Water Bottle Blow Molding Machine 5 Gallon Bottle Making Machine Bottle Machine

-

Supplier: Taizhou Fupusi Machinery Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr John Tao -

Price: $3300.00 / 1 - 2 sets

$3100.00 / 3 - 4 sets

$2800.00 / >=5 sets -

Min. Order: 1 set

| All electrical components: | Siemens | PLC: | Siemens |

| Maximum bottle diameter (mm): | 290 mm | Origin: | Zhejiang, China |

| Bottle capacity (ml): | 20000ml | Dimensions (L*W*H): | 4800*1750*1850 |

| Voltage: | customer | Maximum bottle height (mm): | 490mm |

| Applicable industries: | Food and Beverage Factory | PLC brand: | Siemens |

| Rotary cylinder brand: | SMC | Supply capacity: | 300 sets per year |

| All cylinders: | SMC | application: | bottle |

| Mechanical test report: | if | Clamping system: | Servo Siemens |

| Main selling points: | famous brand motor | After-sales service provided: | 24 hours |

| payment terms: | Western Union, L/C, T/T, MoneyGram | Showroom location: | Thailand, United States, Brazil, Australia |

| Core component warranty: | 1 year | Year: | Year 2014 |

| brand: | Phops | Warranty: | 1.5 years |

| Core components: | PLC | Key words: | Blow Molding Machine Water Bottle Making Machine |

| touch screen: | Siemens | Packaging Details: | Export standard seaworthy packaging, using strong film |

| All action valves: | SMC | Video outbound inspection: | if |

| port: | Ningbo Port | Package preview: | |

| Plastic processing: | pet | Neck Diameter (mm): | 65 mm |

| Weight (kg): | 6500 kg | automation: | automatic |

| Health status: | new | Hollow part volume: | 10 ml to 25 liters |

Water Bottle Blow Molding Machine 5 Gallon Bottle Making Machine Bottle Machine

Semi-automatic series

FUPUSI-S Series Semi-automatic Blow Molding Machine

FUPUSI-S series blow molding machine can produce 0.2L, 0.3L, 0.5L, 0.6L, 1L, 1.5L, 5L, 7L, 10L, 12L, 20L, 30L and other shapes, suitable for carbonic acid, minerals, pesticides, Cosmetics, wide mouth and other plastic PET/PP containers. They have all the advantages of FUPUSI series blow molding machines: low scrap rate, high speed, stable operation and easy operation.

set up

A). PLC: Mitsubishi

b). Touch screen: WEINVIEW

*Semi-automatic bottle blowing machine series:

1. 2L semi-automatic bottle blowing machine (2 cavities)

2. 1L semi-automatic bottle blowing machine (4 cavities)

3. 5L semi-automatic bottle blowing machine (1 cavity)

4. 5L semi-automatic bottle blowing machine (2 cavities)

5. 20L semi-automatic bottle blowing machine (1 cavity)

6. Semi-automatic PP bottle blow molding machine (2 cavities)

7. PC bottle semi-automatic blow molding machine (1, 2 cavities)

Automatic series

Phops-FSeries bottle blowing machines can produce 0.2L, 0.3L, 0.5L, 0.6L, 1L, 1.5L, 5L, 20L and other plastic PET/PP containers of carbonated, mineral water, pesticides, cosmetics, and wide mouth. It has all the advantages of AI series bottle blowing machines: low reject rate, high speed, stable operation and convenient operation.

set up

A). Servo motor: Siemens

b). Action valve: SMC

C). Cylinder: SMC

d). PLC: Siemens

e). Electrical components: Siemens

F). High pressure blow valve: MAC

G). Oil water separator: SMC

h). Touch screen: Siemens

*Automatic bottle blowing machine series:

1. Fully automatic mineral water bottle blowing machine (2 cavities, 4 cavities, 6 cavities)

2. Fully automatic cosmetic bottle blowing machine (2 cavities & 4 cavities & 6 cavities)

3. Fully automatic carbonated bottle blowing machine (2 cavities, 4 cavities, 6 cavities)

4. Fully automatic bottle blowing machine (1 cavity, 2 cavities, 4 cavities, 6 cavities)

5. 5L oil bottle automatic blow molding machine (1 cavity & 2 cavity)

6. 10L oil bottle automatic blow molding machine (1 cavity, 2 cavity)

7. 20L oil/water bottle automatic blow molding machine (1 cavity & 2 cavity)

We will be happy to provide you with more details if required.

Please let us know if we can be of any further assistance.

....

