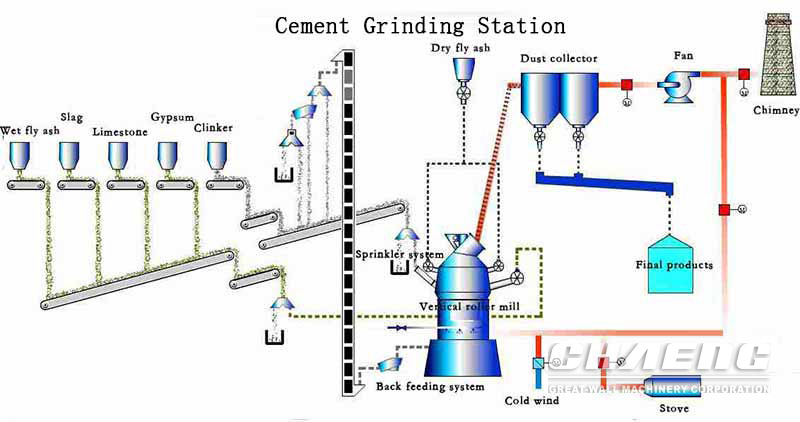

cement mill/clinker grinding station/cement grinding plant

-

Supplier: Xinxiang Great Wall Machinery Co., Ltd. -

Region: Henan, China -

Price: $100000.00 /piece -

Min. Order: 1 piece

| Key words: | Cement clinker grinding station | Voltage: | 220/380/440v |

| Name: | Grinding and granulating blast furnace slag production line | price: | Negotiable |

| payment terms: | L/C, D/P, D/P, T/T | Supply capacity: | 30 sets/year fine-grained blast furnace slag production line |

| capacity: | 100,000-1.5 million tons/year | Packaging Details: | standard package or bare package |

| Warranty: | 3 years | raw material: | Clinker, cement, gypsum, pozzolan, GGBS, slag, |

| brand: | long | product name: | Clinker Grinding Station |

| Dimensions (L*W*H): | L*W*H): Can be customized | advantage: | high performance |

| strength: | 25-30 kWh/ton | Host: | GRMK cement vertical mill |

| After-sales service provided: | Engineers available to service machinery overseas | port: | any port in china |

| Health status: | new | weight: | 300t-3000t |

| Origin: | Henan, China | Certification: | ISO9001 |

| Production capacity: | 20--380 tons/hour | spare parts: | Happy for a long time |

| Shipping Details: | 2-2.5 months after the contract takes effect | application: | Slag, cement, stone, industrial waste |

CHAENG can undertakeEPCturnkey serviceCement clinker grinding stationAnnual output200,000--2 milliontons. So far, CHEANG has successfully establishedmore than 120The grinding plant includes: cement clinker grinding plant, GGBFS slag powder production line, etc.

| Model | Disc diameter(mm) | Standard capacity Q (t/h) | Motor (kW) |

|---|---|---|---|

| GRMR22 | 2,200 | 65-75 | 710 |

| GRMR24 | 2,400 | 75-85 | 800 |

| GRMR26 | 2,600 | 85-95 | 900 |

| GRMR28 | 2,800 | 100-110 | 1000 |

| GRMR30 | 3,000 | 110-120 | 1120 |

| GRMR33 | 3,300 | 140-150 | 1400 |

| GRMR36 | 3,600 | 180-190 | 1800 |

| GRMR38 | 3,800 | 200-210 | 2000 |

| GRMR40 | 4,000 | 230-250 | 2240 |

| GRMR43 | 4,300 | 260-280 | 2500 |

| GRMR46 | 4,600 | 330-350 | 3150 |

| GRMR48 | 4,800 | 350-370 | 3350 |

| GRMR50 | 5,000 | 370-400 | 3550 |

| GRMR53 | 5,300 | 440-470 | 4200 |

| GRMR56 | 5,600 | 470-500 | 4500 |

| GRMR60 | 6,000 | 550-600 | 5300 |

| GRMR65 | 6,500 | 670-720 | 6300 |

| GRMR70 | 7,000 | 850-900 | 8000 |

CHAENG can provide a variety of cement grinding solutions, and choose according to the actual situation and needs of customers:

| project | Option One Closed circuit ball milling system | Option II Combined Grinding System | third solution Vertical roller mill fine grinding system | |

|---|---|---|---|---|

| cement type | P·O4 2.5 | P·O4 2.5 | P·O4 2.5 | |

| Cement ratio, % | Clinker | Post-90s | Post-90s | Post-90s |

| limestone | 5 | 5 | 5 | |

| plaster | 5 | 5 | 5 | |

| Cement specific surface area, cm²/g | 3500 | 3500 | 3500 | |

| System output, t/h | 170 | 160 | 160 | |

| System power, kWh/t | 41 | 33 | 28 | |

| Annual energy saving (×10,000 yuan) | — | 400 | 700 | |

| Metal wear, g/t | 50 (steel ball) | 30 (steel ball + rolling surface) | 5 (roller + grinding table) | |

| drying capacity | weak | Moderate | strong | |

It can be seen from the table that the vertical mill system is superior to the ball mill and roller press system in terms of power saving. In terms of power saving, the following gives you an account:

| Economic benefit analysis: the economic benefits brought by the vertical mill system's high operating rate, power saving, and operation and maintenance costs |

|---|

| If one ton of cement saves 4.5kwh/t of electricity, produces 5000 tons of cement a day, works 300 days a year, and costs 0.7 yuan per kilowatt-hour of electricity, it can save electricity bills:4.725 million yuanPer year |

| Annual maintenance fee balance:3.66 million yuan |

| Maintenance cost balance per ton of cement:45,000 yuan |

| all:8.43 million yuan |

Considering long-term development and environmental protection, the production line based on cement vertical mill is the most suitable choice for investment income.

1. Pre-sales service

supplyComprehensive technical and business consulting services;

ProposalProvide our customers with the most suitable solutions and equipment;

designAnd make targeted products according to the special requirements of customers;

2. After-sales service

high inspectionequipment for each process,qualityfirst come;quickly &safedeliver goods; assistOur equipment foundation construction customers;schedulingEngineers install and debug equipment;trainOn-site front-line operators;oftenVisit customers to solve problems.

Our long-term strategic partners:

ArcelorMittal, Fl-Smith, Tata Group, POSCO, Germany CCE, Japan Chiba, Shanghai Baosteel, VAI, ASGT.

Packaging Details:The main machinery is packaged naked, and the spare parts are packaged in standard export wooden or steel boxes, which are suitable for long-distance transportation.

Shipping Details:Within 30--60 days after your payment or the time you request!

-

Professional lime production line lime kiln lime production factory

-

China 100TPD lime kiln for lime production line factory

-

Supply 100-2000tpd cement production line cement machinery manufacturing plant

-

Professional mini cement plant, cement production line construction project

-

Efficient Concrete Mixer Cement Mixer Force Action Mixer JS750

-

4.0×60 lime equipment rotary kiln, cement plant rotary kiln, roller table rotary kiln

-

Ex-factory price of advanced technology of Great Wall Cement Plant

-

New type ball mill sliding shoe bearing

-

6000tpd 42.5 Portland cement plant

-

China Manufacturer Rotary Kiln Cement Making Machine

Other Products

-

$5000000.00 / unit

$5000000.00 / unit