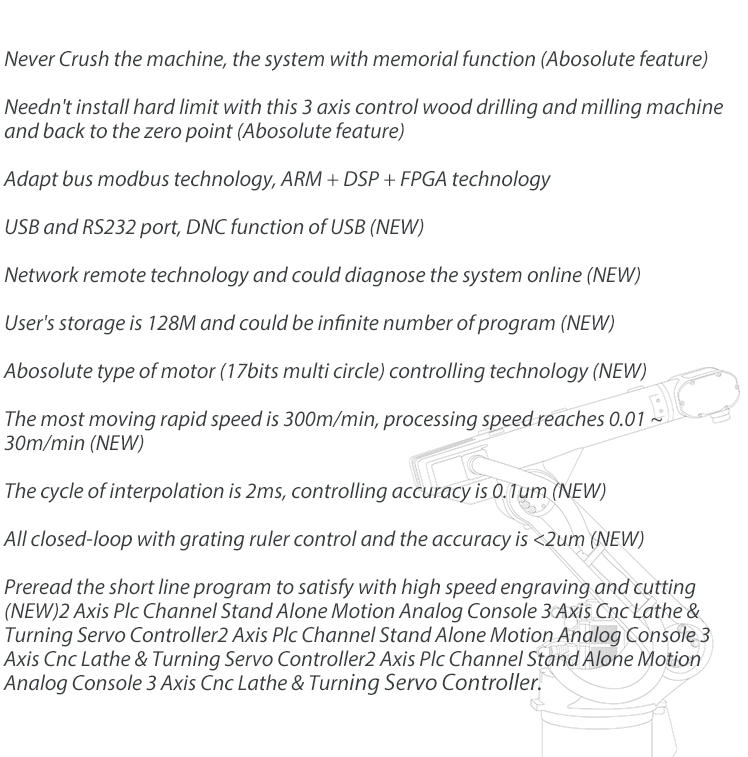

Absolute CNC remote control lathe and milling CNC servo system, similar to HNC and Fanuc

