closed cell polyurethane insulation foam insulation machine sprayer pu foam sprayer

-

Supplier: Shandong Hightop Group -

Region: Shandong, China -

Contact: Ms Kerry Chen -

Price: $3100.00 / 1 - 9 sets

$2900.00 / 10 - 999 sets

$1000.00 / >=1000 sets -

Min. Order: 1 set

| Voltage: | 110V/220V/380V | output: | 2-12 kg/min |

| Warranty: | 3 years | application: | PU Foam Polyurethane Spray and Injection |

| brand: | China Nonferrous Metals Group | Product Category: | Foam sprayer |

| port: | Qingdao, Ningbo, Shanghai | Applicable industries: | Hotels, Building Materials Stores, Manufacturing Plants, Mechanical Repair Shops, Farms, Home Use, Retail, Construction, Energy and Mining |

| Maximum output pressure: | 11Mpa | Energy source: | 220V/110V/380V 50/60HZ |

| Core Components Warranty: | 3 years | Maximum Hose Support: | 90m |

| Supply capacity: | 500 pieces per month | place of origin; place of origin: | Shandong China |

| Drive mode: | pneumatic | Showroom location: | Spain, Romania |

| Core components: | Pumps, PLCs, Pressure Vessels | Mechanical test report: | if |

| Health status: | new | Power (kW): | 7.5 |

| payment terms: | L/C,Western Union,T/T | Packaging Preview: | |

| Video external inspection: | if | Raw output: | 2-12 kg/min |

| strength: | 7.5KW | product name: | Closed cell polyurethane insulation foam insulation machine spraying equipment |

| Processing type: | Foaming machine | Packaging Details: | Wooden box closed cell polyurethane insulation foam insulation machine spraying machine pu foam spraying machine |

| Type of machine: | pneumatic | Main selling point: | easy to operate |

| Marketing Type: | New Products 2020 | Weight (kg): | 250kg |

| Minimum order quantity: | 1 set |

closed cell polyurethane insulation foam insulation machine sprayer pu foam sprayer

Introduction of closed cell polyurethane insulation foam insulation machine spraying machine pu foam spraying machine

