GSK 980TDc 5-axis CNC controller for lathe and turn-mill CNC systems

-

Supplier: Fancy machinery Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Zhu -

Price: $1400.00 /set -

Min. Order: 1 set

Product details

| port: | Shenzhen Port | payment terms: | L/C,D/P,D/A,T/T |

| Supply capacity: | 200 sets per month | Applicable industries: | Mechanical Repair Shop, Manufacturing Plant |

| weight: | 6 | Packaging Details: | Carton |

| application: | Lathes and Turning Centers | Mechanical test report: | if |

| Showroom location: | Malaysia | Packaging Preview: | |

| Core components: | programmable logic controller | Warranty: | 1 year |

| Video external inspection: | if | place of origin; place of origin: | Guangdong, China |

| brand: | GlaxoSmithKline | Marketing Type: | New Products 2020 |

Product Description

Please click here to contact us

GSK 980TDc CNC controller for lathes

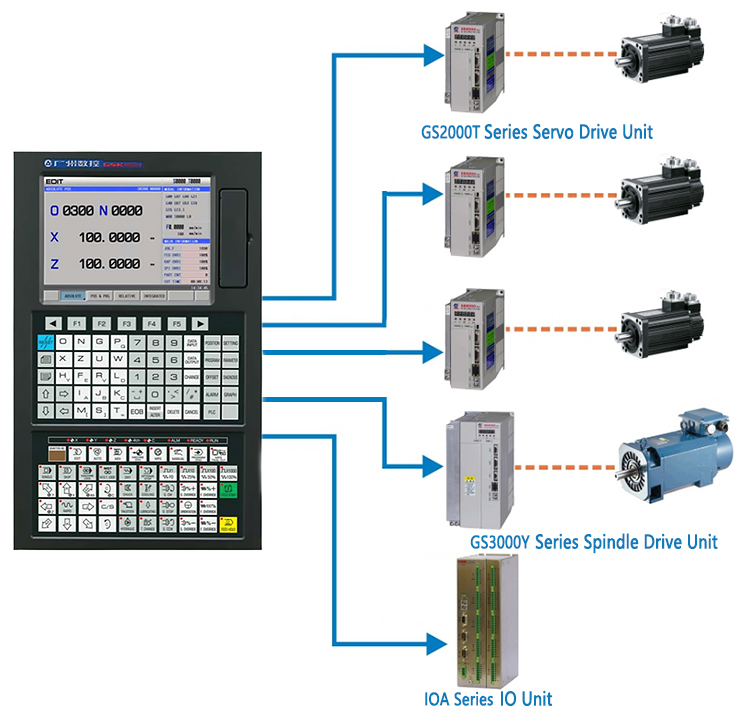

GSK980TDc is a newly upgraded software. Its software and hardware are based on GSK980TDb. It has a horizontal and vertical structure. It is equipped with an 8.4-inch color LCD display, 5 feed axes (including C axis), 2 analog spindles, and the minimum input increment is 0.1um. Using graphical interface and friendly man-machine operation window, it can realize PLC online display, real-time monitoring and MPG trial cutting functions. As an upgraded product of GSK980TDb, GSK980TDc CNC turning is a better choice.

