Good Performance 160TPH Asphalt Mixing Plant Price SAP160

-

Supplier: Zhengzhou SINOSUN Machinery Co., Ltd. -

Region: Henan, China -

Contact: Ms Sinosun Li -

Price: $400000.00 /set -

Min. Order: 1 set

| Packaging Detail: | Good Performance 160TPH Asphalt Mixing Plant SAP160 is packed by 15 units 40HQ containers.; | Dimension(L*W*H): | 40*40*17m; |

| Condition: | New; | Showroom Location: | Egypt,Philippines,Peru,Russia,Thailand,Colombia,Malaysia,Morocco; |

| Product name: | Good Performance 160TPH Asphalt Mixing Plant Price SAP160; | Machinery Test Report: | Provided; |

| Warranty of core components: | 1 Year; | Local Service Location: | Egypt,Philippines,Saudi Arabia,Russia,Thailand,Malaysia,Morocco; |

| Electrical Control: | Germany (SIEMENS); | Supply Ability: | 5 Set/Sets per Month 160TPH Asphalt Mixing Plant Price; |

| Weight: | 50-130T; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Paypal; |

| Asphalt Plant Power: | 340KW; | Core Components: | PLC,Gearbox,Motor,Gear,Pump; |

| After-sales Service Provided: | Video technical support,Online support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Voltage: | 220V/380V-50Hz; | Oil Burner: | Italy (EBICO); |

| Warranty: | 1 Year; | Port: | Qingdao, Tianjin, Shanghai, China; |

| Color: | Client's Customized; | UNIQUE SELLING POINT: | High operating efficiency; |

| Package Preview: | ; | Certification: | ISO9001,CE,EAC; |

| Usage: | Asphalt Pavement Maintenance; | Place of Origin: | Henan China; |

| Applicable Industries: | Building Material Shops,Manufacturing Plant,Construction works ; | Power: | 360kw; |

| Video outgoing-inspection: | Provided; | Working Noise: | 70db(A); |

| Asphalt Mixer: | 2000 kg/batch; | Marketing Type: | New Product 2020; |

| Control: | Remote Diagnose & Monitoring; | Mixing Type: | Hot Mix; |

| Brand Name: | SINOSUN; |

Good Performance 160TPH Asphalt Mixing Plant Price SAP160

SAP160 160 tons asphalt plant adopts modular structure, reasonable layout, simple and compact structure, suitable for container transportation, installation demolition convenient.

Components of SAP160 160 tons asphalt mixing plant

Cold Aggregate Feeding System

1.SAP160 Asphalt Mixing Plant consists of 4 units of cold aggregate bins. Each cold aggregate bin includes one set of variable speed discharge belt feeder.

2.There is one set of alarming device in each cold aggregate bin in case of no aggregates supplying during operation.

3.The belt feeder adopt variable speed to discharge the aggregates.

Drying System

1.The drying drum adopts four wheel friction to work.Motor is started by reducing voltage, insulating layer adopted in outside of drying drum. And drying surface is packaged by stainless steel.

2.Cylinder and ejecting blade of heat-resisting steel manufacturing, longer life.

3.The drying system and mixer motor adopt the German Nord brand,ensure the long-term stable operation of the drum and the mixer.

4.The burner is equipped with the Italy Ebico brand burner, which can burn completely, the flame is stable and the weighing sensor adopts the American Mettler Toledo brand to ensure accurate measurement of stability.

Mixing Tower

1.The vibrating adopts four layer’s design. The outside of screen is closed by protective cover, so that dust won’t going out from the screen.

2.Uniaxial external structure make the maintenance work more convenient.

3.Hot aggregate storage bin has level indicator,the hot aggregate storage bin has big volume so that feeding aggregates will be more stable.

4.Aggregate weighing system and filler weighing system all have anti-dust device.

Hot Aggregate Elevator

1.The hot aggregate elevator adopts flat link chain to drive, the chain bucket has protective device.

2.The non-return device adopted in drive wheel can prevent the chain from reversing.

Dust Collecting System

1.Adopting primary dust collecting by gravity, secondary dust collecting by water filter dust collecting design,which is more environmentally friendly.

2.The bulky grain can be recycled after primary dust collecting.

3.The dust can be discharged or reused after secondary dust collecting,higher environmental standards.

Electrical Control

1.We adopt famous international brand (like SIEMENZ, Schneider, ABB) electronic elements, working performance is reliable and stable.

2.The adoption of PLC and Industrial computer make the operation more easy.

3.The Multifunctional printer can print and storage date anytime.

4.Big capacity formula function can meet client’s various need.

5.Optional remote fault detection.

6.Container type control room, strong and durable, economy and beautiful.

7.The Manual/automatic operation can be shifted freely.

