F2100B plasma controller + lifter kit F2100B+F1621+JYKB-100-DC24V-T3+F1510T for plasma cutting machine cutting machine

-

Supplier: Lishui City Weicheng Bearing Limited Company -

Region: Zhejiang, China -

Contact: Mr Jane -

Price: $98.00 /piece -

Min. Order: 1 piece

| Model: | F2100B+F1621+JYKB-100-DC24V-T3+F1510T | Mechanical test report: | not available |

| USB type: | USB1.1 | Origin: | Zhejiang, China |

| Sales unit: | single product | Applicable industries: | Hotels, Clothing Stores, Building Materials Stores, Machinery Repair Shops, Manufacturing Plants, Food & Beverage Plants, Farms, Restaurants, Home Use, Retail, Food Stores, Printing Shops, Construction, Energy & Mining, Food & Beverage Stores, Other, Advertising company |

| control precision: | ±0.001mm | User storage space: | 256M |

| Weight (KG): | 10 | application: | Milling machines, flame/plasma cutting |

| Frequency: | 400 MHz | Video outbound inspection: | not available |

| Voltage: | 24V | brand: | wxya |

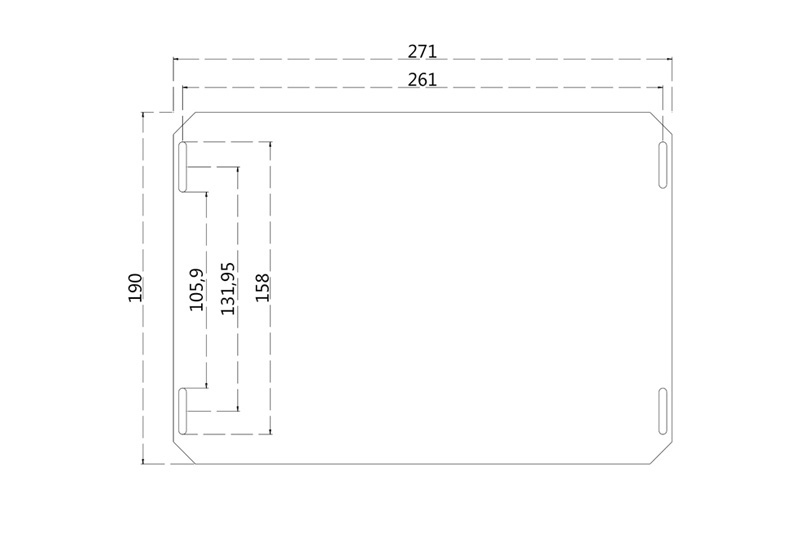

| Dimensions (L*W*H): | 300*204*93mm | Showroom location: | not any |

| Gross weight per piece: | 9.500 kg | Marketing Type: | New Products for 2021 |

| Core components: | PLC | After Warranty Service: | online support |

| Health status: | new | Local service locations: | not any |

| Package preview: | Display: | 7 inch | |

| Packaging Details: | After the packing box is packed, put it into the carton and wrap it with a green belt. | Warranty: | 1 year |

| Single pack size: | 40X30X10 cm |

F2100B

basic configuration

1. System name: F2100B

2. Display size: 7 inches, 16 million color bright LCD screen

3. Memory: 64M SDRAM

4. User storage space: 256M

5. Main frequency: 400MHz

6. USB type: USB1.1

7. USB quantity: 1 front interface, support 16GB or more U disk

8. Keyboard: PCB membrane keyboard

9. Chassis: fully enclosed structure, anti-electromagnetic radiation, static electricity

System Features

1. Chinese, English, Spanish, Portuguese, French, Russian, Danish, Korean, Japanese and other language menus, one-click language switching. In addition to Chinese and English, customer service is also required to provide language translation documents. In addition to Arabic, other languages can be supported.