Technical Features

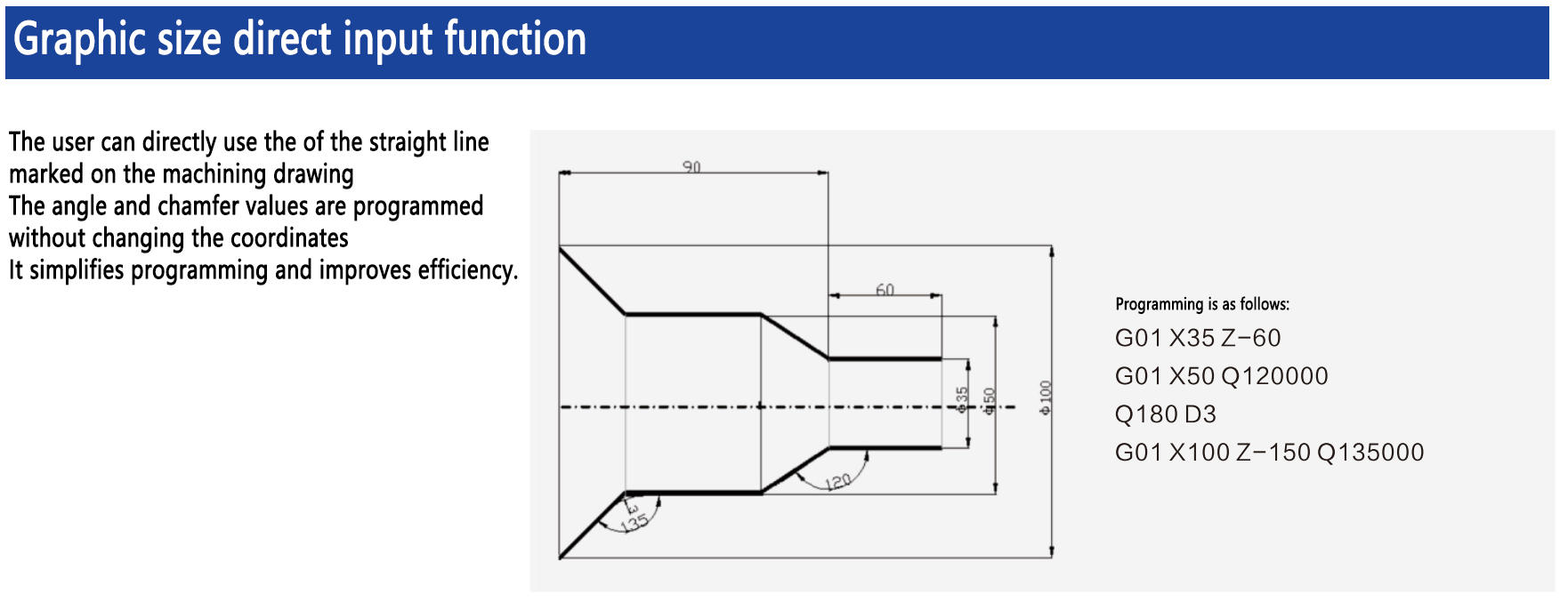

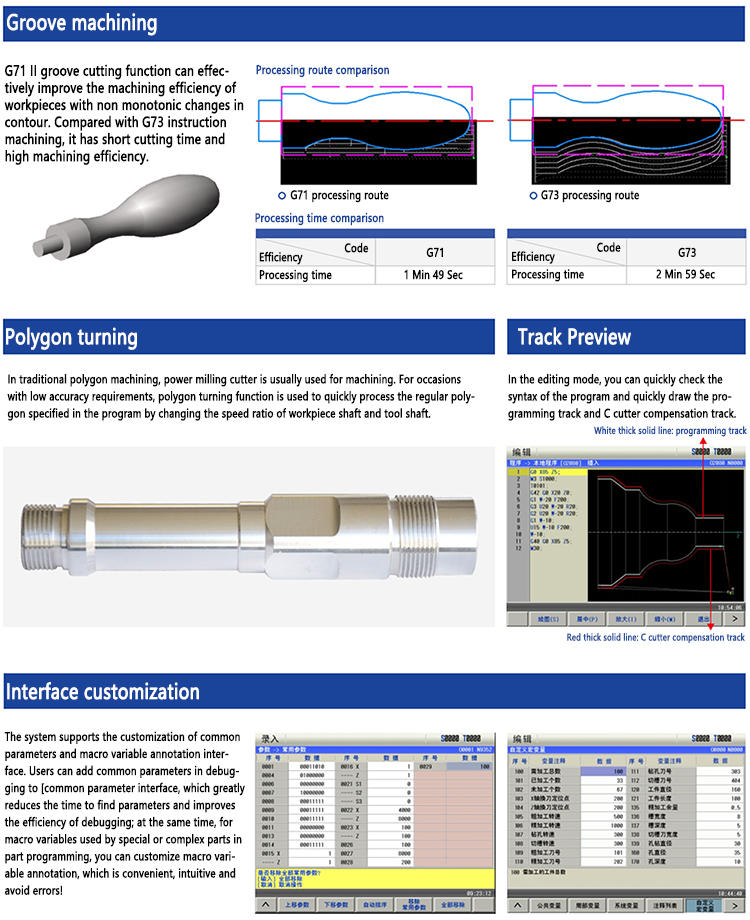

○5 feed axes and 2 analog spindles; with MPG trial cut, teaching, and MPG interruption functions;○The minimum control accuracy is 0.1um, and the maximum moving speed is 60m/min;○With online machine tool debugging wizard, auxiliary programming, interface customization, direct input of graphic dimensions, polygon turning and other functions;○Standard GS2000T-N series strong overload servo unit, servo motor position feedback using 5000 line encoder;

○40m program storage space, 10,000 part programs, support U disk program processing;