Technical parameter of SAP160 160TPH Asphalt Mixing Plant

|

Capacity |

SAP160 |

|

160t/h |

|

|

Max capacity of oblique belt machine |

Width 600mm |

|

160t/h |

|

|

Max capacity of dry roller( mm) |

1800×8000 |

|

160t/h |

|

|

Max burning amount of burner |

Coal burner |

|

2000kg/h |

|

|

Filtrating area of bag dust collector( m2) |

Pulse Jet |

|

480 |

|

|

Recycling screw conveyor |

13.5t/h |

|

Blower |

900m3/(m) |

|

Flue pipe( mm) |

1200×10000 |

|

Max. capacity of hot aggregate elevator |

Chain elevating |

|

160t/h |

|

|

Max. capacity of vibrating screen |

160t/h |

|

Interval capacity of hot aggregate hopper |

4 interval type |

|

Weighting device |

Remote display of electronic gauge) |

|

Aggregate:±0.3% |

|

|

Bitumen :±0.15% |

|

|

Fine aggregate:±0.3% |

|

|

Mixer |

Double-axis forcing stirring batch |

|

Single-unit drive 1500kg/lot |

|

|

Discharging amount of bitumen injector |

Self-flow |

|

500L/min |

|

|

Max. capacity of filler elevator |

Hopper elevating |

|

15t/h |

|

|

Spiral conveyor |

20t/h |

|

Operating panel |

Computer display |

|

Drive panel |

Indoor type |

|

311kw |

|

|

|

| 40-400TPH Stationary Asphalt Plant | 40-160TPH Mobile Asphalt Plant | 20-120TPH Drum Mix Asphalt Plant |

|

|

|

| 6-10TPH Emulsion Bitumen Plant | 4-10 TPH Bitumen Melting Machine | Bitumen Tank for Asphalt Plant |

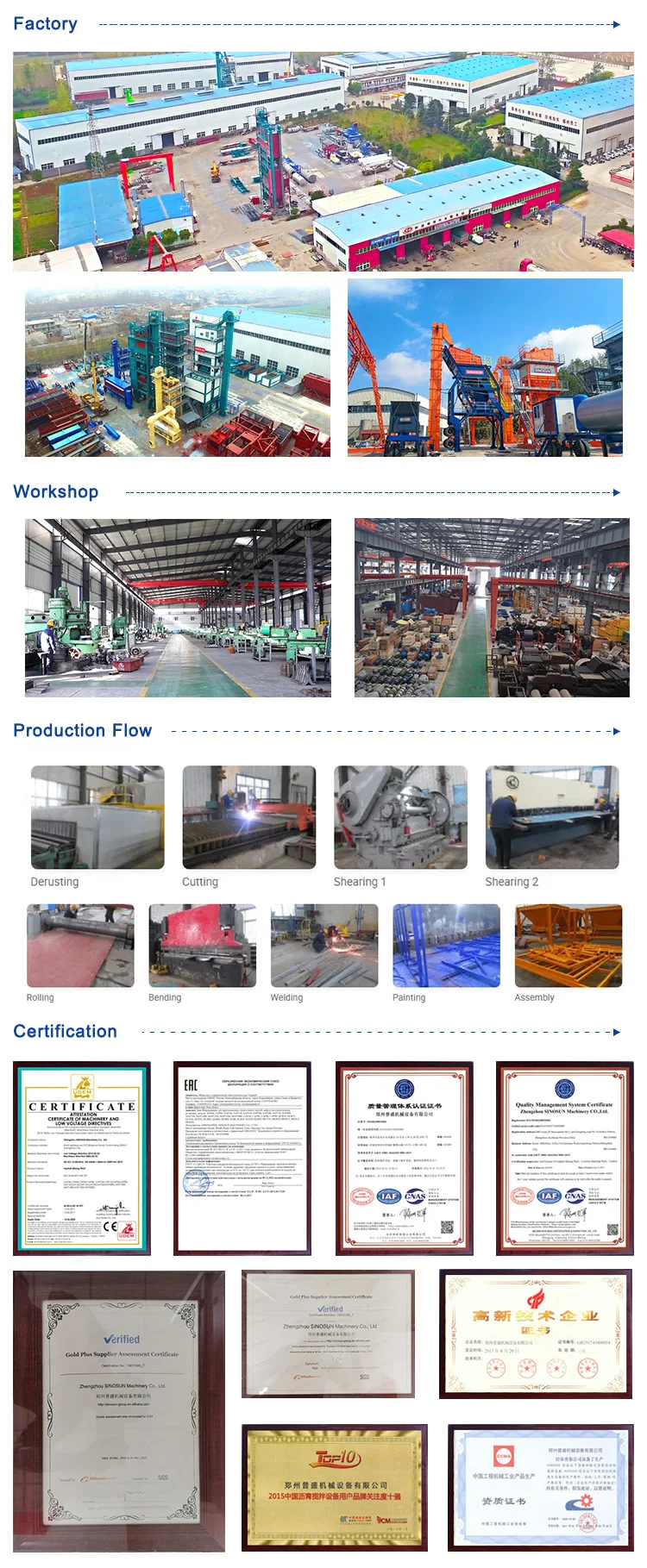

For over years, we supplied the asphalt industry with high quality asphalt batching plant parts, mobile asphalt mixing plant,continous asphalt mixing plant and other reletaed products.

