Drum washing machine price sand washing factory for sale ore washing machine

-

Supplier: Henan Fangda Industrial Corporation Ltd. -

Region: Henan, China -

Price: $62840.00 /set -

Min. Order: 1 set

| place of origin; place of origin: | Henan, China (Mainland) | Dimensions (L*W*H): | different |

| After-sales service provides: | Video technical support | Warranty: | 1 year |

| Marketing Type: | normal product | Video external inspection: | if |

| Applicable industries: | Manufacturing, Construction, Energy & Mining | weight: | Kilogram |

| Packaging Details: | 1. Standard container 2. Bare package 3. Wooden case | Local service location: | not any |

| port: | Qingdao, Shanghai, Tianjin | brand: | F&D Industries |

| Health status: | new | Certification: | International Organization for Standardization |

| Core components: | PLC, engine, bearing, motor, gear, pump | payment terms: | Letter of credit, wire transfer, wire transfer, etc. |

| Motor Type: | AC motor | Showroom location: | not any |

| Mechanical test report: | Not available | Core Components Warranty: | 1 year |

| Supply capacity: | 100 sets per month | Packaging Preview: | |

| Capacity (tons/hour): | 150-250 |

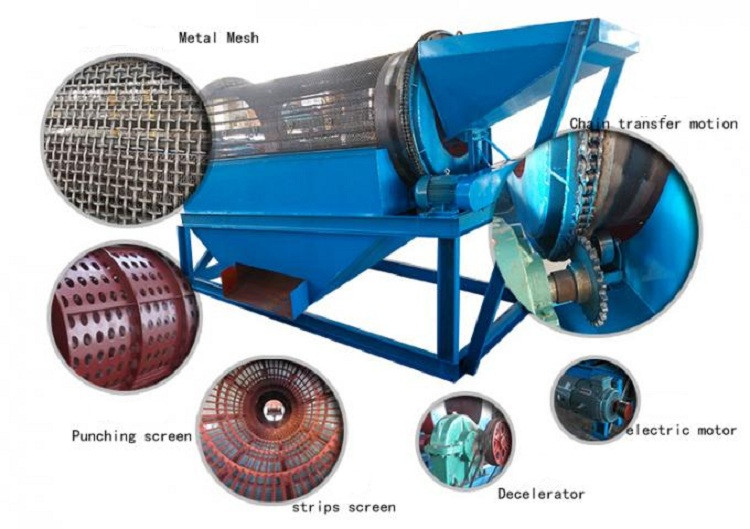

Front-loading washing machines are suitable for ore separation in ferrous and non-ferrous metal mining. It washes raw ore with water to remove clay, sand and other impurities. This washing process can make the raw ore meet the requirements of beneficiation and economy. It is widely used to remove coarse concentrates of clay, especially granular ores buried in mud. It is an ideal equipment for large-capacity and high-demand ore and stone washing industries.

The stone washing machine uses mechanical equipment to clean the rough stone. The quality requirements of the project and sufficient productivity are guaranteed to meet the supply of stone materials for the concrete batching plant.

Its work flow is generally: raw material storage, transportation, cleaning, finished product transportation, sewage sedimentation and reuse.

Raw materials are generally stored in hoppers. Hopper capacity depends on loading height, transport height and flow angle of raw material. The larger the hopper capacity, the better.

The raw material is usually conveyed by belt. According to the sludge content of the raw material, it is best to set a throttling device at the mouth of the bucket to control the amount of cleaning.

Since the amount of mud and dust attached to the rough stone provided by the quarry is not large and the adhesion is small, the cleaning process does not need to be too long. The key is that when the stone is cleaned and discharged, the visceral water in the tank cannot be attached to the visceral water in the tank, resulting in secondary pollution of the stone.

Finished stone is usually transported by belt conveyor to finished product storage area or hopper for use, so it is best to cover or rinse the storage area.

Regardless of the type of stone washing machine, a large amount of sewage is generated, and the water consumption is almost the same. Considering the environmental requirements, sewage sedimentation and reuse tanks are generally set up. The volume and settling level of the pond are determined according to the output, and also consider the mechanical or manual cleaning of the sludge.

Large-capacity hopper, easy to disassemble and assemble, the screw blade stirs, rolls, pushes the material, and cleans the stone for the second time. The principle is the same as that of the drum mixer. Easy disassembly and assembly, simple requirements for site and foundation. Suitable for mobile construction occasions.

|

Model |

Feed size (mm) |

Mixing barrel length (mm) |

Screen drum length (mm) |

Screen diameter (mm) |

Motor power (kw) |

Speed (r/min) |

Capacity (tons/hour) |

|

Φ1.5*6m |

250 |

4000 |

2000 |

5-20 |

11 |

12.5 |

30-60 |

|

Φ1.8*9m |

300 |

6000 |

3000 |

15 |

10.3 |

50-100 |

|

|

Φ2.0*11m |

350 |

8000 |

3000 |

18.5 |

9.2 |

80-150 |

|

|

Φ2.2*13m |

400 |

10000 |

3000 |

30 |

8.5 |

100-200 |

|

|

Φ2.5*15m |

400 |

10000 |

5000 |

37 |

7.8 |

150-250 |

Note: The above technical parameters are for reference only.

Our company can customize products according to the actual situation of users.

-

Large-capacity double-screw sand washing machine double-screw sand washing machine

-

2022 mobile sand washing machine sand washing machine price aggregate stone sand washing machine

-

River sand silica gel sand washing machine spiral sand cleaning machine price

-

100 Tph Sand Washer Fine Material Washer Screw New 2 Years Warranty

-

LDHB 2LD36-100-2442J double-wheel wet silica sand washing and dehydration equipment

-

Shaking Table Fine Gold Recovery Equipment Genemi Mineral Separator

-

dry washer Gold mining dry washer

-

Large capacity professional new sand washing machine

-

Small capacity 10tph 20tph 25tph log washing machine, double helix log washing machine for sale

-

Fine sand collection equipment sand recovery machine with wheeled sand washing machine

Other Products

-

$10000.00 / set

$10000.00 / set -

$3000.00 / set

$3000.00 / set -

$55030.00 / set

$55030.00 / set -

$1400.00 / set

$1400.00 / set -

$6430.00 / set

$6430.00 / set -

$7000.00 / set

$7000.00 / set -

$185630.00 / set

$185630.00 / set