-

Supplier: Chengdu Newker CNC-Technology Co., Ltd. -

Region: Sichuan, China -

Contact: Ms Ashling Zhang -

Price: $350.00 / 1 - 19 sets

$320.00 / 20 - 49 sets

$299.00 / >=50 sets -

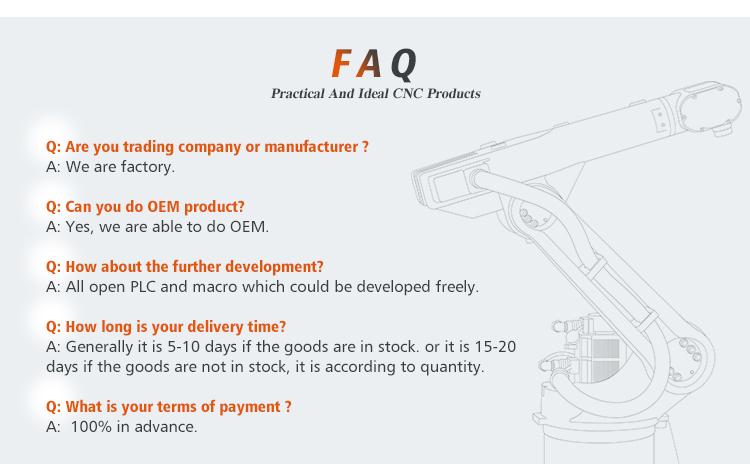

Min. Order: 1 set

Product details

| Origin: | Sichuan Province, China | Weight (KG): | 10 |

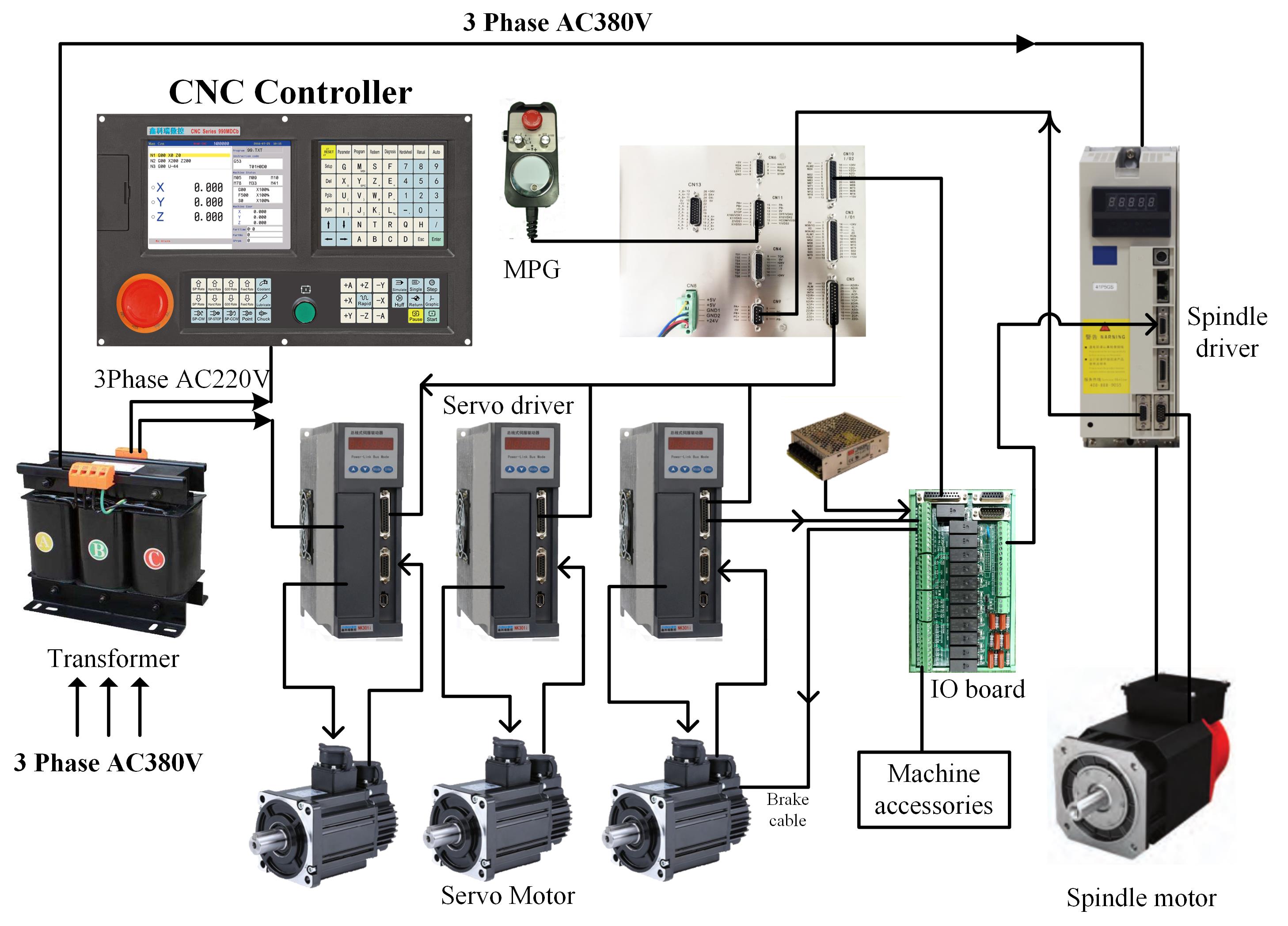

| Video outbound inspection: | if | CPU: | ARM(32-bit)+DSP+FPGA |

| speed: | 60m/min | Showroom location: | Turkey, Vietnam, Indonesia, Pakistan, India, Russia, Thailand |