Our asphalt plant products are cost effective, user friendly, easy to maintain and strong after - sales services.

Now these asphalt plant products have been widely used in home and abroad road construction project, such as Russia, USA,Thailand, Romania , Poland , Brazil , Philippines , Indonesia, Peru, Canada, Bangladesh etc. In Africa , we have exported to Ethiopia , Angola , Algeria and Libya etc.

SINOSUN is one of China’s dominant and professional manufacturers and exporters of Precisioned Asphalt Mixing Plants and related asphalt plant equipment.

We mainly supply:

1.Stationary asphalt mixing plant (SAP series)

2.Recycle asphalt mixing plant (SR series)

3.Mobile asphalt mixing plant ( MAP series)

4.Continuous asphalt mixing plant (CAP series)

5.Twin-shaft asphalt mixing plant (QLB series)

6.Twin-drum asphalt mixing plant (SLB series)

7.Emulsion Bitumen Plant (RH series)

8.Bitumen Melting Machine (DT series)

Q:Which countries your equipment have been exported?

A:Thailand, Philippines, Indonesia, Myanmar, Russia, Bangladesh, Kazakhstan, Uzbekistan, Russia, Romania, Somalia, Kenya, Malawi, Nigeria, Togo, Mozambique, Oman, South Africa, America, Peru, Chile, Colombia, Venezuela, Australia, etc.

Q:How many workers are needed to operate one set of asphalt plant?

A:1 loader operator, 1 mechanical, 1 electrician, 1 supervisor ,1 the operator of the whole plant.

Q:How many days are used for installation of one set asphalt plant?

A:Around 20-30 days, according to local situation.

Q:Do you provide overseas erection and training service?

A:Yes, we can send experienced engineers to your country, guide erection and commissioning and train your workers how to operate the plant.

Q:How long is the delivery time?

A:30-40 days, according to different configuration. We promise to delivery on time.

Q:Can you sent me some spare parts freely?

A:Some spare parts will be sent to you together with asphalt plants freely.

Q:How to go to your asphalt plant factory easily?

A:Our city has airport. If by air, you can fly from Guangzhou/Beijing/Shanghai no more than 2 hours. Also you can fly to Zhengzhou, we send car to pick you up there.

Q:Can I visit your factory?

A:Of course. We warmly welcome you to visit our factory. And we provide you great services like airport pick up, hotel booking, etc.

Q:How long is the warranty of your asphalt plant?

A:12 months

Q:What payment terms you accept?

A:We accept T/T, L/C,D/A,D/P, Western Union, MoneyGram and other ways according to the practical situation.

Get the quotation of asphalt mixing plant, welcome contact us at any time.

Pls following us for more information of asphalt plant and related equipment.

-

40TPH Mobile Asphalt Mixing Plant

-

Portable asphalt mixer asphalt hot recycling production pavement repair vehicle

-

Jinwang small mobile asphalt mixer road construction machinery concrete mixer

-

China famous brand 1650KG mixing capacity asphalt mixing plant SLB1500X8 for sale

-

Sell second-hand NIKKO NB1600 asphalt mixing plant

-

Mini Portable Cold Asphalt Mixer / Asphalt Mixing Plant Price / Asphalt Drum Mixing Plant 10t/h

-

asphalt mixer, asphalt mixer for mixing plant

-

UNUQUE GROUP Production 80TPH Mobile Asphalt Plant For Sale

-

20T/H - 100T/H Hot Mixing Plant Drum Mixing Asphalt Plant For Sale Continuous Asphalt Plant Price Mobile Asphalt Mixing Plant

-

LB2000 160t/h Asphalt Mixing Plant

Other Products

-

$10000.00 / set

$10000.00 / set -

$50000.00 / set

$50000.00 / set -

$150000.00 / unit

$150000.00 / unit -

$35000.00 / set

$35000.00 / set -

$45000.00 / set

$45000.00 / set -

$250000.00 / set

$250000.00 / set -

$10000.00 / set

$10000.00 / set -

$30000.00 / set

$30000.00 / set -

$45000.00 / set

$45000.00 / set -

$200000.00 / set

$200000.00 / set