make cardboard boxes automatic carton corrugated slotting machine fully automatic corrugated making carton packaging box machine

-

Supplier: Qingdao Aopack On Demand Packaging Co., Ltd. -

Region: Shandong, China -

Contact: Ms. Anna Qin -

Price: $79000.00 /set -

Min. Order: 1 set

| Packaging Detail: | Before the machine is packed in a wooden box, we will apply oil to the machine and wrap the protective film to avoid moisture and rust during the transportation of the machine and to ensure that the machine is in the best condition when it reaches the customer. We will use the fumigation-free glued wood board to make the most suitable packaging for the product, preventing the machine from rusting and unnecessary collision during transportation.; | After-sales Service Provided: | Free spare parts,Video technical support,Field installation, commissioning and training,Field maintenance and repair service,Online support; |

| Product name: | Automatic short run cardboard box making machine; | Supply Ability: | 3 Set/Sets per Month; |

| Processing Type: | Creasing,slitting,cutting; | Certification: | CE; |

| Weight: | 2200kg; | Packaging Material: | Fumigation free plywood; |

| Voltage: | 220V/230V; | Function: | Cardboard rigid box making; |

| Condition: | New; | Type: | Carton slotting; |

| Place of Origin: | Shandong China (Mainland); | Production Capacity: | 400pcs/hour; |

| Power(W): | MAX2.5kW; | Payment Terms: | L/C,T/T; |

| Product Type: | Box Making Machine; | Warranty: | 1 Year; |

| Port: | Qingdao Qian Wan Port; | Name: | AOPACK BoxMaker; |

| Keywords: | Box making machine; | Application: | Corrugated carton making; |

| Box type: | Special standard carton; | Dimension(L*W*H): | 3410*1510*1860mm; |

| Brand Name: | AOPACK; |

AOPACK BM2508 is the most advanced and Integrated box making machine giving the solution to short run and serial production process of corrugated cardboard boxes.

Simple operation

You can choose from more than 20 common box types and hundreds of spare box types.All settings are entered directly from a user-friendly touch screen panel within one minute

Features

1. One person is enough for operating, saving labor

2. Only need 30 seconds to change the order, the minimum order quantity is 1, shorten the delivery cycle

3. High efficiency, without mold, saving your money

4. Automatic continuous paper feeding, makes the batch order is more convenient

5. Cardboard size up to 2500mm width with unlimited length, oversized cardboard boxes is available

6. Have the ability to making dozens of orders with different sizes and different box types every single day

Even more features

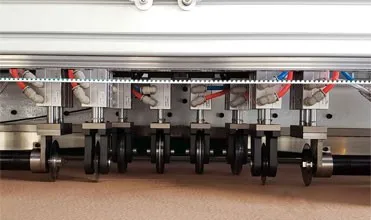

(1) 0.5-minute set-up

(2) 1 Horizontal cutting knive

(3) 2 Slotting knives

(4) 4 Cutting knives

(5) 4 Scoring/Creasing wheels

(6) Over 100 box styles

(7) Full servo drive motion

(8) Complete all settings for box production with an intuitive touch screen panel

(9) No additional tools or mold, servo drive to complete all settings

(10) Infeed, Slotting, Scoring, Slitting, Cutting, Trimming, Outfeed- in one compact machine

(11) Use of pneumatic motors, making the edges of the carton more beautiful and flat

BM2508

Main Features

1) Simple in structure, modular, easy to install and maintain.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) Running in a high automatization and intellectualization,no pollution

4) Infeed , slotting , scoring , cutting , trimming ,out feed ,in one compact machine

Cardboad Infeed

1. Can put 20-50 sheets of cardboard depending on the thickness of the board, automatic paper feeding

2. Continuous paper feeding system with suction negative pressure makes paper feeding more accurate

Horizontal Slot and Score

1. Two 500mm symmetrical slotting knives

2. Slotting knife and creasing beam integrated design

Vertical Score and Slit

4 Cutting knives

Two of the knives are rotated by the air motor to make the side of the carton more beautiful and flat

4 Scoring/Creasing wheels

Horizontal Cut and Cardboad Outfeed

Cut off excess cardboard without additional paper separator

The components of the equipment come from the

best manufacturers in the world as shown in the

following figure.

Recommendation: From paperboard selection to packaging, we recommend the most appropriate solution for you.

Installation on site: Engineer is responsible for installation and commissioning of field equipment to ensure normal operation of equipment.

Operational training: we are responsible for training related personnel in operation and maintenance

Quality Assurance: quality Assurance for one year, all expenses during the warranty period shall be borne by our company

Protective measures

Before the machine is packed in a wooden box, we will apply oil to the machine and wrap the protective film to avoid moisture and rust during the transportation of the machine and to ensure that the machine is in the best condition when it reaches the customer.

Packing

We will use the fumigation-free glued wood board to make the most suitable packaging for the product, preventing the machine from rusting and unnecessary collision during transportation.

Delivery

We package the products in the factory, and the logistics company transports the goods to the port and packs them on board.

-

Paper Egg Tray Making Machine for Small BusinessesMachine for Fabricating Paper Egg Trays for Small Businesses

-

Factory supply low price fully automatic napkin machine napkin making machine price

-

Small Manufacturing Machine Automatic Toilet Paper Rewinder Complete Equipment

-

6kw High Speed Fully Automatic Disposable Paper Cup Machine Price India Marketing Copper Motor GSM Power Engine Pump Technology

-

Paper cup machine automatic paper cup machine paper cup machine price

-

Henan Fuyuan low-cost new egg tray machine small enterprise egg tray production line machine making egg tray

-

Fully automatic machine for making disposable coffee cups

-

High Quality Paper Cup Production Making Machine Price,paper Cup Making Machine

-

Automatic V Fold Facial Tissue Hand Towel Paper Making Processing Machine Production Line

-

Small Pocket Envelope Making Machine for envelope

Other Products

-

$86000.00 / set

$86000.00 / set