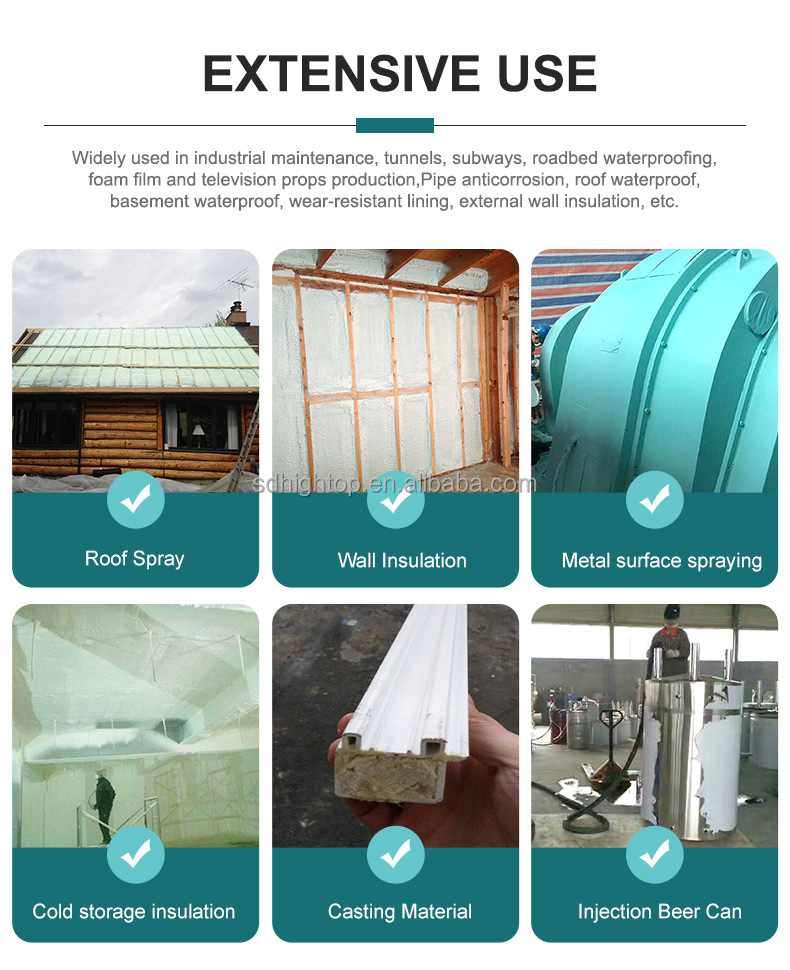

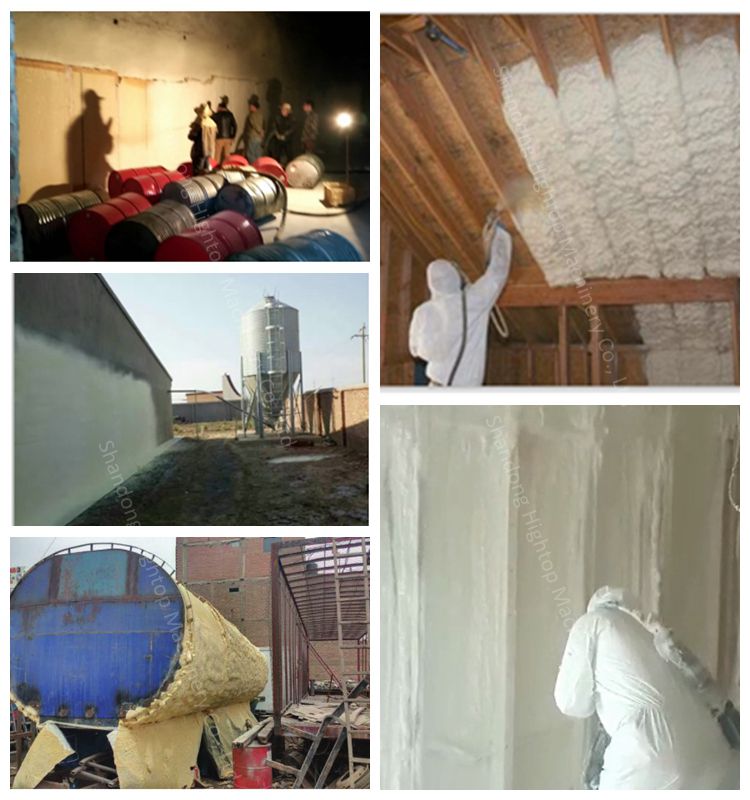

closed cell polyurethane insulation foam insulation machine sprayer pu foam sprayerIt can be used in various construction environments, spraying two-component materials such as polyurethane foam material (optional), widely used in embankment waterproofing, pipeline anticorrosion, auxiliary cofferdam, storage tank, pipeline coating, cement layer protection, sewage treatment, Roofing, basement waterproofing, industrial maintenance, wear-resistant lining, cold storage insulation, wall insulation, etc.

Here's why we recommend it:

1. In the cold winter, the machine can quickly preheat the foaming chemicals to help save time and improve the spraying effect and foaming effect. Equipped with a return valve, it is very convenient for operators to recycle chemicals.