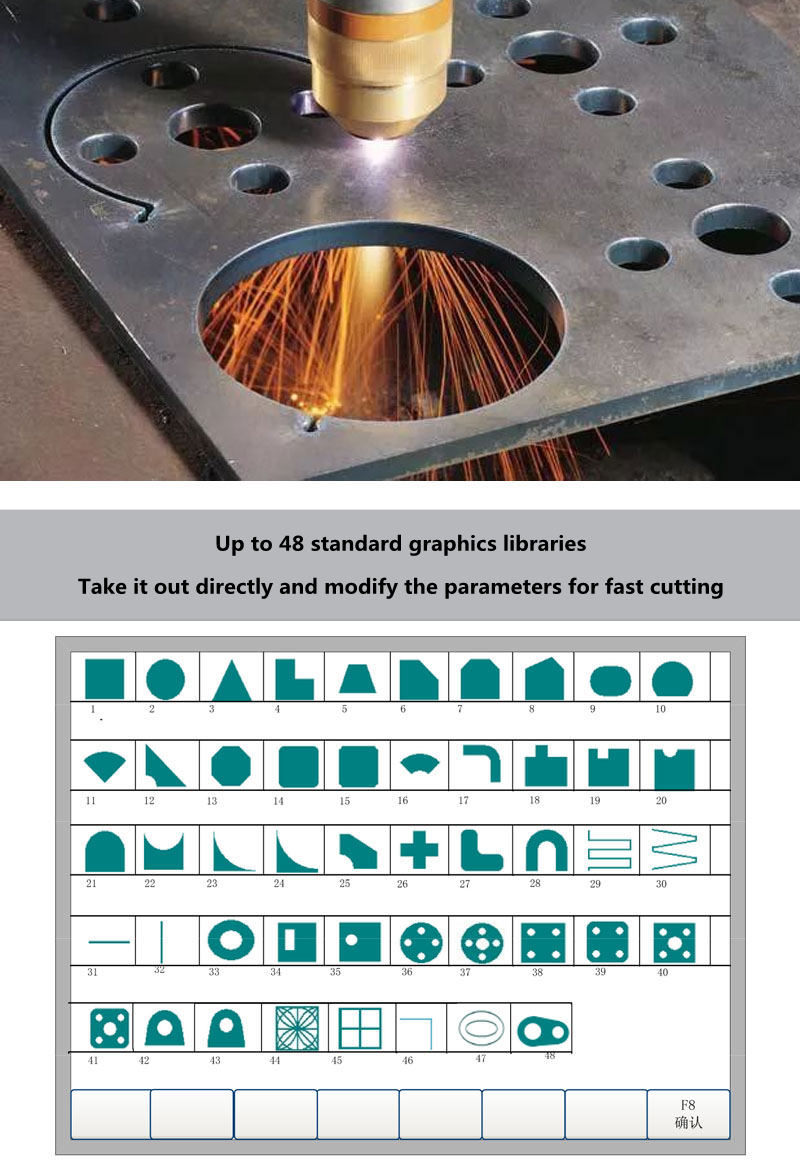

2. 48 kinds of commonly used graphic libraries (including grid graphics), you can choose to set the slice size and hole size.

3. Support EA code (G code) and various nesting software such as Fastcam, Freenet, Smartnest, IBE, etc. Support suffix TXT, CNC, NC, MPG, B3 and other G codes.

4. Support common commands of ESSI code.

5. The compact keyboard design makes manual document input more comprehensive.

6. Graphic scale, rotation, mirror image.

7. Graphics can be arranged in matrix, alternately and stacked.

8. The original size of the workpiece and the size of the cutting seam are displayed at the same time, which is intuitive and convenient.

9. Graphic steel plate calibration, any steel plate edge can be used as the calibration edge.

10. Customizable coordinate system, supporting all eight possibilities of two-dimensional coordinates.

11. The type (normally closed or normally open) and number of all input and output ports can be customized.

12. Self-diagnosis system for all IO and key states, convenient for inspection and troubleshooting.

13. The front U disk interface is convenient for program transmission.

14. U-disk upgrade system is adopted, which is convenient, simple, practical and free for lifetime upgrade.

15. Support system backup and system recovery functions, system recovery can only restore the operating system, or restore to the factory state.

16. All functions and processes of the entire system can be upgraded online to eliminate after-sales worries.

17. A single or all processing files can be imported and exported.

18. Parameter backup and parameter recovery.

19. Support 4 modes of oxy-fuel, plasma, powder coating and demonstration.

20. Various processing parameters are complete, which can meet different process requirements.

21. Oxyfuel and plasma IO are controlled separately.

22. Oxy-fuel automatic tuning, two-stage preheating, three-stage piercing.

23. Plasma arc voltage feedback, positioning feedback, and corner auto-off arc voltage adjustment are high.

24. The controller with suffix T comes with integrated arc voltage height control function (THC).

25. Built-in plasma arc voltage automatic/manual height adjustment function: it can display the actual arc voltage and set arc voltage, set arc voltage height adjustment parameters, detect collision/positioning success signal, control arc voltage signal, and position test.

