller station | 13 stations |

| 4 | Shaft Diameter | 75 mm |

| 5 | Productivity | 8-15 m/min |

| 6 | Rollers' material | 45# steel with 0.05mm chrome |

| 7 | Shaft material | 45# steel with 0.05mm chrome |

| 8 | Weight | 6.5 tons |

| 9 | length | 6.5 m |

| 10 | Voltage | 380V 50Hz 3phases |

| 11 | Control | PLC |

| 12 | Decoiler | 5 tons |

| 13 | Motor | 7.5 kw |

| 14 | Driving way | Chain transmission |

| 15 | Chain size | 0.6-2 inch |

| 16 | Cutting system | Hydraulic cutter |

YuFaDa industrial CO.,Ltd is a professional manufacturer designing and producing roll forming machines established in June 1996. We have four factories working in Beijing, Tianjin and Hebei province. More than 400 workers provide service for u.

Products mainly include trapezoidal steel roof/wall panel machine, C&Z shape purline machine, high-way guardrail machine, sandwich panel production line, deck forming machine, C U L light keel machine, shutter slat door forming machine, cutting machine, downpipe machine, gutter machine, etc.

1. Free technical support and free accessories supply.

2. Engineer available to service machinery overseas.

3. One year warranty is provided.

4. Long life technical guidance for free.

5. We always offer technical support, quick response, all your inquire will be replied in 24 hours.

1. Q: How to visit our company:

A: Fly to Beijing Airport: By fast train From Beijing South station to Cangzhou west station

(1hour), then we can pick up you to factory(40min).

Fly to Shanghai Airport: By fast train From Shanghai Hongqiao station to Cangzhou west

station(4.5 hours), then we can pick up you to factory(40min).

2. Q: What should I provide if I want to customized machine?

A: U need provide profile drawing, material, thickness, voltage and your special requirements.

3. Q: What is the Warranty?

A: Within 12 mounts, all technicals are ready to serve you at any time.

4. Q: What can you do if the machine broken?

A: Our machine's warranty period is 12 months, if the broken parts can't repair, we will send

new parts replace the broken parts free, but you need pay the express cost if after warranty period. we can negotiate to solve the problem, and we supply the technical support for whole life of equipment.

5. Q: If need technician to workshop to debug and teach, how to do?

A: We sent technician to your country to fix the machine. Buyer should bear cost including: visa, round trip ticket and suitable accommodation, also buyer should pay the salary 100 USD/day.

Click here for machine quote and working video

-

Three-layer molding machine

-

Low cost clay brick making machine manual type clay brick making machine suitable for different sizes and different types of bricks

-

1000 type roof panel glazed tile pressing machine

-

HMS900 Electric Tile Cutter with CE Certification 1000mm Cutting Length, Marble Saw

-

Sheet metal building materials manufacturing machinery parts

-

Wall and color steel tile type polyurethane sandwich roof panel manufacturing machine

-

Terrazzo brick press

-

2022 Popular Manual Clay Roof Tile Making Machine Floor Tile Making Machine Roof Floor Tile Press Forming Machine

-

Galvanized floor deck forming machine

-

Automatic metal Ibr shingle trapezoidal shingle roller press machine for sale in South Africa

Other Products

-

$10000.00 / piece

$10000.00 / piece -

$6000.00 / set

$6000.00 / set -

$1000.00 / set

$1000.00 / set