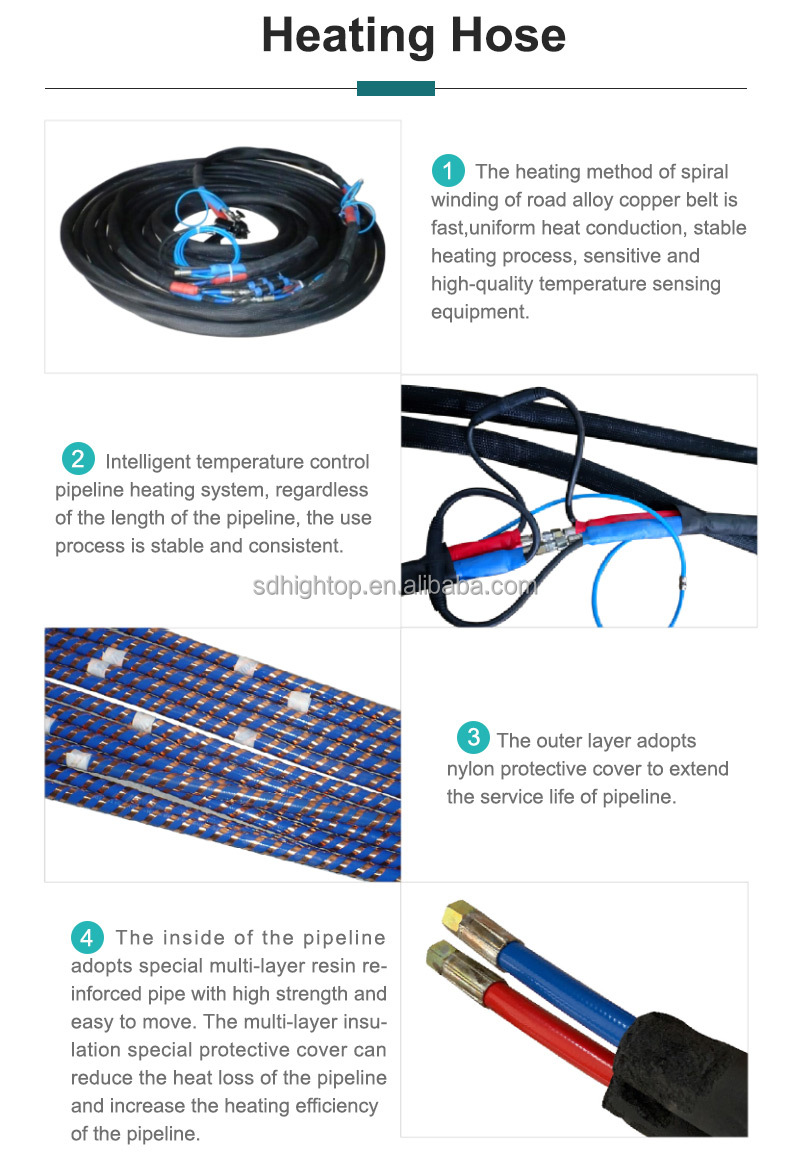

2. The heating hose is the same as the Graco machine, with internal heating and low-voltage current to protect the operator's personal safety to the greatest extent.

