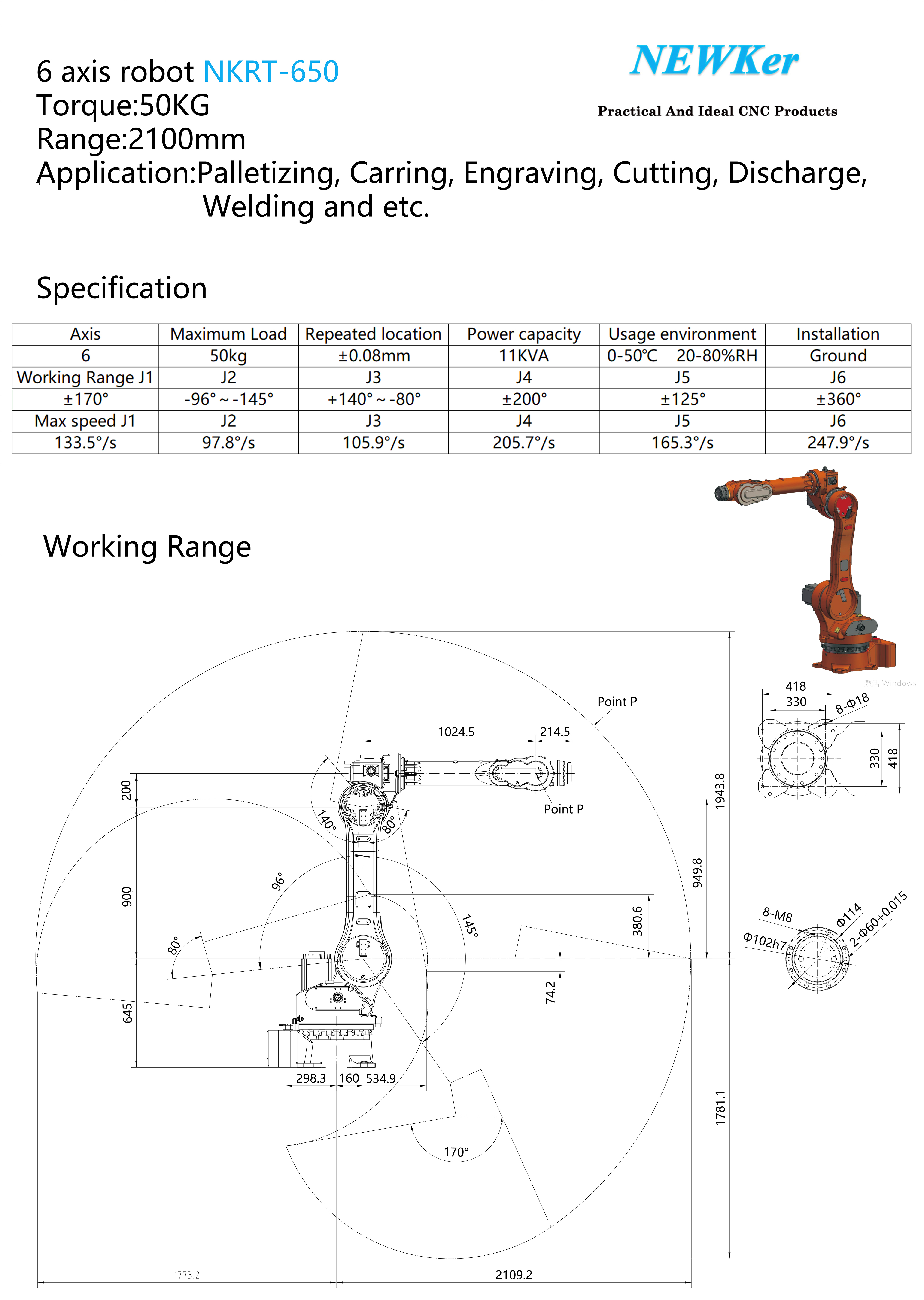

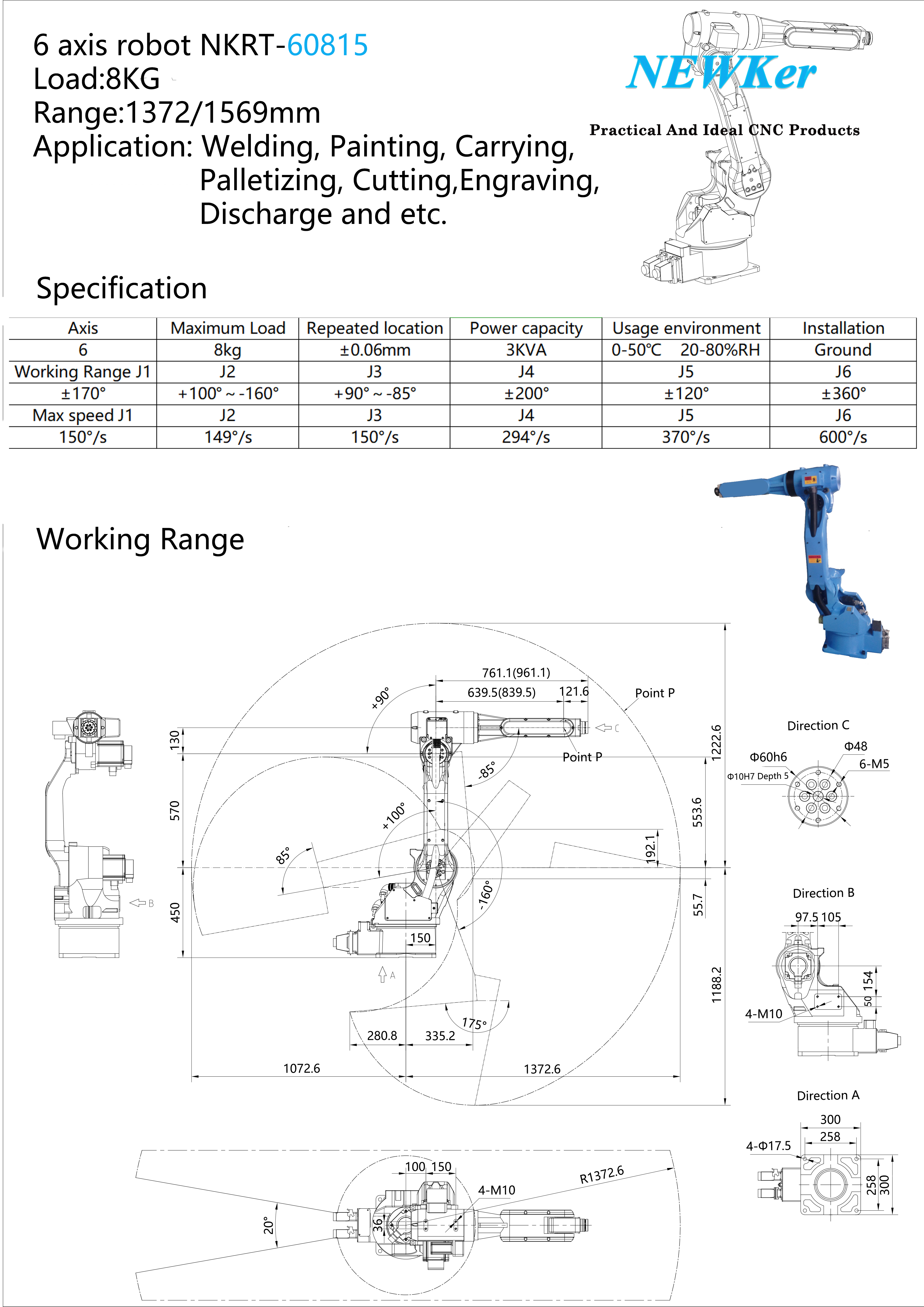

6 Axis Automat Cnc Robot Arm Milling/Articulated Robot Arm China

-

Supplier: Chengdu Newker CNC-Technology Co., Ltd. -

Region: Sichuan, China -

Contact: Ms Ashling Zhang -

Price: $7999.00 / 1 - 99 sets

$5999.00 / 100 - 199 sets

$3999.00 / >=200 sets -

Min. Order: 1 set

Product details

| place of origin; place of origin: | China | Health status: | new |

| port: | any port in China | program: | Teach-in function, G code |

| CPU: | ARM(32-bit)+DSP+FPGA | Voltage: | 220V |

| brand: | Newk | port: | 48 inputs 32 outputs |

| User Storage: | 256Mb (extended to 2G) | application: | Machine tool loading and unloading, teaching, playing chess, welding, assembling, painting, cutting, polishing |

