MHB1562 automatic finger joint machine wire wood machine

-

Supplier: Qingdao Weichang Industry And Trade Co., Ltd. -

Region: Shandong, China -

Contact: Mr Mike Lee -

Price: $12500.00 / 1 - 4 sets

$11700.00 / >=5 sets -

Min. Order: 1 set

| Core components: | motor | Core Components Warranty: | 1 year |

| Saw blade spindle power: | 4.0kW | Maximum engagement force: | 7.8 tons |

| brand: | Jinchuang | place of origin; place of origin: | Shandong China |

| Maximum assembly length: | 6200mm | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| air pressure: | 7.8 tons | Maximum Assembly Thickness: | 80mm |

| Warranty: | 1 year | Weight (kg): | 7800kg |

| Video external inspection: | if | Marketing Type: | normal product |

| Mechanical test report: | if | weight: | 2500kg |

| port: | Qingdao Shanghai as you wish | Health status: | new |

| Showroom location: | Vietnam, Indonesia | Main selling point: | high productivity |

| Applicable industries: | Hotels, clothing stores, building materials stores, machinery repair shops, manufacturing plants | Dimensions (L*W*H): | 8500*1700*1500mm |

| Feed conveyor power: | 0.75kw | Feed rate: | 30-60m/min |

| Saw blade spindle speed: | 3700 rpm | Voltage: | 220V 380V |

| Supply capacity: | 50 sets per month | Maximum Assembly Width: | 150mm |

| Oil pump motor power: | 2.2kW | Packaging Details: | Wooden box stretch film or as your request |

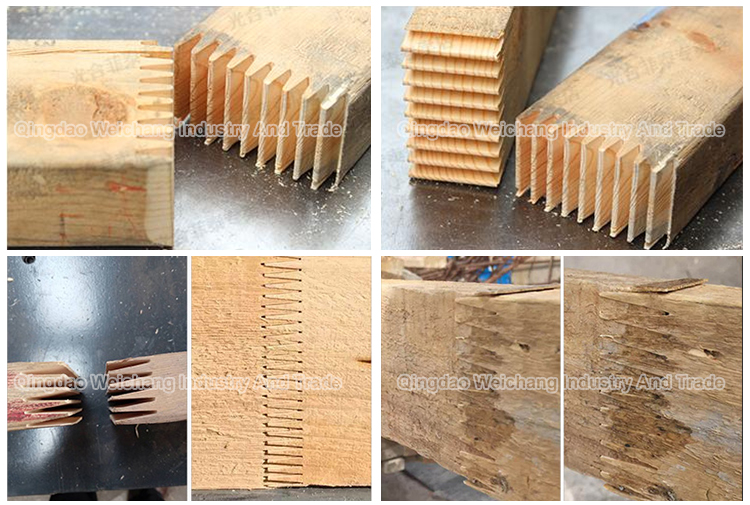

application:

MHB1525.MHB1530.MHB1546.MHB1562 automatic finger joint assembly machine is mainly used for longitudinal lengthening of wood, which is the magic weapon of fingerboard.

feature:

1. Processing speed: 700 pieces/hour (skilled worker);

2. Imported PLC microcomputer control, simple operation, only one employee per unit;

3. The seam length can be adjusted arbitrarily.

4. Sufficient power, fast feed and long service life

Advantage:

1. Improve the utilization rate of wood and reduce waste of resources

2. The reuse of wood greatly reduces the cost of the enterprise

3. Compared with most machines on the market, it is more convenient and simpler. One person can use it, greatly saving manpower

4. Refers to the sheet formed after splicing, the subsequent processing deformation is small, and the performance is better than the ordinary sheet.

5. The second push part of the finger joint assembly machine adopts the design of long + short double push plates. This structure can assemble very short workpieces and reduce costs.

Tontechnical parameter:

| Maximum assembly length | 6200mm | |||

| maximum assembly width | 150mm | |||

| Maximum Assembly Thickness | 80mm | |||

| maximum engagement force | 7.8 tons | |||

| Saw blade spindle power | 4.0kW | |||

| Oil pump motor power | 2.2kW | |||

| Saw blade spindle speed | 3700 rpm | |||

| Feed rate | 30-60m/min | |||

| Feed conveyor power | 0.75kw | |||

| Pinch wheel feeder power | 0.75kwx2 | |||

| Dimensions (LxWxH) | 8500*1700*1500mm | |||

| weight | 2500kg | |||

-

Fully automatic finger joint machine production line plank woodworking machinery

-

Easy-to-operate woodworking finger joint woodworking equipment production line

-

Comb carpentry woodworking semi-automatic finger joint tenon machine

-

590mm Semi-Automatic Woodworking Finger Forming Machine

-

Fully automatic finger joint production line machine

-

Shepa woodworking automatic finger joint forming line, SHMB3515E

-

Industrial woodworking plank finger-joint spindle former tenon jointer seam cutting knife saw tool machine

-

Wood finger-jointed board whole wood core veneer furniture table factory 1220x2440x18mm coated birch E1 poplar natural veneer CN;SHN

-

SAMACH high-efficiency finger joint automatic finger joint production line

-

MX3515 wood finger jointing machine

Other Products

-

$50100.00 - $55110.00 / set

$50100.00 - $55110.00 / set -

$5000.00 / set

$5000.00 / set -

$8000.00 / set

$8000.00 / set