Chemical Drilling Stack Construction Drilling Mud Recovery System Mud Hydrocyclone Mud Desander

-

Supplier: Hunan Foundation Alpha Engineering Co., Ltd. -

Region: Hunan, China -

Contact: Mr Huang Hailing -

Price: $20000.00 / 1 - 1 units

$19000.00 / >=2 units -

Min. Order: 1 unit

| Showroom location: | not any | payment terms: | L/C, Western Union, T/T |

| Core component warranty: | 1 year | Sand purification: | More than 90% (-0.074mm grain size) |

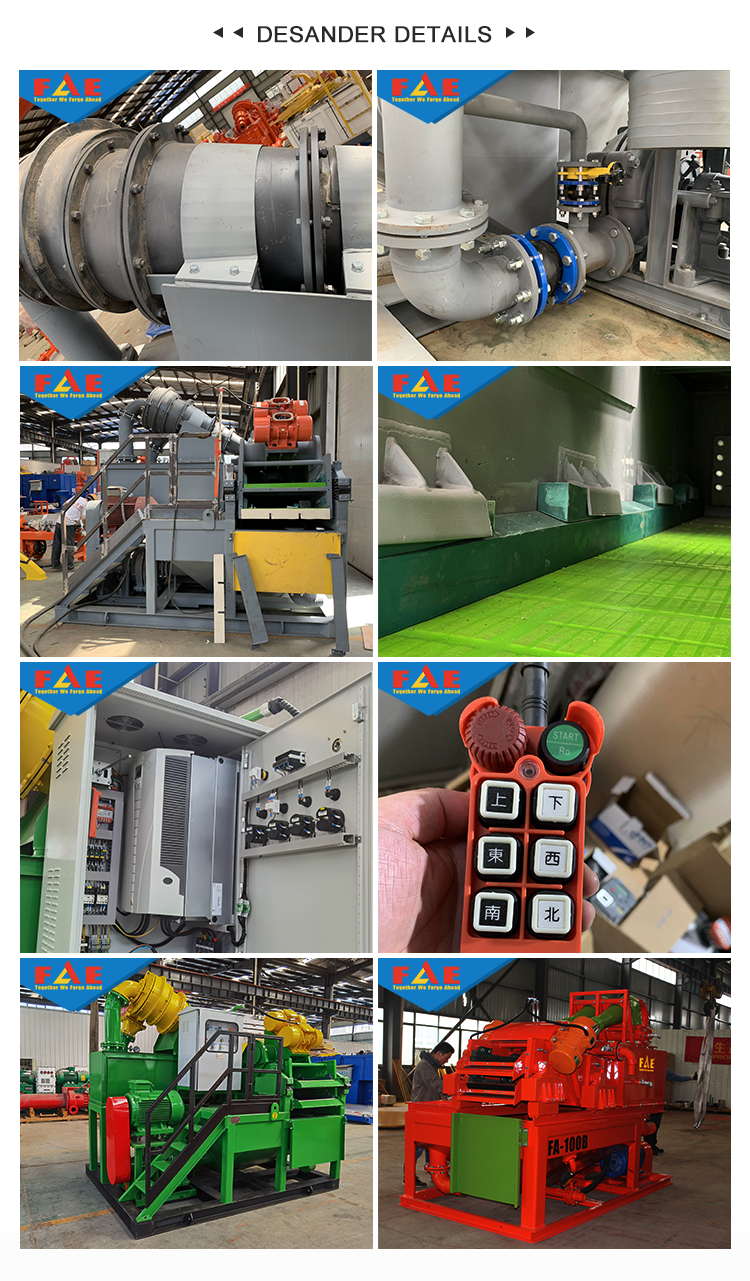

| Core components: | Cyclone separator, vibrating screen system, slurry pump and motor, electric control system | After-sales service provided: | Engineers available to service machinery overseas |

| Video shipment inspection: | if | Mechanical test report: | if |

| Mud handling capacity: | High | Packaging Details: | plastic film |

| Origin: | Hunan Province, China, Hunan Province, China | Shaker: | Simple operation, less failure |