| exhibit: | 8 inch true color LCD screen | Warranty: | 2 years |

| Supply capacity: | 10000 sets per month | Showroom location: | Turkey, Vietnam, Indonesia, Pakistan, India, Russia, Thailand, Kazakhstan, Kyrgyzstan, Tajikistan |

| speed: | 1.5m/s | Production capacity: | 99% |

| Dimensions (L*W*H): | optional | Function: | PLC+CNC+Teaching |

| Video external inspection: | if | Core Components Warranty: | 2 years |

| Marketing Type: | normal product | feature: | Stable and reliable performance |

| Applicable industries: | Hotels, Clothing Stores, Building Materials Stores, Manufacturing Plants, Machinery Repair Stores, Food and Beverage Plants, Farms, Restaurants, Home Use, Retail, Food Stores, Printing Stores, Construction Engineering, Energy and Mining, Food and Beverage Stores, Others, Advertising company | axis: | 6 axes |

| Weight (kg): | 68kg | Mechanical test report: | if |

| interface: | USB+RS232 communication port | Packaging Preview: | |

| Packaging Details: | 1. Industrial packaging (Design Humane CNC ROUTER FOR WOODWORKING NewKer-CNC NEW1000TDca series 5 axes): plastic bag + foam + carton + wooden pallet 2. Commercial packaging: plastic bag + foam + carton 3. According to customer requirements | Core components: | PLC, gearbox, motor, gear |

| payment terms: | L/C,Western Union,T/T |

Number of controller axes | Industrial automatic motoman arc welding robot 4-8 axis control panel (j1, j2, j3, j4, j5, j6) | Specify welding current: | AA/S | |

type: | Bus absolute and servo | Specify welding voltage: | VV/SS | |

Most programmed: | ±99999.999 | Start welding: | as * | |

Motor encoder: | 17-bit and 23-bit | End welding: | Auto Exposure* | |

Input and output points: | 48*32 input/output | Start wobble welding: | WS* | |

0-10V analog: | 2 channels 0-10V analog | End swing weld: | us | |

Operation: | Teaching, Responding, Remote | Joint movement: | MJ or MOVJ or GO | |

wireless function: | Connect mobile phone to send program | Motion od straight line: | ML or MOVL or G1 | |

RS 232 function: | RS232 connection with PC | Arc Movement: | MC or MOVC or G6 | |

USB features: | Update and send program | Specify the speed: | V=specified feed rate | |

Program Mode: | Teaching, G code, process parameters | Specify the ratio: | VJ= specified feed ratio | |

Sports function: | Point to point, line, arc | Track change speed: (smoothness | PL= | |

instruct: | Motion, logic, calculation, process, G-code in CNC | Start parallel translation: | serial number* | |

Coordinate System: | joint, user, tool, world | End parallel translation: | SF Express | |

PLC function: | Editing Ladder, 8000 steps | Read current position: | PK*** | |

Alarm information: | Emergency, drive, maintenance, arc start and coordinate error | Calculate the value of two positions: | PX***=PT***-PT*** | |

Limit function: | soft limit | Start your search: | ST*P* | |

Controller algorithm: | 1) Vertical multi-joint serial robot; 2) Vertical multi-joint parallelogram robot; 3) Vertical multi-joint L-shaped wrist robot; 4) Polar coordinate robot; 5) SCARA robot; 6) Delta Robot; 7) Special robots; | end search | southeast | |

password protection: | Multi-level random password protection | Direct command: | SX+/-,SY+/-,SZ+/-, | |

User macro program: | Have | Parallel values: | PX***=PX***+PX*** and PX***=PX***-PX*** | |

Electric gear function: | Have | G code: | Same as standard cnc controller | |

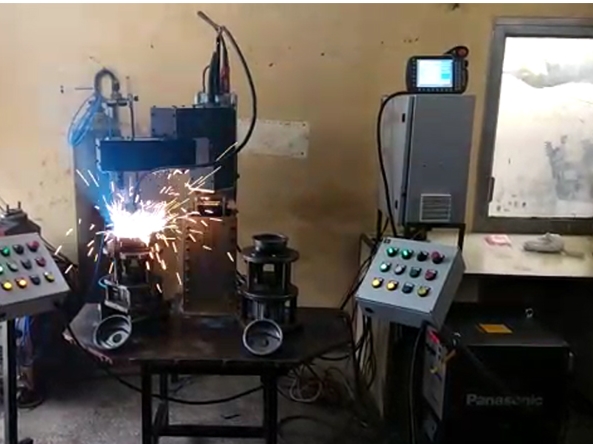

application: | Special robotic arms for welding, palletizing, painting, tending, laser cutting, etc. | Marco program description: | if..then;while;go;wat |

