Industrial Sawdust Sand Sludge Sea Salt Single Cylinder Rotary Dryer

-

Supplier: The Nile Machinery Co., Ltd. -

Region: Henan, China -

Contact: Ms Lily Li -

Price: $4814.00 / 1 - 1 sets

$4715.00 / >=2 sets -

Min. Order: 1 set

| Warranty: | 1 Year; | Power: | 3KW; |

| Color: | Customer's Request; | Certification: | ISO CE; |

| Installation slope(°): | 3-5; | Port: | Qingdao Port; |

| Max. intake temperature(℃): | 700-800; | Local Service Location: | Kenya; |

| Condition: | New; | Warranty of core components: | 1 Year; |

| Cylinder volume(m3): | 2.2; | Marketing Type: | New Product 2020; |

| Type: | Rotary Drying Equipment; | Place of Origin: | Henan China; |

| Payment Terms: | L/C,T/T,Industrial Sawdust/Sand/Sludge/Sea Salt Single Cylinder Rotary Dryer; | Core Components: | Motor; |

| Voltage: | 380V; | After-sales Service Provided: | Online support,Video technical support; |

| Brand Name: | The NIle CO.,LTD; | After Warranty Service: | Online support; |

| Factory visit: | Welcome; | Packaging Detail: | Standard container Electric gypsum fluorite slag chromite stones coal drum rotary dryer; |

| Key Selling Points: | High Productivity; | Dimension(L*W*H): | According to the model; |

| Weight: | 1.9t; | Capacity(t/h): | 0.3-0.5; |

| Machinery Test Report: | Provided; | Applicable Industries: | Manufacturing Plant,Machinery Repair Shops,Construction works ,Energy & Mining; |

| Package Preview: | ; | Supply Ability: | 500 Set/Sets per Month; |

| Showroom Location: | Kenya; | Video outgoing-inspection: | Provided; |

| Application: | mining ore process; |

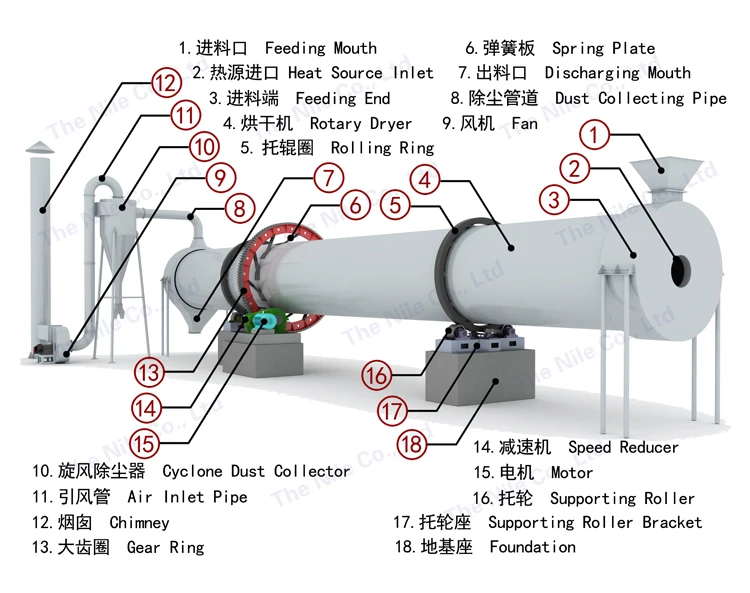

Single cylinder Rotary dryer is widely used for drying slag limestone,coal powder,slag,clay,etc.The dryer can also be used in building materials,metallurgy,chemical, and cement industry.Rotary Dryer mainly consists of dryer body,raw material feeding plate,driving and supporting device,seal ring,etc.Dryer can be generally divided into four types,they are rotary dryer,triple-drum dryer,indirect heat transfer dryer,vertical dryer.Different kind of dryer has its own characters and advantages,the specific choice of a special dryer depends on different.

Working principle

1.Materials are sent to the hopper of rotary dryer by belt conveyor or bucket elevator;

2.Materials enter the barrel installed with slope to horizontal line from the higher side,and hot air enters the barrel from the lower side,and the materials and hot air mix together;

3.Materials go to the lower side by gravity when the barrel is rotating;

4.Lifters on the inner side of barrel lift materials up and down in order to make materials and hot air mix completely,which is designed to improve the producing efficiency of rotary dryer.