26. Plasma arc voltage control supports two closed arc voltage adjustment methods: speed and distance, making the machine more stable and safe.

27. Support trimming and reduce the preheating time of thick steel plates.

28. Real-time acceleration and deceleration during exercise.

29. According to the thickness of the steel plate, the speed can be automatically limited at the corner to effectively prevent overheating.

30. Manually select the starting line or select the pierce point.

31. Dynamic and static processing graphics display, graphics zoom in/out, and dynamically track the cutting point in the enlarged state.

32. DSP high-speed, high-precision interpolation control, high-speed operation, stable operation, low noise.

33. Arbitrarily set the initial speed, rising and falling speed time.

34. With power-off and breakpoint protection memory function.

35. The function of "offset cutting" can avoid the waste of plates caused by wrong calculation of layout.

36. Different management rights and corresponding passwords can be set to protect the rights and interests of equipment manufacturers.

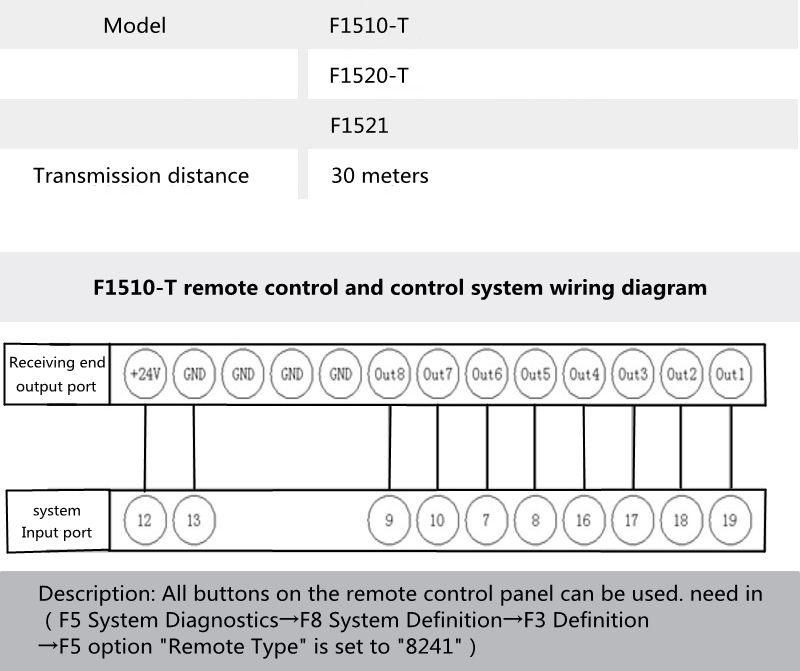

37. Support P2P mode or BCD (8421) and serial RS232 mode remote control.

38. Support plasma dynamic perforation function.

39. Count the number of processed pieces, running time, perforation times and other information.

F1621

Product parameters

1. Model: F1621

2. Working voltage: DC24±10%, 60W

2. Lifting motor: DC24V motor, 45W

4. Drive mode: PWM stepless speed regulation, H-bridge MOS drive

5. Working temperature: 0-50℃

6. Positioning method: protective cap positioning or proximity switch positioning

7. Arc voltage range: 0V-600V

8. Sampling accuracy: 0.2V

9. Control accuracy: 0.5V

10. Voltage division ratio: 100:1

11. Lifting speed: 8000MM/MIN

12. Sensitivity: adjustable through parameters

13. Protection: overload protection

14. Over temperature protection

15. Short circuit protection

16. Undervoltage protection

17. Power supply anti-reverse connection protection

Features

1. Two initial positioning methods: 1. Proximity switch positioning 2. Protective cap positioning.

2. Automatic arc pressure height control: Automatically track the height of the steel plate during cutting, and always keep the torch at a fixed height from the steel plate to ensure cutting quality.

3. Automatic lifting protection cutting torch: 1. After hitting the torch, it will automatically lift the torch. 2. After the cutting is completed, the gun will be automatically raised and lowered.

