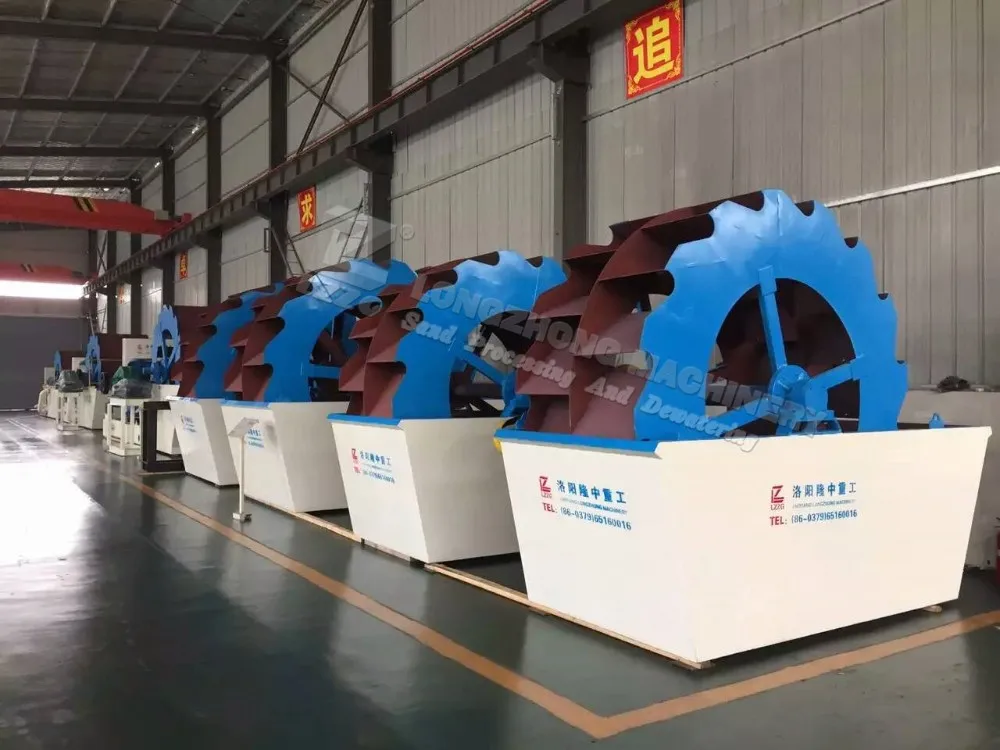

Hot selling large capacity coal washing plant manufacturers

-

Supplier: Luoyang Longzhong Heavy Machinery Co., Ltd. -

Region: Henan, China -

Contact: Ms Lynette Pang -

Price: $5000.00 /piece -

Min. Order: 1 piece

| Packaging Detail: | Standard packing; | Cyclone Size: | 350mm*2; |

| Material: | ≤10mm; | Screen Size: | 1800*4500mm; |

| Motor Type: | AC Motor; | Supply Ability: | 5 Sets per Week; |

| Weight: | 16.8; | Name: | Washing Machines Manufacturers; |

| Application: | Quarry/Mining/Construction, etc; | Place of Origin: | Henan, China; |

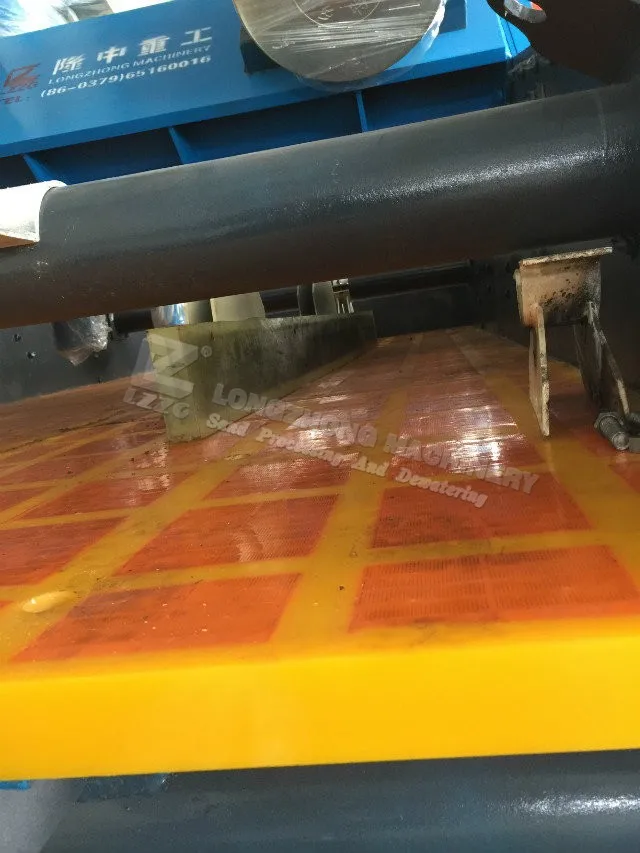

| Condition: | New; | Screen Material: | Polyurethane Screen; |

| Capacity(t/h): | 120-150; | Color: | Customized; |

| After-sales Service Provided: | Video technical support,Online support,Overseas service center available; | Spare Parts Supply: | Yes; |