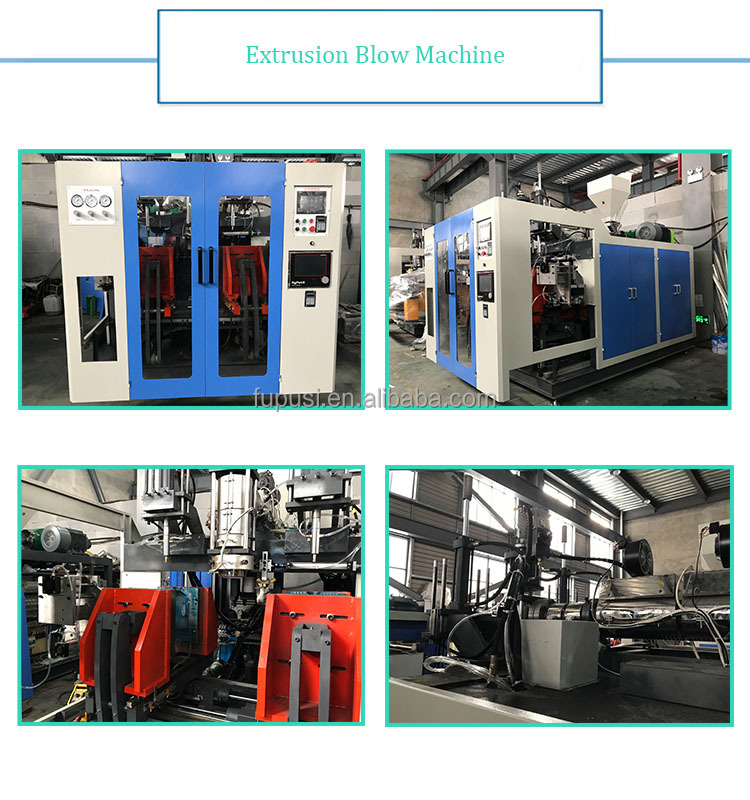

Squeeze Blow Series

Forps machineryAvailable in packaging containers with volumes from a few milliliters to 100 liters, as well as large containers with capacities up to 120 liters. The machines and molds of Fupus Machinery make the manufacture of blow molded products simple, whether with or without continuous or accumulator parison heads, with technologies such as hydraulic or hybrid drives. The close cooperation between Artin and its clients has contributed to its success.

Forps machines include double station continuous duty series extrusion blow molding machines for 100ml to 10L containers and single station hopper extrusion blow molding machines for 12L to 120L containers.

FPS-D series is a two-stage extrusion blow molding machine for containers from 5ml to 10L, with high reliability, excellent efficiency and flexibility to meet different customer requirements. The machine can process a wide variety of materials including HDPE, LDPE, PP, PVC, TPU, PETG and others. Compared with the S-series machines, the D-type machines can produce faster per hour. The FPS-D machine covers the complete production range from the smallest ampoules or tubes to beverage packaging, cosmetic containers, wide mouth containers and multilayer containers with visible stripe lines.

1. Suitable for producing 1L-12L fuel bottles, lubricating oil bottles, etc.

2. The inside of the die head is smooth, the curved flow channel has no dead angle, and the inside and outside of the finished product are smooth without lines.

3. The effect of multi-layer co-extrusion, the visible line design of the finished product can be selected to ensure uniform layer thickness. Straight visible lines of uniform width at the top and bottom.

4. The machine can be equipped with automatic deburring, finished product take-out device, waste and finished product conveying device, in-mold label, leak detector.

5. This model can be upgraded to a "hybrid type". The moving part of the carriage is designed with a servo motor to achieve no noise, easy operation, accurate positioning, and fast centering of the mold

*Small blow molding machine series:

1. Production 2L

2. Can produce 2L-5L

3. Production 5L

4. Production of 10L

*Large blow molding machine series:

1. Can produce 12L-18L

2. Can produce 20L-40L

3. Can produce 50L-60L

4. Can produce 70L-90L

5. Can produce 100L-120L

• Training

The seller trains two to three operators free of charge. (Transportation and hotel expenses are borne by the buyer.)

• Installation and testing

The buyer should place the machine at the correct location and notify the supplier when the machine arrives at the buyer's factory.

The supplier sends a special person to conduct a test run on the machine until it runs normally.

The buyer bears the cost of round-trip air tickets, accommodation, hotels, etc.

When the buyer leaves the factory, he needs to pay the labor cost of the technician at USD 140/day/person until he leaves the customer's factory.

•ensure

Our guarantee is valid for 18 months.

If the failure is caused by the quality of the machine itself, we will troubleshoot it for free.

We will be happy to answer any further questions you may have.

-

PET Blow Molding Machine Stretch Blow Making Machine Blow Molding Machine Plastic Jar Bottle 1 2L 5 Gallon Liter

-

Semi-automatic blow molding machine with cheap price

-

3L can blow molding machine semi-automatic pet DY-1200A milk can blow molding machine

-

factory supply 30ml 50ml 60ml 80ml 100ml 120ml 150ml Small plastic spray bottle making machine for cosmetic packaging

-

Water Bottle Making Machine Semi Automatic PET Blow Molding Machine Blow Molding Machine

-

High Quality Low Price Four Cavity 1800-2000 BPH Semi Automatic PET Plastic Blow Molding Machine Price

-

2022 New Design 500ml PET Bottle Stretching Automatic Plastic Blow Molding Blow Molding Machine 200ml 1500ml 1800ml 2000ml

-

plastic molding machine small machine for blowing plastic bottles

-

Fully automatic PET blow molding machine bottle mold

Other Products

-

$3300.00 / set

$3300.00 / set -

$35000.00 / set

$35000.00 / set -

$10000.00 / set

$10000.00 / set -

$420.00 / piece

$420.00 / piece -

$15000.00 / set

$15000.00 / set -

$18200.00 / set

$18200.00 / set