| Screen vibration mode: | straight line | product: | Desander |

| Health status: | new | Supply capacity: | 10 units per month |

| brand: | Field Engineer | Marketing Type: | normal product |

| Sieve residue content: | less than 30% | Local service location: | not any |

| port: | China Port/Shanghai/Shenzhen | color: | According to customer needs |

| Applicable industries: | construction project | Warranty: | 1.5 years |

| Model | Maximum capacity | to sieve capacity |

maximum moisture content |

Mud max. Shenguang | strength | divided particle size |

Inlet size | Export size | weight | aspect |

| FA-20/30 | 20 | 5-10 | <30% | <1.4 | 9 | 30 | DN65(2.5") | DN100(4") | 2 | 2055*1730*2240 |

| FA-50/30 | 50 | 5-15 | 12.5 | 60 | 2.2 | |||||

| FA-100/60 | 100 | 20-50 | twenty four | DN100(4") | DN150(6") | 3 | 2862*1676*2433 | |||

| FA-150/60 | 150 | 32 | 3 | |||||||

| FA-200/60 | 200 | 25-80 | 48 years old | DN150(6") | DN250(10") | 5.5 | 4522*2192*2903 | |||

| FA-200/60 | 3161*2576*2903 | |||||||||

| FA-260/60 | 260 | 58 | 5.8 | 4522*2192*2903 | ||||||

| FA-260/60 | 3161*2576*2903 | |||||||||

| FA-400/60 | 400 | 75-240 | 100 | DN300(12") | 2XDN250(10") | 20.2 | 10705*4144*6536 | |||

| FA-500/60 | 500 | 120 | 20.8 |

feature:

1. Thoroughly purify the slurry, effectively control the suspension performance, reduce dnd interference accidents, and improve

Hole quality;

2. Realize the recycling of mud and save mud production materials; greatly reduce the transportation cost of waste mud

and pulping cost; 3. The effective separation of soil and residue by the equipment helps to improve the efficiency of hole formation;

4. Mud closed circulation puficotion mode and lower slag moisture content reduce the impact on the environment;

5. The purification effect of the double-layer screen is more than 50% higher than that of the single-layer screen structure.

Safe and convenient operation, simple maintenance, stable and reliable operation;

6. Reasonable design, compact structure, small footprint, prevent dry pump, and effectively prolong service life

Hydrocyclone feed pump;

7. The hydrocyclone is made of PU material, which has a long service life, light weight and easy maintenance

Q1: Are you a manufacturer?

A: Yes, we are a professional manufacturer of drilling rigs and their parts.

Q2: What does your company produce?

A1: Our company's main products are rotary drilling rigs, kelly, drilling buckets, augers, casing oscillators,

Desander and tri-cone bit, etc.

Q3: How about your delivery time?

A: Usually the delivery time is about 35 days, for some special cases, we can finish it within 2 weeks, it depends on

different products.

Q4: What payment methods do you accept?

A: We accept TT, L/C, D/A, Western Union.

Q5: What is the MOQ?

A: Small trial order is acceptable. Such as 1pcs, 2pcs...

Q6: Do you offer any benefits or discounts?

A: Yes, the price depends on different quantities, and different quantities will give you different prices.

Q7: What about your package?

A: We use standard export packaging, wrapped with plastic film+bag+carton+case.

Q8: Do you have free samples?

A: Yes, we can provide it for you, welcome to contact us for details.

-

Long service life mini dump truck electric narrow tunnel electric mini dump truck

-

45 Ton DR50C Articulated Mining Dump Truck

-

Turnkey competitive price dolomite magnesium oxide process production line

-

CE certified rock mine tunnel large capacity crawler slag loader/wheel loader

-

Cost-effective light mining dump truck 3 tons

-

Small alluvial 10tph gold ore processing plant with trommel for sale

-

Laboratory Laboratory Mineral Mining Small Mini Sample Pulverization Vibration Seal Pulverizer Grinder

-

Hot sale 4x4 diesel mini truck 6 tons mine underground dump truck mine dump truck for sale

-

7 ton mining trolley electric locomotive

-

ZQ-26 mine pneumatic rock loader, underground slag discharge loader ZQ-26, air rock loader ZQ-26 manufacturer