3. Display in Fahrenheit and Celsius, which is convenient for users in different regions to view their habits.

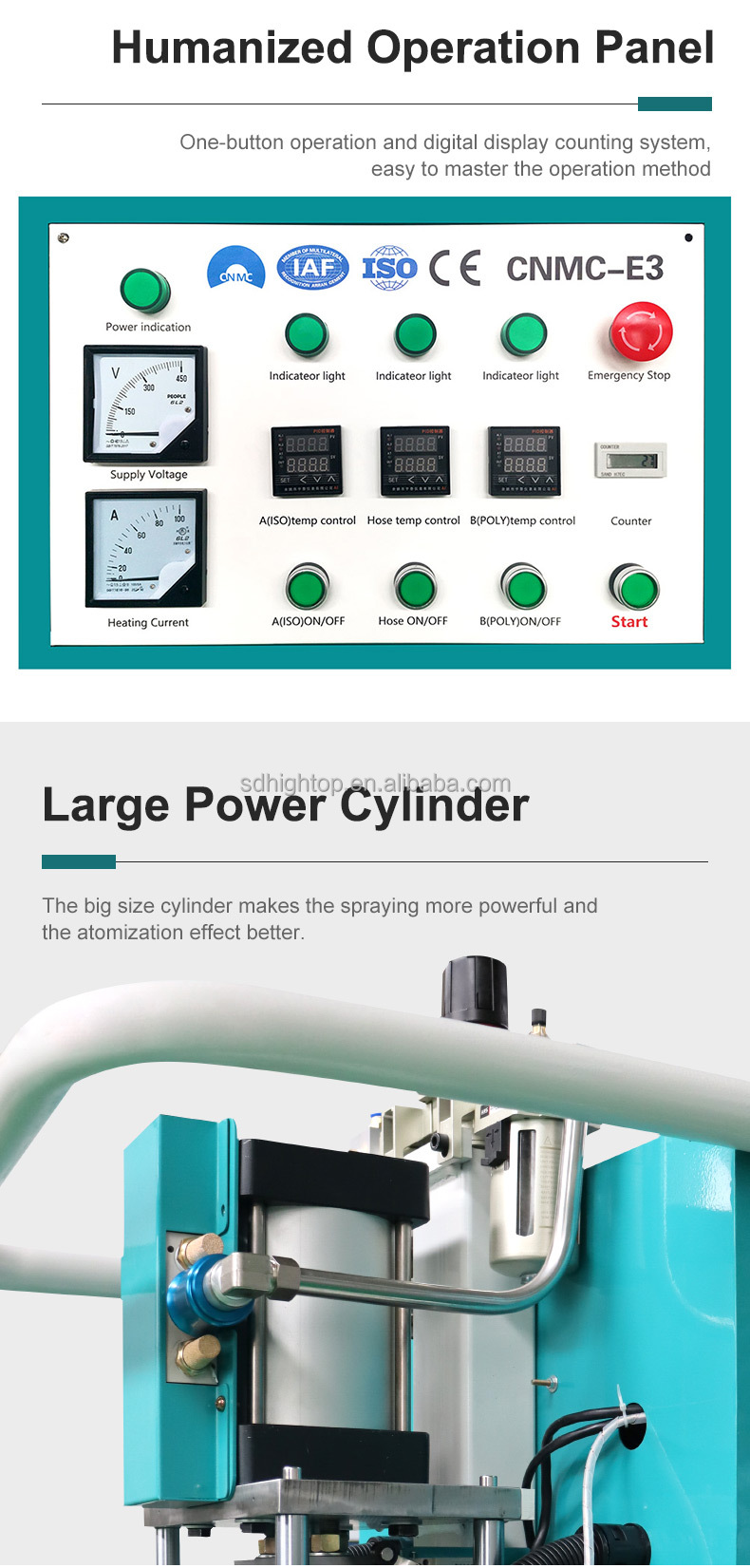

Plastic spray insulation machine CNMC-E3feature:

1. UseHigh power cylinderMake the spray stronger and the atomization effect better.

2. The heating hose of the new upgraded machine CNMC-E3 heats up faster.In the cold winter, the machine can be warmed up

Quick lather helps save time and improves spray and lather results. Equipped with return device

valve, which is very convenient for the operator to recycle chemicals.

3. The machine containsleakage protectorPrevent machine leakage and human body electric shock,

Improve the safety performance of the machine.

4.Add voltmeter and ammeter, so the voltage and current conditions inside the machine can be detected.

5. The appearance design conforms to the principle of artificial mechanics, and it is easier to move the machine.

6.Heated hose with internal heating and low voltage current, to protect the operator's personal safety

to the greatest extent possible.

7. The quick door is installed, which makes the maintenance and inspection of the machine more convenient

Plastic spray insulation machineCNMC-E3 Details:

Parameters of closed cell polyurethane insulation foam insulation machine sprayer pu foam sprayer

|

Model |

CNMC-E2 & CNMC-E3 |

|

energy source |

110V/220V/380V |

|

heating power |

7.5KW |

|

drive mode |

pneumatic |

|

raw output |

2~12kg/min |

|

maximum working pressure |

17Mpa |

|

AB material yield ratio |

1:1 |

|

Maximum hose support |

90m |

|

Complete set list: |

|

|

host |

1 set |

|

spray gun |

1 set |

|

heated hose |

15m |

|

Pump |

2 |

|

spare parts |

1 set |

|

User's Manual CD-ROM |

1 serving |

Closed cell polyurethane thermal insulation foam insulation machine spraying machinepu foam spraying machineclosed cell polyurethane thermal insulation machine spraying machinepu foam spraying machine

advantage:

1. Primary heating system:

It consists of two separate independent block heaters without seals.

