Hot selling PE high speed t-shirt bag flexographic film printing machine

-

Supplier: Wenzhou Ruixin Plastic Machinery Trading Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms Rita Yuan -

Price: $3000.00 /set -

Min. Order: 1 set

| application: | plastic film, roll paper, | Health status: | new |

| Material: | Pe Opp Bopp Paper | Dimensions (L*W*H): | 2300x1600x2200 |

| brand: | Ruixin | weight: | 1200kg |

| Plate type: | flexo press | Applicable industries: | Printing and packaging |

| Key words: | flexo printing press | Supply capacity: | 30 sets per month |

| usage: | Paper Printers, Label Printers, Card Printers, Film Printers | Plate thickness: | 2.28mm |

| Doctor Blade: | optional | Packaging Details: | Packed in wooden box or plastic wrap |

| Warranty: | 1 year | type: | flexo printing press |

| color: | red/white/blue | Printing Type: | flexo press |

| port: | Ningbo, Shanghai | After-sales service provided: | Online support, free spare parts, on-site installation and commissioning training, on-site maintenance and repair services, video technical support |

| nervous: | Magnetic powder crusher | place of origin; place of origin: | Zhejiang, China |

| Anilox roller: | metal roller | payment terms: | L/C,T/T,Western Union,Cash |

| Voltage: | 380V/220V/415V | Auto grade: | automatic |

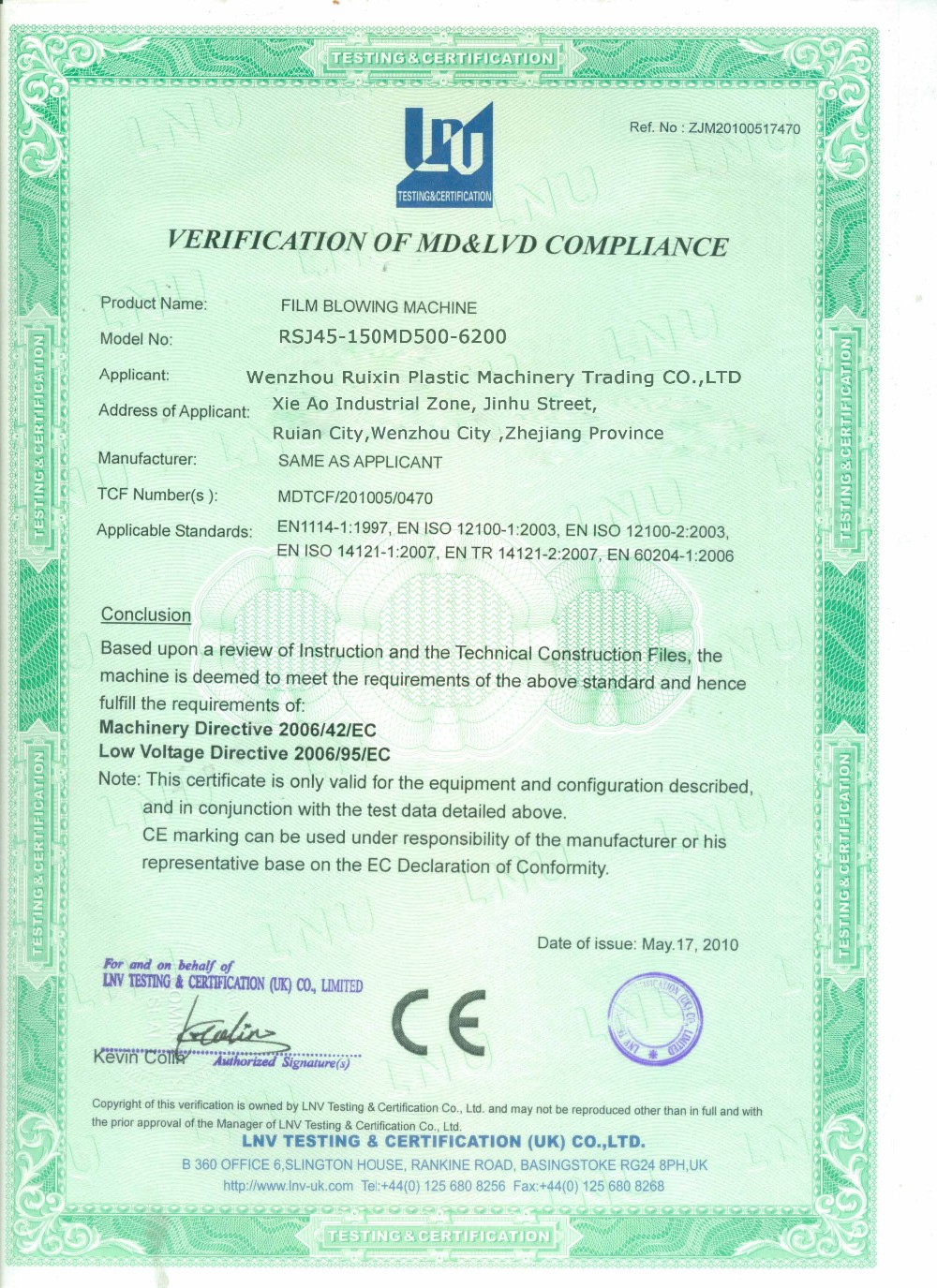

| Certification: | CE, ISO, SGS | Colors and Pages: | Polychromatic |

| Name: | Flexo Film Press |

Hot selling PE high speed t-shirt bag flexographic film printing machine:

Flexographic film printing machine is used for printing polyethylene, polypropylene bags, cellophane, roll paper and other packaging materials. It is an ideal printing equipment package for the production of commodity paper packaging bags, supermarket handbags, vest bags, clothing, etc.

Performance and Features:

1. Easy to operate, flexible to start, accurate color registration.

2. The meter counter can set the number of prints as needed. Automatically stop when the quantity is reached or the material is cut off.