Rotary Dryer Features

1.Our dryer adopts new Spreading plate device,which has guidance,flow,material functions;

2.It can make the material contained in the dryer radial cross-section to full uniform,the material will become thin and all;

3.The state of the heat flow entirely,to achieve the purpose of making full use of the heat;

4.Our dryer chooses reasonable operating parameters,coal consumption and power consumption of general baked dry machine more than 10-15%,one machine yields above 10-15%;

5.It has been widely used in the cement and mineral processing enterprise.

|

Specification |

Cylinder volume |

Capacity

(t/h) |

Installation slope

(°) |

Max. intake temperature

(℃) |

Motor power

(kw) |

weight

(t) |

|

∅0.6×8 |

2.2 | 0.3-0.5 | 3-5 | 700-800 | 3 | 1.9 |

|

∅1.0×10 |

7.85 |

1.2-2.0 | 5.5 | 6 | ||

|

∅1.2×10 |

11.3 | 2.4-3.0 | 7.5 | 11 | ||

|

∅1.5×12 |

21.2 | 4.5-5.7 | 15 | 18.5 | ||

| ∅1.5×15 | 26.5 | 5.7-7.1 | 15 | 20.5 | ||

| ∅1.8×12 | 30.5 | 6.5-8.1 | 18.5 | 21.3 | ||

| ∅1.8×14 | 35.6 | 7.6-9.5 | 18.5 | 23 | ||

| ∅2.2×12 | 45.6 | 9.7-12.2 | 22 | 33.5 | ||

| ∅2.2×16 | 60.8 | 13.0-16.2 | 22 | 38 |

A standard package in wooden boxes or containers.

The Nile Co.,Ltd.is committed to designing,producing grinding mills,crushers,conveyors,feeding machines,drying and calcinating as well as beneficiation equipment,fine sand recycling equipment etc,which are widely applied in electricity,metallurgy,mine and quarry, wharf,granary,chemical industry.Our products have been spread all over China,and also exported to European,American,Asian,African countries and enjoyed great popularity among our customers.

Our company owns an experienced and skilled sales and service team which compose a perfect service network.We will send the professional engineers to the installation sites and provide guidance for the installation,commissioning and initial run as well as planning administration of the equipments after purchase.

We can not only provide good quality sand making machine, but also provide the best service for our clients. The series of professional technology services will make you have an excellent product experience.

Pre-sale services:

(1) The advice of model choice.

(2) Design and manufacture machines according to customer's special requirements

(3) The company is free of charge to the user on-site engineering and technical personnel planning site for the user to design the best processes and program

After-sale services :

(1) Arrange technicians to go to the site to guide installation

(2) If your machine is out of warranty period, you can go to the Nile's overseas office to buy spare parts.

(4) complete sets of equipment installed, 1-2 full-time technical staff to stay free of charge to help customers on-site production of 1 month, until the user' satisfaction.

Q1: Are you factory or trade company?

A1: We are factory.

Q2: Where your products have been exported before?

A2: Our products have been sold to South Asia, Africa, South America, middle East and so on.

Q3: How will you help the customer to install the equipment?

A3: Our senior engineer will guide the installation and commissioning as well as the initial production at

Q4: How about the wear parts supply?

A4: We offer wear parts to our customer with our most favorable price. If there are problems youcould not handle, we will send our technicians to your place and you are therefore, responsible for all thecost involved.

Q5: What about the payment method?

A5:T/T, L/C Paypal is available

Q6: What about after-sale service?

A6:12 months warranty for all kinds of products.

-

Best quality 10kg 15kg freeze dryer food drying freeze dryer price household oil-free vacuum pump usa ready stock

-

Vacuum freeze dryer price

-

Household 6kg 8kg fruit food mini vacuum drying household freeze dryer freeze dryer with vacuum pump machine US spot

-

Mini Vacuum Freeze Dryer For Sale

-

Digital Display Multifunctional Combination 8 in 1 Heat Press Machine Sublimation Printing T-shirt Cup Tray Hat Printing

-

Vacuum drying machine, milk powder for vacuum drying

-

Factory price mini industrial vacuum food freeze dryer price

-

220V / 110V Household Professional Food Dehydrator Fruit Dryer

-

Stainless Steel Vacuum Chamber Vacuum Degassing Chamber Glass Cover Silicone for Evacuating and Protecting Food

-

2019 China Laboratory Industrial Small Freeze Dryer Price For Sale

Other Products

-

$5500.00 - $6000.00 / unit

$5500.00 - $6000.00 / unit -

$4000.00 - $4500.00 / unit

$4000.00 - $4500.00 / unit -

$2800.00 - $3500.00 / unit

$2800.00 - $3500.00 / unit -

$80.00 / unit

$80.00 / unit -

$999.00 / set

$999.00 / set -

$4000.00 - $5700.00 / set

$4000.00 - $5700.00 / set -

$100000.00 / set

$100000.00 / set -

$3000.00 / set

$3000.00 / set -

$4000.00 - $4500.00 / set

$4000.00 - $4500.00 / set -

$1000.00 / set

$1000.00 / set