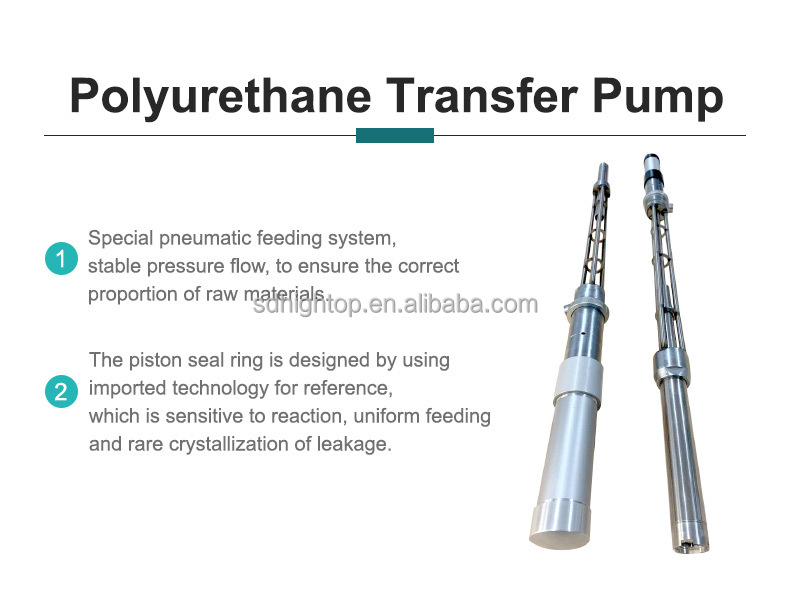

2. Proportional pump:

The system consists of two positive displacement piston pumps driven by air motors.

3.Recirculation system:

The recirculation of the two components allows for faster reaching of the preset temperature at the heater before starting to spray and during temporary shutdowns.

4. Hose heating system:

hoseThe heating system is designed at 1000W per 15m, allowing heating up to 90m.

Image of closed cell polyurethane thermal foam insulation machine spraying equipment pu foam spraying machine

Insulation foam spraying machine CNMC-E3:

Application of closed cell polyurethane insulation foam insulation machine spraying equipment pu foam spraying machine

Insulation Foam Spray:

Polyurethane foam injection molding:

-

High Pressure Polyurethane Foam Injection Machine Polyurea Spraying Machine

-

High Viscosity Pneumatic Oil Pump Grease Barrel Pump Air Barrel Pump

-

Outdoor party event hot sale snow foam daddy super re maquina de espuma foam machine

-

Q2600 Polyurethane Foam Sprayer

-

Portable Polyurethane Sprayer Foaming Machine

-

Automatic Control EPS Foam Vertical Cutting Machine

-

Closed cell polyurethane foam insulation machine FD-E10H

-

Closed cell polyurethane thermal foam insulation machine spraying machine pu foam spraying machine

-

Sponge cutter for kitchen cleaning

-

MDI Rigid Polyol Isocyanate Polyurethane Foam Insulation Spray From China Factory!

Other Products

-

$100.00 / set

$100.00 / set -

$198.00 - $399.00 / pair

$198.00 - $399.00 / pair -

$89.00 / set

$89.00 / set -

$4300.00 / set

$4300.00 / set -

$2000.00 / piece

$2000.00 / piece -

$3750.00 / set

$3750.00 / set -

$600.00 / set

$600.00 / set -

$1500.00 / set

$1500.00 / set -

$25.00 / set

$25.00 / set -

$600.00 / set

$600.00 / set