Never Crush machine, system with memory function (Abosolute function)

No need to install hard limit and homing (absolute function) in all kits of this 4-8 joint axis welding robot controller

Using the mobile phone to connect with the controller through the Wifi function, it is easier and more convenient to send programs (NewKer function)

G code program, only NewKer-CNC robot controller can be used with G code program such as cnc controller (NewKer function)

Teach-in function with process parameters for easier operation (NewKer function)

All PLC and macro programs are opened (NewKer function)

The controller only pulls out one cable for easier connection (bus type function)

Multi-level random password protection, more secure (NewKer function)

No need to install hard limit and homing (absolute function) in all kits of this 4-8 joint axis welding robot controller

Using the mobile phone to connect with the controller through the Wifi function, it is easier and more convenient to send programs (NewKer function)

G code program, only NewKer-CNC robot controller can be used with G code program such as cnc controller (NewKer function)

Teach-in function with process parameters for easier operation (NewKer function)

All PLC and macro programs are opened (NewKer function)

The controller only pulls out one cable for easier connection (bus type function)

Multi-level random password protection, more secure (NewKer function)

Virtual Reality

Virtual Reality

arm robot china arm robot chinaarm robot chinaarm robot china arm robot china arm robot chinaarm robot china arm robot china arm robot chinaArticulated Robot Arm Articulated Robot ArmArticulated Robot ArmArticulated Robot ArmMulti-joint robot arm Multi-joint robot arm Multi-joint robot arm Multi-joint robot armMulti-joint robot arm Multi-joint robot arm Multi-joint robot arm Multi-joint robot arm

Robotic ArmRobotic ArmRobotic ArmRobotic Arm Robotic Arm Automatic Robotic ArmRobotic Arm Robotic Arm Automatic Robotic Arm

axis robotaxis robotaxis robotaxis robotAxis Robot Axis Robot Axis Robot Axis RobotAxis Robot Axis Robot Axis Robot Axis Robot

CNC robotCNC robotCNC robotCNC robot CNC robot CNC robotCNC robot CNC robot CNC robot

CNC robotic armCNC robotic armCNC robotic armcnc robot cnc robot cnc robotcnc robot cnc robot cnc robot

cnc robot arm millingcnc robot arm millingcnc robot arm millingcnc robot arm millingcnc robot arm millingcnc robot arm millingcnc robot arm millingcnc robot arm millingcnc robot arm millingcnc robot arm millingcnc robot arm milling

VIEW MORE

You may like

-

China Laser Welding Robot/Industrial Welding Robot/6 Axis Automatic Welding Robot Arm

-

Industrial robot arm 6-axis/6-axis robot arm 10kg/concrete 6-axis high-speed robot arm

-

Factory direct sales Borunte 6-axis injection molding machine robot

-

Six-axis collaborative robotic arm manipulator for automatic welding

-

Factory direct small industrial robot SZGH-Arm 1832CO small industrial robot SCARA load robot

-

NEWKer stable and reliable six-axis manipulator industrial robot

-

Spraying Robot Arm 6 Axis Robot Arm 1950 mm Spraying Arm

-

SZGH 6-axis spraying industrial robotic arm collaborative robotic arm spraying robotic arm

-

South Korea's advanced industrial zero-delta robot

-

High Quality 6 Axis Robot Arm Durable Manipulator Articulated Used Arm Robot

Other Products

-

$299.00 - $350.00 / set

$299.00 - $350.00 / set -

$4999.00 - $6500.00 / piece

$4999.00 - $6500.00 / piece

Related Search

automatic cnc drilling and milling machine

5 axis vertical cnc milling machine

5 axis micro cnc milling machine

cnc robot arm

automatic cnc drilling machine

cnc and vertical milling machines

cnc machine vertical milling machine

automatic cnc butt welding machine

small cnc drilling and milling machine

cnc lathe and milling machine suppliers