HDPE LDPE LLDPE ABA High Speed Blow Film Machine Plastic Extruder

-

Supplier: Wenzhou Ruixin Plastic Machinery Trading Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms Rita Yuan -

Price: $5000.00 /set -

Min. Order: 1 set

| Output (kg/hour): | 30 - 60 | energy consumption: | About 15-20KW/H |

| Supply capacity: | 30 sets per month | brand: | Ruixin |

| Material: | physical education | Plastic Processing: | HDPE, LDPE, LDPE, PLA |

| application: | Movie | Heating ring: | Cast aluminum heating coil |

| Packaging Preview: | payment terms: | Wire Transfer, Western Union, Cash | |

| Warranty: | 1 | Dimensions (L*W*H): | 3200*1700*3900 |

| Screw diameter (mm): | 50 | Certification: | CE, SGS, ISO, BV |

| Film Thickness (mm): | 0.001 - 0.12 | Rewinding method: | Friction winder |

| port: | Ningbo | Film width (mm): | 100 - 600 |

| Screw speed: | 10-120m/min | Applicable industries: | Energy & Mining, Mechanical Repair Shops, Manufacturing Plants, Food Stores, Clothing Stores, Food & Beverage Stores, Construction Works, Farms, Printing Stores, Home Use |

| color: | blue and white | Die head material: | 40Cr |

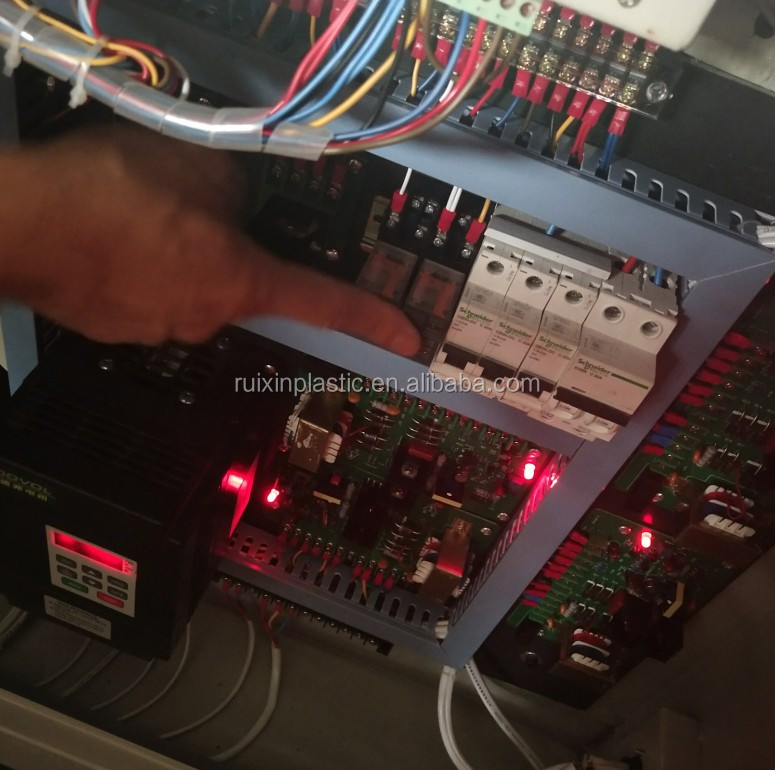

| Electrical components: | Chint China Best Brand | Packaging Details: | Wrap it in wood/plastic wrap |

| model: | RSJ | After-sales service provided: | Free spare parts, online support, on-site installation and commissioning training, on-site maintenance and repair services, video technical support |

| Main selling point: | energy saving | Name type: | Film blowing machine plastic extruder |

| place of origin; place of origin: | Zhejiang, China | Voltage: | 380V/220V/415V |

| motor: | China Siemens brand | year: | 20190921 |

| Health status: | new | Layers: | single layer |

High Speed HDPE LDPE LLDPE ABA Blown Film Machine Plastic Extruder :

1. TheFilm blowing machine plastic extruderSuitable for blowing low density polyethylene (LDPE) high density polyethylene (HDPE) linear low density polyethylene (LLDPE) and biodegradable corn starch, widely used in food, clothing, garbage bags, vest bags and other civil and industrial packaging .

2. The extruder barrel and screw are all made of high-quality alloy steel, compacted and precisely processed, with the best hardness and corrosion resistance. Specially designed screw, high output and good plasticization.

3. The winding power adopts torque motor, which can maintain proper tension, neatly winding, and easy to change the roll.