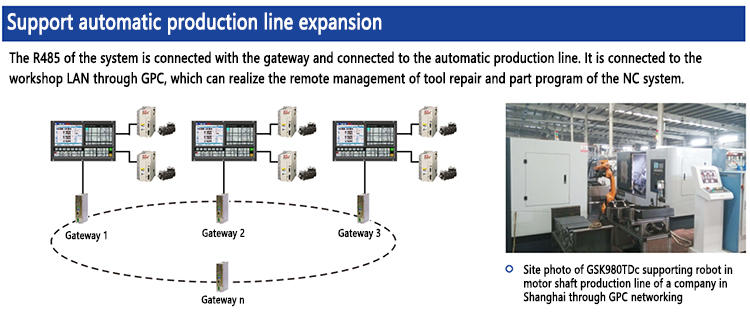

○Built-in PLC, online display of ladder diagram, real-time monitoring, expandable serial port I/0 unit;

○8. 4-inch true color LCD, support Chinese, English, Russian and other multi-language display

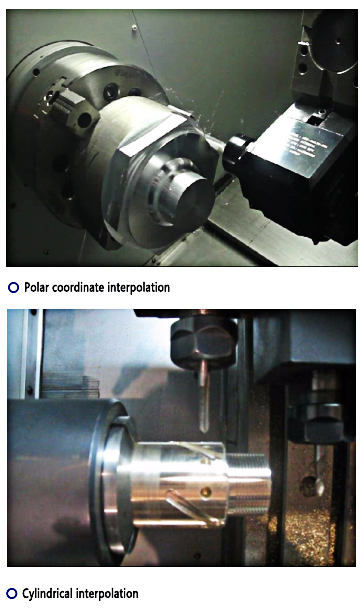

The system has 5 feed axes and 2 analog spindles. When adapting to the servo spindle, it can realize spindle orientation, rigid tapping, cylindrical interpolation, and polar coordinate interpolation to meet the requirements of turning and milling composite processing.

technical parameter | ||||||

thing | Specification | |||||

Number of control axes | Maximum number of control axes: 5 axes | |||||

Maximum number of linkage axes: 5 axes (linear interpolation), 2 axes (circular interpolation) | ||||||

Number of PLC control axes: 5 axes | ||||||

Coordinate value (system) and size | Workpiece coordinate system (G50), local coordinate system, workpiece coordinate system 1~6 (G54~G59) | |||||

Coordinate plane selection | ||||||

Position command range: ±99999999 x min input unit | ||||||

Absolute/incremental programming, diameter/radius programming, inch/metric conversion, linear/rotary axes | ||||||

G function | Contains 69 G commands, including rapid positioning, linear interpolation, circular interpolation, cylindrical interpolation, thread cutting, polar coordinate interpolation, polygon turning, rigid tapping, pause, drilling, tool compensation, macro program calling, Jump, loop, tilt axis control, thread repair, etc. | |||||

Feed function | Fast: μ grade (IS-B) 0mm/min~60000mm/min 0.1μ (IS-C) 0mm/min~24000mm/min | |||||

Fast zoom: F0, 25%, 50%, 100% a total of four real-time adjustment | ||||||

Cutting feed rate: μ grade (IS-B) 0mm/min~30000mm/min 0.1μ (IS-C) 0mm/min~24000mm/min | ||||||

Feedrate override: 0~150%, sixteen levels of real-time adjustment | ||||||

Rapid/cutting feed acceleration and deceleration: linear type and S type. The start speed, end speed and acceleration/deceleration time of acceleration and deceleration are set by parameters. | ||||||

thread cutting | Thread type: equal pitch straight thread taper thread/end thread/arc thread, variable pitch straight thread/taper thread/end thread and other tooth tip width variable lead threads | |||||

Threaded head: 1-99 | ||||||

Pitch: 0.01mm~1000mm (metric thread) or 0.06 teeth/inch~2540 teeth/inch (inch thread) | ||||||

Thread cutting acceleration and deceleration: linear type, exponential type, S type can be set | ||||||

Thread back end: can set back length, angle and speed characteristics | ||||||

Spindle function | Spindle speed: can be given by S code or PLC signal, the speed range is 0~9999rpm | |||||

Spindle override: 50%~120%, eight levels in total, real-time adjustment | ||||||

2 channels of 0V~10V analog voltage output, support flexible tapping/rigid tapping | ||||||

2-way spindle encoder feedback, the number of spindle encoder lines can be set | ||||||

Tool function | Tool length compensation (tool compensation): 32 groups | |||||

Tool wear compensation: 32 groups | ||||||

Tool life management: 32 groups (8 tools/group) | ||||||

Tool nose radius compensation (C type) | ||||||

Tool setting method: fixed point tool setting, trial cutting tool setting, reference point return tool setting, automatic tool setting, coordinate recording function | ||||||

Tool compensation execution mode: modify coordinate mode, tool moving mode | ||||||

M function | Special M codes (M 00, M 01, M 02, M 30, M 98, M 99), other M codes are defined by PLC | |||||