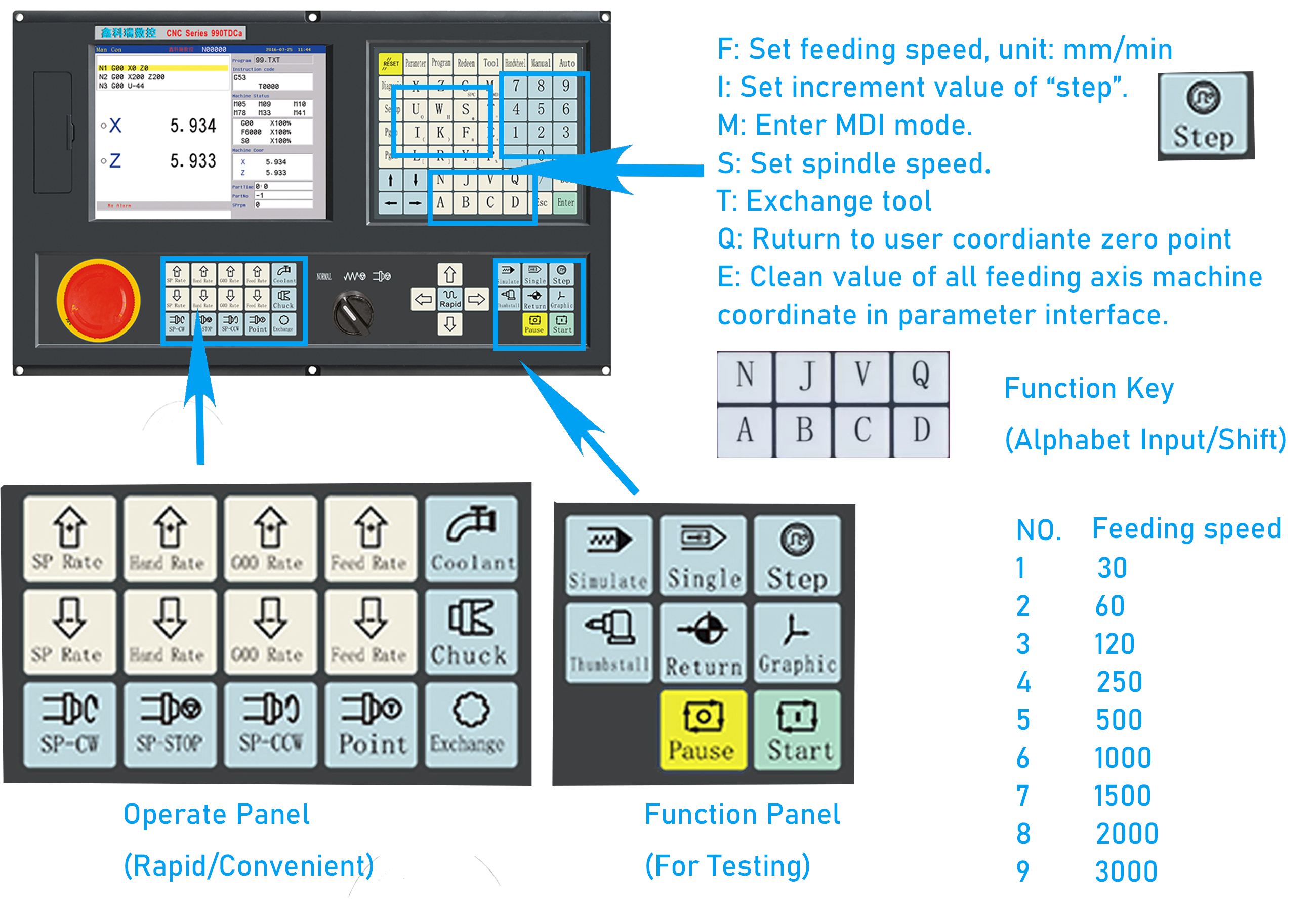

| port: | 56 input 32 output | exhibit: | 8 inches true color LCD screen |

| Mechanical test report: | if | Supply capacity: | 10000 sets per month |

| brand: | new customer | Core components: | PLC, CNC, OEM, macro program, DSP |

| payment terms: | L/C, Western Union, T/T | Health status: | new |

| Packaging Details: | 1. Industrial packaging (design humanized woodworking CNC router NewKer-CNC NEW1000TDca series 5 axes): plastic bag + styrofoam + carton + wooden pallet 2. Commercial packaging: plastic bag + styrofoam + carton 3. According to customer requirements | Warranty: | 2 years |

| application: | Lathes and Turning Centers | User repository: | 128MB |

| Marketing Type: | normal product | Package preview: | |

| port: | any port in China | After-sales service provided: | Video technical support |

| Applicable industries: | Clothing Stores, Building Materials Stores, Machinery Repair Shops, Manufacturing Plants, Food & Beverage Plants, Farms, Retail, Printing Shops, Construction, Energy & Mining, Others, Advertising Agencies | interface: | USB+RS232 communication interface |

| Dimensions (L*W*H): | 400*245*125 | Hole size: | 390*183 |

| Sub-board opening size: | A, B type is 390*130 C type is 390*183 | Function: | PLC+ tool magazine |

System functions | G code display | ||

Number of control axes | 3~4 (X, Y, Z, A) | Rapid positioning: | G00 |

Minimal programming: | 0.001 mm | linear interpolation | G01 |

Up to programming: | Thread cutting: ±99999.999mm | Thread cutting: | G02/03 |

Feed rate: | 0.001~15m/min | High speed deep drilling cycle | G73 |

Serial Manual: | One axis or two axes at the same time | Spot drilling cycle | G81, G82 |

Linear interpolation: | Linear, arc, thread interpolation | Wire cutting drilling cycle | G73 |

Tool compensation: | Compensation length, tool nose compensation | Boring cycle | G85, G86, G89 |

Spindle function: | Gear, dual analog control, rigid tapping | Tapping cycle | G74, G84 |

Handwheel function: | Panel, Handheld | program loop | G22, G800 |

Hand wheel processing: | Handwheel processing function | Local coordinate system: | G52 |

screen protector: | screen saver | check skip | G31, G311 |

Communication function: | RS232, USB interface | polar programming | G15/16 |

Compensation function: | Tool, clearance, lead screw, radius compensation | Metric and imperial programming | G20/21 |

Editing procedure: | Relative/absolute programming, mixed programming | program mode | G90/91 |

Read ahead function: | Pre-read 10,000 short lines | Processing plane | G17, G18, G19 |

