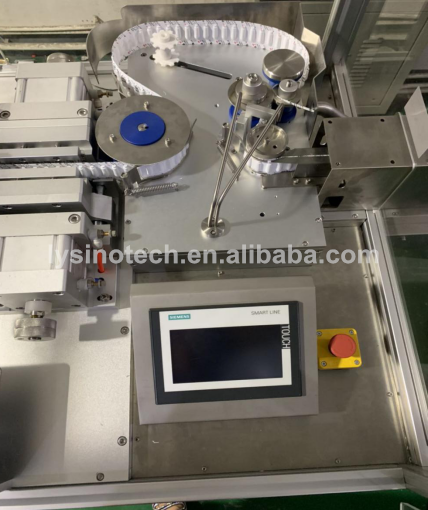

Pharmaceutical industry high-speed throttling machine production line

-

Supplier: Liaoyang Sinotech Technology Development Co., Ltd. -

Region: Liaoning, China -

Contact: Ms Susan Guo -

Price: $40000.00 /set -

Min. Order: 1 set

| Automatic level: | fully automatic | Showroom location: | not any |

| Core components: | PLC, water pump | Movie: | PVC\PE (thickness 0.15mm) |

| Machine weight: | 2500 kg | Weight (kg): | 780 |

| capacity: | 10000-12000pcs/hour | Mechanical test report: | if |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | usage: | Liquid/Cbd Oil |

| Dimensions (L*W*H): | (L) 7800 mm (W) 1800 mm (H) 2100 mm | Core component warranty: | 1 year |

| Warranty: | 1 year | Applicable industries: | Food and Beverage Factory, Advertising Agency |

| Health status: | new | Voltage: | 380v/220 can be customized |

| brand: | Chinese, Chinese | Video shipment inspection: | if |

| strength: | 9.7kw | product name: | Suppository Production Line |

| use: | Various shapes such as bullet type and duckbill type | place of origin; place of origin: | Liaoning, China |

| Marketing Type: | New Products 2020 | port: | Suppository Filling Machine Shanghai Port |

| Package preview: | Applies to: | Various shapes such as bullet type and duckbill type | |

| Main selling points: | easy to operate | Filling volume: | 0.5-5 grams |

| Packaging Details: | Export standing wood packaging suppository filling machine | Supply capacity: | 20 sets per month |

Sinotech-15 fully automatic suppository production line is suitable for the production of special shapes such as bullet head and duckbill, and meets the production of various suppositories. (According to the mold specifications required by customers).

Model | Chinese Section Seven |

capacity | 10000-12000pcs/hour |

volume | 0.5-5 grams |

Filling accuracy | <±2% |

tank volume | 50L |

working pressure | ≥0.6Mpa |

Air consumption/min | 1.5 cubic meters |

Water consumption/hour | 50 KGS (recycled) |

total power | 9.7KW |

1. High filling accuracy

2. Combination structure of triangular knife and point line knife

3. Servo transmission cutting system

4. There is no sticky material on the pump in the filling part

5. Stirring tank speed control system

6. Segmented cooling system

7. PLC detection system

8. The filling parts are equipped with anti-static system

9. Preheat the seal and shear at 3 degrees

1 Product quality

All products are guaranteed for one year, and if there is any problem during the warranty period, our company will repair it for free.

2 Spare Parts Replacement

The first mold is free, more than 50% off, multiple orders are discounted.

3 Technical Services

We can provide design, installation and commissioning services or remote maintenance teaching.

4 Ship the goods to the nearest port

We will arrange shipment and deliver the goods to your nearest port, saving time and cost.

5 detailed product information

Provide pictures, videos, instructions and product brochures.

6 timely reply

24-hour hotline, we will reply emails within 12 hours.

-

Leadtop Automatic Suppository Machine Suppository Shell Making Machine Vaginal Suppository Production Machine

-

Fully Automatic Suppository Machine/Suppository Filling and Sealing Equipment

-

Semi-automatic bullet suppository filling and sealing machine

-

Pharmaceutical non-PVC soft bag physiological saline intravenous injection filling and sealing production line

-

Suppository Mold Production Line Bottle Cylinder Power Packaging Technology Sales Video Computer Stand Liquid Weight

-

Tablet pharmaceutical packaging, automatic stick packaging machine

-

Blister capsule tablet defoaming machine for capsule and tablet recycling in China factory

-

Bottle filling production line capsule counting labeling machine line

-

SupLab-2 suppository filling and sealing machine

-

Automatic blister packaging machine with hard capsules DPB-140

Other Products

-

$2700.00 / set

$2700.00 / set