13 basic instructions, 27 functional instructions | ||||||

PLC program online display and real-time monitoring; support PLC alarm and PLC alarm | ||||||

Support multiple PLC programs, select the currently running PLC program | ||||||

Basic I/O: 980TDc: 41 inputs/36 outputs; 980TDc-H: 61 inputs/44 outputs | ||||||

| Expandable Serial I/O Unit (Optional): IOA-01T: 24-point input, 16-point output, 4-channel analog voltage output IOA-02T: 40 points of input, 24 points of output, 8 analog voltage outputs and 4 analog voltage inputs | ||||||

Program capacity: 40M, 10000 programs (including subprograms and macro programs) | ||||||

Edit Mode: Full Screen Editing | ||||||

Editing function: program/program segment/word retrieval, modification, deletion, copy, paste | ||||||

MDI allows input and manipulation of 10 blocks | ||||||

Support macro/subprogram calling, allowing 4 levels of subprogram nesting | ||||||

calculator | ||||||

Assisted programming | ||||||

Program check function | Track preview, graphic simulation, dry run, machine lock, auxiliary function lock, single-segment operation, stored stroke detection | |||||

Simplified programming capabilities | Canned cycle, multiple canned cycles, rigid tapping, direct input of drawing dimensions, automatic chamfering, statement-based macro programming | |||||

Backlash compensation: 0mm~2mm (or 0inch~0.2inch), the backlash compensation method and frequency are set by parameters | ||||||

Memory pitch error compensation: a total of 1024 compensation points, parameter settings for each axis compensation point | ||||||

8.4 inch LCD | ||||||

Support Chinese, English and other language display | ||||||

The processing track is displayed, the processing track can be enlarged and reduced in real time, and the font of the program content can be enlarged or reduced. | ||||||

Position, Program, Tool Compensation, Alarm, Parameter, Setting, Graph, Diagnosis, Ladder Diagram, Help | ||||||

Operation mode: edit, automatic, input, mechanical zero return, MPG/single step, manual, program zero return, MPG trial switch\zero return | ||||||

Level 6 operation authority management | ||||||

Up to 32 timed shutdowns can be set | ||||||

Program switching, parameter switching | ||||||

MPG breaks, teaching | ||||||

Machine function debugging, machine fault diagnosis | ||||||

Regular maintenance function | ||||||

USB: U disk file operation, U disk file direct processing, PLC program support, system software U disk upgrade | ||||||

RS 232: Bidirectional transmission of parts programs, parameters and other files, import and export of screw compensation parameters, support PLC program update | ||||||

security function | Emergency stop, hardware travel limit, software travel check, data backup and recovery | |||||

Electrical Interface | 5 control axes (including C axis), 2 analog voltage outputs, 1 encoder feedback input, 1 electronic handwheel input (support handheld electronic handwheel, 980tdc-h supports 2 handwheels), 1 RS 232 , 1 USB-H, 41 input/36 output (980tdc-h: 61 input/44 output) | |||||

GSK980TDc(W×H×D)420×260×150mm | ||||||

GSK980TDc-V (W×H×D) 260×420×150mm | ||||||

GSK980TDc-B (W×H×D) | 445×345×182mmmm | |||||

(Host) 400×200×130mm | MPU03AT (with handwheel operation panel) 400×200×135mm | |||||

MPU03BT (without handwheel operation panel) 400×200×135mm | ||||||

more products

VIEW MORE

You may like

-

F2100B plasma controller + lifter kit F2100B+F1621+JYKB-100-DC24V-T3+F1510T for plasma cutting machine cutting machine

-

Dytrees CNC USB MACH3 100Khz output board mach3 board 4 axis motion driver interface controller

-

Absolute CNC remote control lathe and milling CNC servo system, similar to HNC and Fanuc

-

Reiz A11 DSP mobile phone repair service

-

A02B-0321-B530 0i-Mate MD/TD CNC Fanuc machine tool original system controller

-

DSP Controller Accessory Richauto A11 A18 B11 B18 8IO Interface Board

-

Dytrees Hot Sale CNC USB MACH3 100Khz Breakout Board 4 Axis Interface Driver Motion Controller

-

A02B-0281-C071/C072 18i-MB/TB CNC Fanuc machine tool original system controller

-

Cheap portable cnc plasma flame sheet metal cutting machine prices

-

F2100B Portable CNC Flame/Plasma Cutting Controller System

Other Products

Related Search

2 axis cnc lathe controller

cnc controller for machin center suppliers

controller board for lathe machine suppliers

5 axis cnc controller

dsp controller for cnc router

motor controller for cnc

5 axis cnc controller board suppliers

bluetooth remote control for steering

joystick controller for electric wheelchair

game control for headrest suppliers