| Usage: | Washing, Dewatering ,Recycling; | Payment Terms: | L/C,T/T,Western Union; |

| Port: | Shanghai, Qingdao; | Brand Name: | LZZG; |

| Warranty: | 1 Year; | Dimension(L*W*H): | 9800*2400*3670; |

| Certification: | ISO; |

Product Application

Gold wash plant is based on sand washer and sand recycling system main tech, we make it a compact multiple function sand washer. It is widely used for crushed sand, river sand, lake sand or sea sand washing, screening, recycling and dewatering.

Working principle

Step 1: Washing

The electric motor runs slowly with the impellor after decelerated by the belt, decelerator and gears wheel. The sand and stone flow into washing launder from feeding launder, rolls with the impellor, and grinds each other. The impurity covering the sand is washing away. At the same time, add more water, the strong water flow will take away waste and some low-weight wastes from washing launder. Through the above process, the washing function is finished. The clean sand and stone is lift up by vane. When it goes up slowly, the water begins to drop through the mesh and fall back in the washing launder.

Step2: dewatering--

Qualified sand is shoveled to the dewatering screen directly. This dewatering screen sieve is made of PU polyurethane material, no blocking, can bear high temperature and corrosion resistance is high, service longer working hours. From this step, wet sand moisture can be highly reduced.

Step3: recycling--

Waste sand water is extracted by slurry pump into high pressure sediment separator, fine sand 0.16-3mm is sprayed onto polyurethane screen also for de-watering, the waste water is back to return box and flowing out.

| Technical Parameters | ||||||

| Feeding Size(mm) | Production (t/h) | Water (m³/h) | Overall Dimension (L*W*H)(mm) | |||

| LZ26-35 | 28.4 | 350 | ≤10 | 20-50 | 50-80 | 6200*2150*2670 |

| LZ26-55 | 31.9 | 250*2 | ≤10 | 30-60 | 60-130 | 6200*2150*2670 |

| 300*2 | ≤10 | 50-120 | 70-150 | 7200*2900*3070 | ||

| LZ36-75 | 350*2 | ≤10 | 120-150 | 150-300 | 9800*2400*3670 | |

Main Features

1. Recycling 0.16-0.3mm fine sand;

2. High productivity and 95% fine particles in the material can be recycled;

3. Solving cleaning problem of sedimentation tank and improving economic performance at the same time.

Machine Parts

Name: Polyurathane Screen

Brand: LZZG

Original: China

Machine Parts

Name: Cyclone

Brand: LZZG

Original: China

Machine Parts

Name: Gear Wheel

Brand: LZZG

Original: China

Machine Parts

Name: Motor

Brand: LZZG

Original: China

Machine Parts

| Model | |

| Weight | |

Vibrating screen: YA series,1 layer, 2 layers, 3 layers,4layers...

Sand washing machine: XSD wheel bucket sand washer,LSX spiral sand washer

Dewatering screen: TS series,the final water content down to 12-15%

Sand recycling system: 0.16-3mm fines recycling machine, LZ sand washing and recycling machine

Certificate Honors

› Pre-sale Service:

Choice of model

Designing and manufacturing product according to customer's special requirement

Company will arrange engineer to customer's site,designing site and discussing project

› Content on service:

Product inspection

Help customer to formulate the construction plan

› After-sale Service:

Assign special after sale service team to site guiding customer to install and adjust machines

Training operator on site

Yes,once you place the order,the delivery will be done within one week.

2.Can the machine parts be replaced?

Yes,You can get them directly from us in a low price, and we make sure the easy maintainence and replacement .

3.How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every product before delivery.Please check our working site. If our quality is not good, i don't think we can sell so well.

4.Guaranteed?

Yes. If products'quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

5.How about price?

Yes, we are factory and be able to give you the lowest price than market one, and we have a policy that " for saving time and absolutely honest business attitude,we quote as low as possible for any customer, and discount can be given according to quantity".

Now, please click the following contact to send us email !

↓↓↓

-

Large-capacity double-screw sand washing machine double-screw sand washing machine

-

2022 mobile sand washing machine sand washing machine price aggregate stone sand washing machine

-

River sand silica gel sand washing machine spiral sand cleaning machine price

-

100 Tph Sand Washer Fine Material Washer Screw New 2 Years Warranty

-

LDHB 2LD36-100-2442J double-wheel wet silica sand washing and dehydration equipment

-

Shaking Table Fine Gold Recovery Equipment Genemi Mineral Separator

-

dry washer Gold mining dry washer

-

Large capacity professional new sand washing machine

-

Small capacity 10tph 20tph 25tph log washing machine, double helix log washing machine for sale

-

Drum washing machine price sand washing factory for sale ore washing machine

Other Products

-

$5000.00 / piece

$5000.00 / piece