4. Multiple operating modes: 1. Automatic operation 2. Manual operation.

5. Arc voltage monitoring: double arc voltage display, which is convenient for users to monitor the height during cutting in real time.

6. Intelligent adjustment of arc voltage: After multiple collisions, the set arc voltage will be automatically increased.

7. Dynamic perforation: at the moment of perforation, the torch rises. Protect cutting gun from splash damage.

8. Collision feedback: After a collision, the collision signal is immediately fed back to the control system.

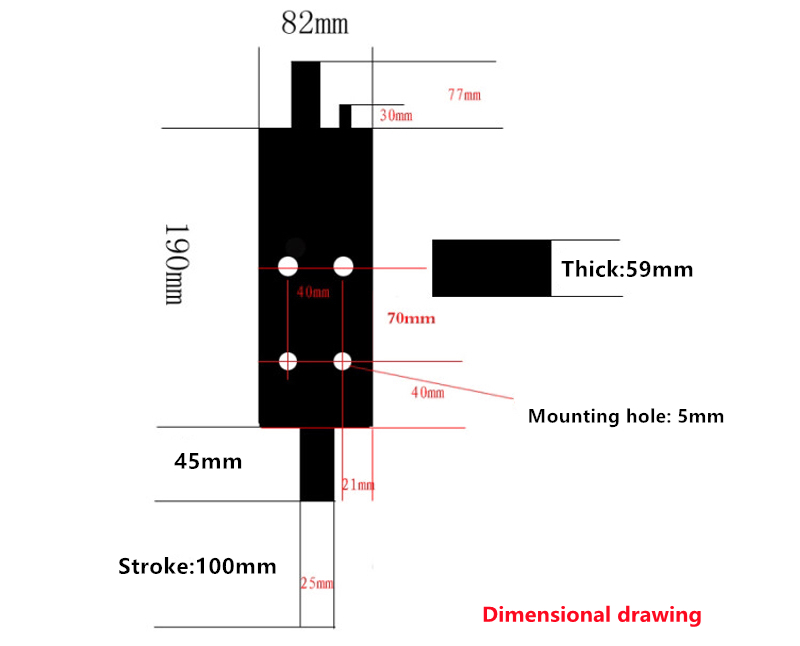

Model: JYKB-100-DC24V-T3 plasma cutting, 2400mm/min

Related parameters

1. 304 stainless steel T-screws

2. Including fixture (cutting torch range 12mm-38mm)

3. The lifting mechanism has the function of internal plasma arc starting and positioning

4. The main aluminum plate, the thickness of the upper and lower aluminum plates is 8mm, and the machining center is formed at one time

5. Four-pin aviation plug

6. Color: shell black plastic spraying

7. Working stroke: 100mm

8. Working voltage: DC24V

9. Load weight: 3kg

10. Size: length 320*width 80*height 60

11. The size of the installation hole is long: the center distance between the left and right holes is 40mm, and the center distance between the upper and lower holes is 70mm

Avionics Plug Definition

1 pin --MOT+; (motor positive)

2-pin --MOT+; (motor negative pole)

3 pins--zero; (positioning normally open zero-crossing signal output)

4-pin --com; (Position normally open COM signal output)

Note: The lifting body has a built-in limit (using a 10A reverse diode), no need to re-wiring

-

Dytrees CNC USB MACH3 100Khz output board mach3 board 4 axis motion driver interface controller

-

Absolute CNC remote control lathe and milling CNC servo system, similar to HNC and Fanuc

-

Reiz A11 DSP mobile phone repair service

-

A02B-0321-B530 0i-Mate MD/TD CNC Fanuc machine tool original system controller

-

DSP Controller Accessory Richauto A11 A18 B11 B18 8IO Interface Board

-

Dytrees Hot Sale CNC USB MACH3 100Khz Breakout Board 4 Axis Interface Driver Motion Controller

-

A02B-0281-C071/C072 18i-MB/TB CNC Fanuc machine tool original system controller

-

Cheap portable cnc plasma flame sheet metal cutting machine prices

-

GSK 980TDc 5-axis CNC controller for lathe and turn-mill CNC systems

-

F2100B Portable CNC Flame/Plasma Cutting Controller System

Other Products

-

$14.86 / set

$14.86 / set -

$9.97 / piece

$9.97 / piece -

$19.50 / piece

$19.50 / piece -

$220.00 / piece

$220.00 / piece