Model | RSJ-50-700 | RSJ-55-900 | RSJ-60-1100 | ||

Roller width(mm) | 700 | 900 | 1100 | ||

Maximum paving width (mm) | 600 | 800 | 1000 | ||

Thickness(mm) | 0.008-0.12 | 0.008-0.12 | 0.008-0.12 | ||

Maximum output (kg/h) | 30-40 | 40-50 | 50-70 | ||

raw materials | HDPE LDPE LLDPE MLLDPE / Biodegradable Materials | ||||

Screw diameter | 50mm | 55mm | 60mm | ||

Screw material | SACM-645 /38CrMoAlA Nitriding polishing | ||||

Screw L/D | 30:1 | 30:1 | 30:1 | ||

Main power (kw) | 11 | 15 | 18.5 | ||

Blower (Kw) | 1.5 | 1.5 | 2.2 | ||

Compressor (kW) | 1.5 | 1.5 | 2.2 | ||

takeoff speed | 10-80m/min | 10-80m/min | 10-80m/min | ||

Take-off motor(Kw) | 1.5 | 1.5 | 2.2 | ||

Total power (kw) | ≈15 | ≈18 | ≈22 | ||

Dimensions (L×W×H) M | 3.2×2.5×3.9 | 4.2×3×4.2 | 4.8×3.8×5 | ||

Weight (T) | ≈1.5 | ≈2 | ≈3.5 | ||

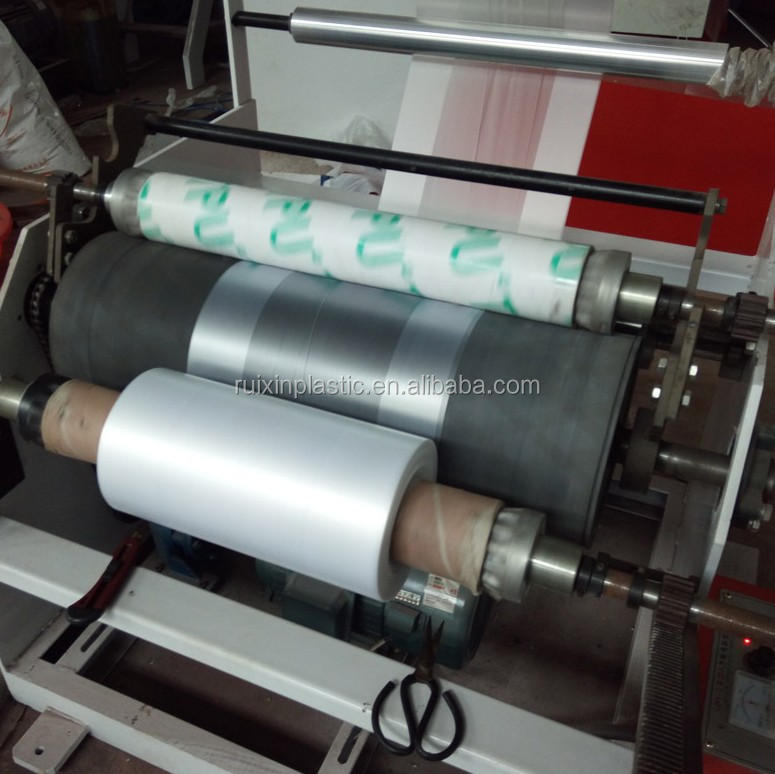

detailedpicture

The internal runner and external hard chrome plating of the mold increase the wear resistance and corrosion resistance of the mold, and then polished,

The winding adopts frequency conversion speed regulation to keep it stable, and the cylinder presses the roller to confirm the tightening to avoid injury to workers.

The winder adopts a torque motor to adjust the tension to keep the film flat and wrinkle-free

Our machines can use HDPE ,LDPE , LLDPE

Our T-Shirt Bag Roller

Degradable plastic bag, degradable plastic bag, degradable plastic roll film

→Professional since 2006

1) 1500 square meters warehouse

2) The monthly export volume exceeds 30 units,

3) The market is South America, Middle East

Africa, Asia

→ Siemens CNC machining parts

1) Precise machining, reject mistakes

2) Experienced professional team

3) The machine has a longer life and does not rust

→24 hours online service

1) On-time online service

2) Delivery in a short time

3) Free drawings and instructions

4) Professional export team

-

Small HDPE LDPE Blown Film Machine Garbage Bag Production Line For Sale

-

Product Show Pe, Ldpe, Hdpe, Plastic Blown Film Machine/Blown Film Machine Price

-

Single Layer Rotary Die Plastic Blown Film Machine Price

-

High Speed HDPE Ldpe Plastic Film Garbage Bag Dual Die Blown Film Extrusion Machine

-

single layer double layer water cooling pp film blowing machine pp film extruder

-

Mini film blowing machine (CE)

-

2018 New Factory Direct Selling Low Price Fully Automatic Plastic PE Mini Film Blowing Machine

-

Mini economical HDPE LDPE PBAT PLA plastic film blowing machine

-

High-speed film blowing machine

Other Products

-

$5000.00 / set

$5000.00 / set -

$4000.00 / set

$4000.00 / set -

$1350.00 / set

$1350.00 / set -

$3000.00 / set

$3000.00 / set -

$4000.00 / set

$4000.00 / set -

$5000.00 / set

$5000.00 / set