3. The printing drum moves up and down, and the ink is automatically stirred after the up and down.

4. The knurled roller transmits the ink, and the ink color is uniform.

5. The reliable drying system cooperates with high-speed rotation, and the circuit is automatically cut off when it stops.

6. 360° continuously adjustable longitudinal register device.

7. Frequency conversion speed regulation, adapt to different printing speeds.

8. There are jog/stop buttons on the plate roller seat and the reel stand, which are convenient for operating the machine during plate loading.

| 180mm-1200mm | |||

| 0-60m/min | |||

| ±0.2mm | |||

RSJ60-1100 Film Blowing Machine

MB-2700 Three-layer Co-extrusion Blown Film Machine

DFHQ-500x2 high speed vest bag making machine

Our US customers visited and checked the working and running process of the fully automatic vest bag making machine, they are new to this field and they only stayed here for 2 days to learn the operation of the machine!

YT-2-600 Flexographic printing machine

-

Flexographic Printing Machine Corrugated New High Speed Ci Woven Shopping Bag Flexographic Printing Machine

-

YT-4600 flexographic printing machine flexographic printing machine 6 colors

-

Flexo Label Printing Machine, High Quality Flexo Printing Machine, 8 Color Flexo Printing Machine

-

Online Monochrome Logo Flexo Printing Machine

-

2 Colors Non Woven Film Bag Flexo Printing Machine Plastic Paper Flexo Sachet Printing Machine Machinery

-

Fully automatic flexo printing machine printing machine

-

2 3 4 5 6-color paper cup blank fan-shaped printing punching machine

-

Digital label printing machine ZBRY-480

-

With Dryer Logo Flexographic Printing Machine Automatic Paper Bag Printer 1-5 Colors Non Woven Plastic Bag Printing Machine Printing Machine

-

Single color mini flexo printing machine

Other Products

-

$5000.00 / set

$5000.00 / set -

$4000.00 / set

$4000.00 / set -

$1350.00 / set

$1350.00 / set -

$4000.00 / set

$4000.00 / set -

$5000.00 / set

$5000.00 / set -

$5000.00 / set

$5000.00 / set