Limit function | hard limit, soft limit | Workpiece coordinate system: | G54~G59 |

password protection: | Multi-level password protection | Tool Length Compensation | G43, G44, G49 |

input Output: | Input and output 24*24 | Tool Radius Compensation | G45~G48 |

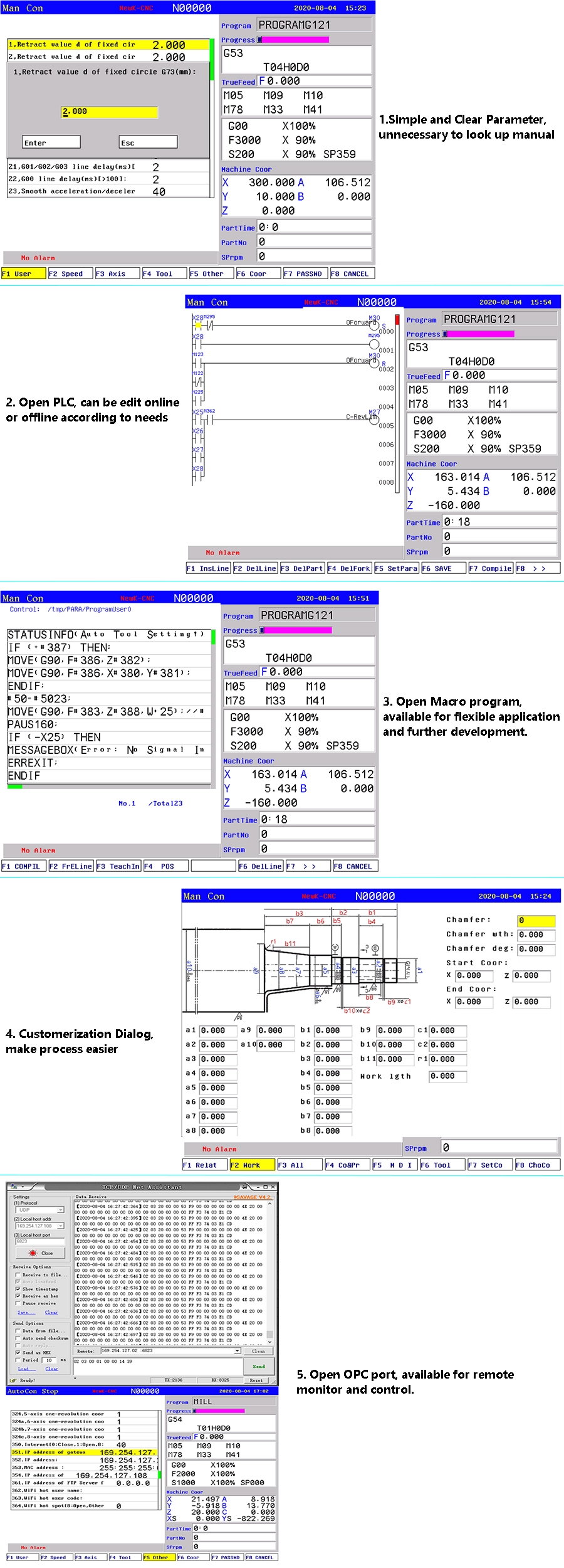

PLC program: | Fully open PLC design | C tool radius compensation | G40, G41, G42 |

Acceleration and deceleration control: | line, index | Precise Positioning/Continuous Path Machining | G60/G64 |

Number of encoders: | any setting | return to the starting point | G26, G261~G264 |

User macro program: | have | return fixed point | G25, G61, G60 |

Electric gear function: | have | return to reference point | G28, G281~G284 |

delay function | G04 | ||

Accessibility: | small, medium, medium |

Virtual Reality

Virtual Reality

VIEW MORE

You may like

-

F2100B plasma controller + lifter kit F2100B+F1621+JYKB-100-DC24V-T3+F1510T for plasma cutting machine cutting machine

-

Dytrees CNC USB MACH3 100Khz output board mach3 board 4 axis motion driver interface controller

-

Reiz A11 DSP mobile phone repair service

-

A02B-0321-B530 0i-Mate MD/TD CNC Fanuc machine tool original system controller

-

DSP Controller Accessory Richauto A11 A18 B11 B18 8IO Interface Board

-

Dytrees Hot Sale CNC USB MACH3 100Khz Breakout Board 4 Axis Interface Driver Motion Controller

-

A02B-0281-C071/C072 18i-MB/TB CNC Fanuc machine tool original system controller

-

Cheap portable cnc plasma flame sheet metal cutting machine prices

-

GSK 980TDc 5-axis CNC controller for lathe and turn-mill CNC systems

-

F2100B Portable CNC Flame/Plasma Cutting Controller System

Other Products

-

$4999.00 - $6500.00 / piece

$4999.00 - $6500.00 / piece -

$3999.00 - $7999.00 / set

$3999.00 - $7999.00 / set